A kind of metamaterial based on ceramic substrate and preparation method thereof

A technology of ceramic substrates and metamaterials, applied in the field of metamaterials, can solve the problems of difficult to meet the types of microstructure processing and low shape accuracy, and achieve the effect of simple manufacturing process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

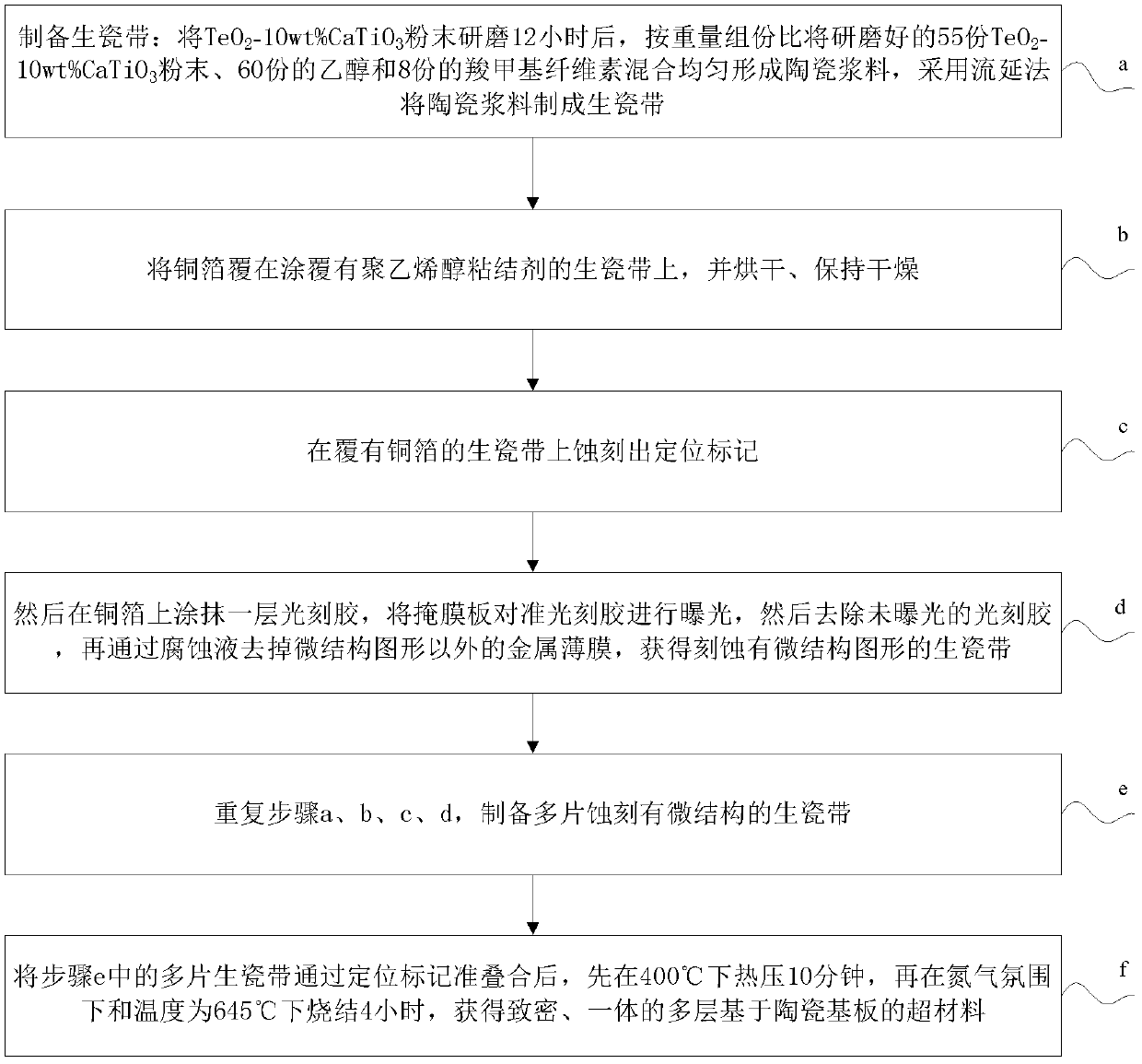

[0029] The preparation method of the metamaterial based on the ceramic substrate of the present invention comprises the following steps:

[0030] a. Preparation of raw porcelain tape: After grinding the low-temperature sintered ceramic powder for 4-24 hours, mix 40-60 parts of low-temperature sintered ceramic powder, 50-30 parts of solvent and 50-30 parts of binder according to the weight component ratio 1. Mix uniformly to form a ceramic slurry, the prepared ceramic slurry is a fluid substance with a certain viscosity, and the ceramic slurry is made into a green ceramic tape by casting method;

[0031] b. Cover the metal film on the green ceramic belt coated with the adhesive 2, and dry it and keep it dry; the metal film can be copper foil, gold foil, silver foil or aluminum foil;

[0032] c. Etching positioning marks on the green ceramic tape covered with metal film;

[0033] d. Etching microstructure patterns on the metal film by etching technology;

[0034] Apply a layer...

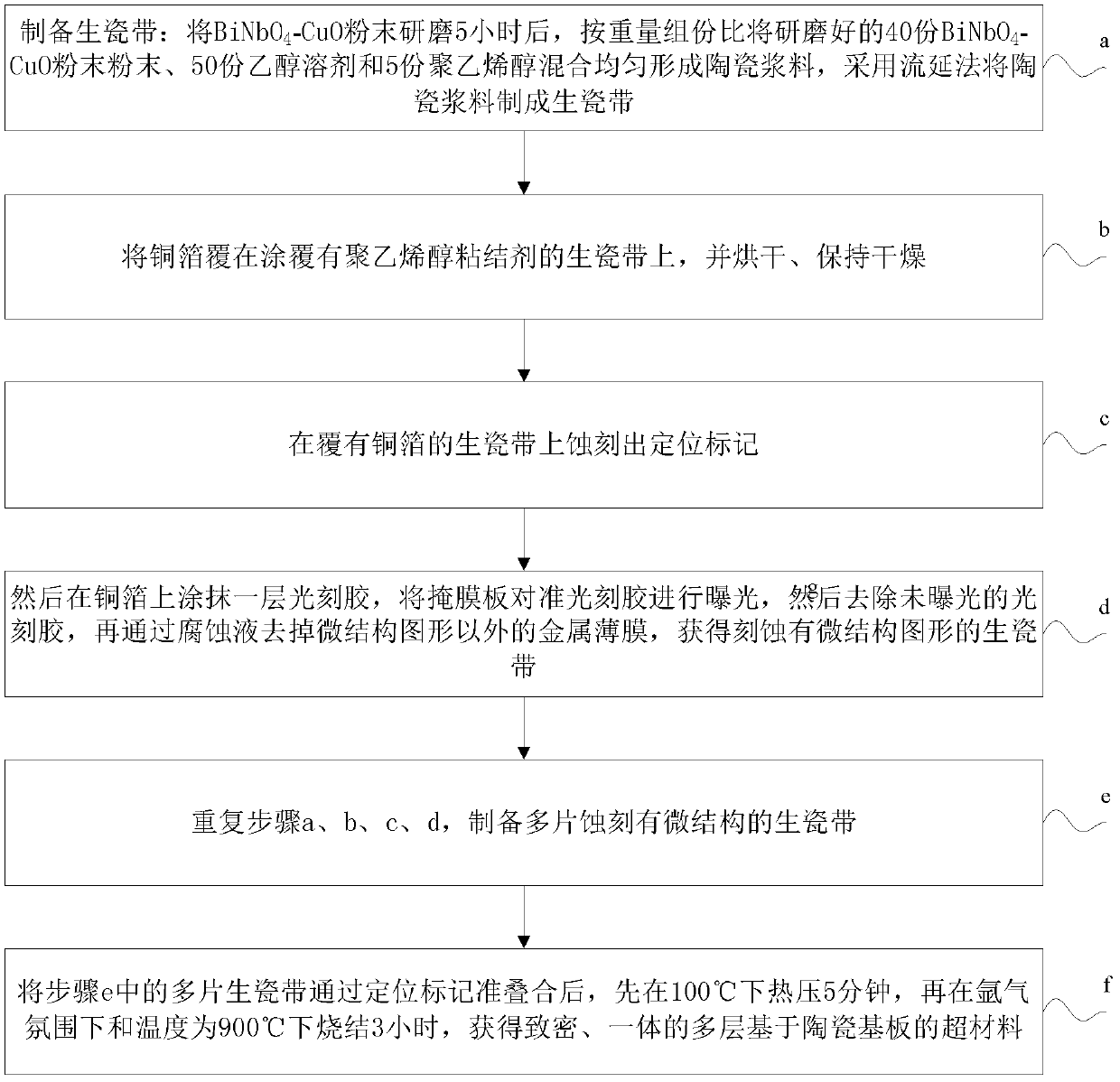

Embodiment 1

[0041] Embodiment one: if figure 1 shown

[0042] a. Preparation of green ceramic tape: BiNbO 4 After grinding 0.5wt% Cu powder for 5 hours, the ground 40 parts of BiNbO 4 -0.5wt% Cu powder, 50 parts of ethanol solvent and 5 parts of polyvinyl alcohol are mixed uniformly to form a ceramic slurry, BiNbO 4 -0.5wt% Cu powder is used as the ceramic matrix material, polyvinyl alcohol is used as the binder, and the prepared ceramic slurry is a fluid substance with a certain viscosity, and the ceramic slurry is made into a green ceramic tape by casting method;

[0043] b. Cover the copper foil on the raw ceramic belt coated with polyvinyl alcohol adhesive, and dry it and keep it dry. The adhesive used can be the same as the adhesive used to prepare the ceramic slurry Agent also can be other binding agent, as carboxymethyl cellulose; What select for use in the present embodiment is the same binding agent as in step a;

[0044] c. Etching positioning marks on the green porcelain ta...

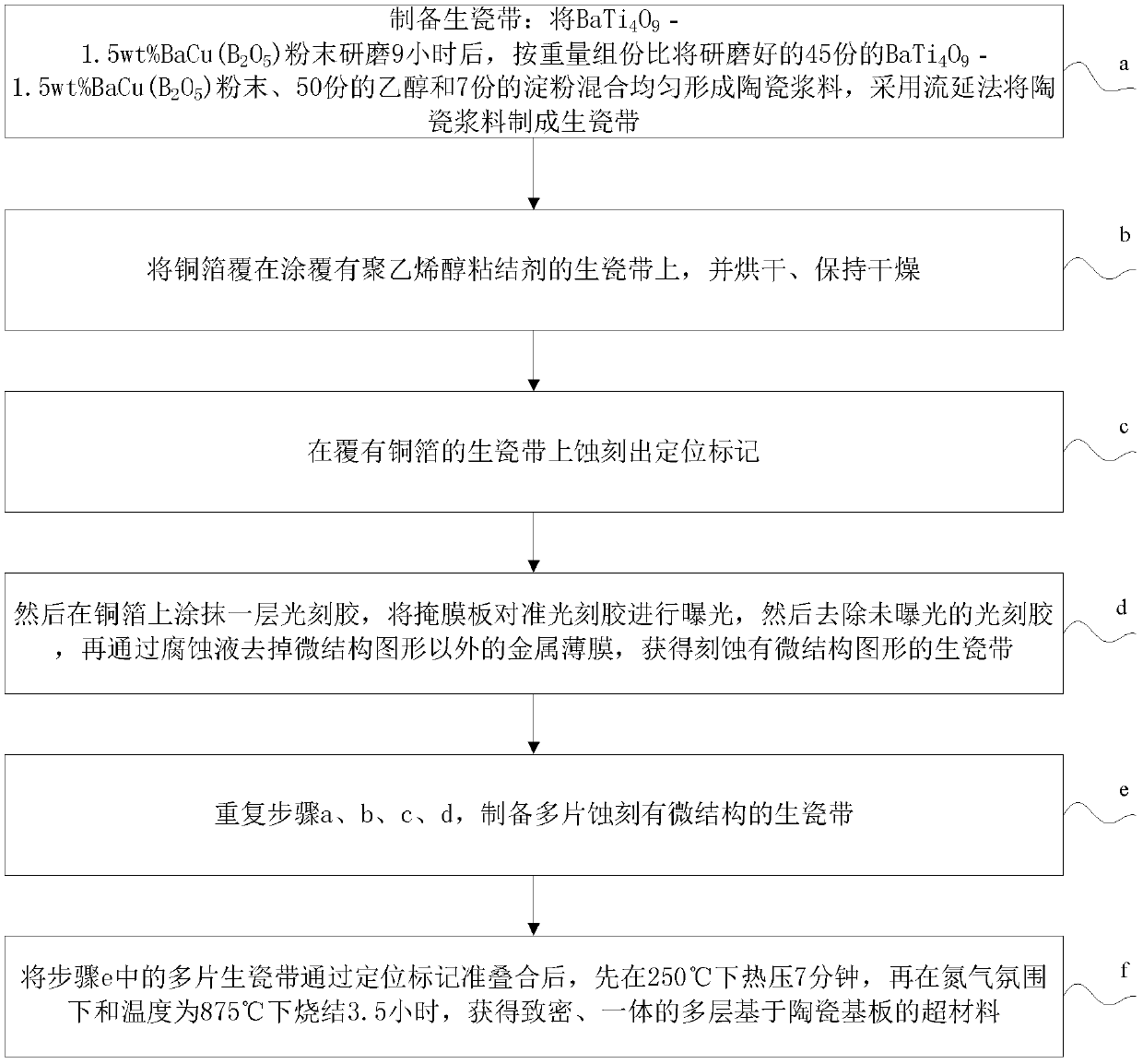

Embodiment 2

[0048] Embodiment two: if figure 2 shown

[0049] a. Preparation of green ceramic tape: BaTi 4 o 9 -1.5wt% BaCu(B 2 o 5 ) powder after grinding for 9 hours, the BaTi of 45 parts will be ground by weight component ratio 4 o 9 -1.5wt% BaCu(B 2 o 5 ) powder, 50 parts of ethanol and 7 parts of starch are mixed evenly to form ceramic slurry, BaTi 4 o 9 -1.5wt% BaCu(B 2 o 5 ) powder as a ceramic matrix material, starch as a binder, and the prepared ceramic slurry is a fluid substance with a certain viscosity, and the ceramic slurry is made into a raw porcelain tape by casting method;

[0050] b. Cover the copper foil on the raw ceramic belt coated with polyvinyl alcohol adhesive, and dry it and keep it dry. The adhesive used can be the same as the adhesive used to prepare the ceramic slurry Agent also can be other binding agent, as carboxymethyl cellulose; What select for use in the present embodiment is the same binding agent as in step a;

[0051] c. Etching position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com