Plastic box cleaning and dust removal device

A technology of dust removal device and plastic box, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of many corners around the plastic box, labor costs, and easy leakage of wiping, etc., to achieve saving Labor costs and auxiliary equipment costs, the effect of realizing reuse and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

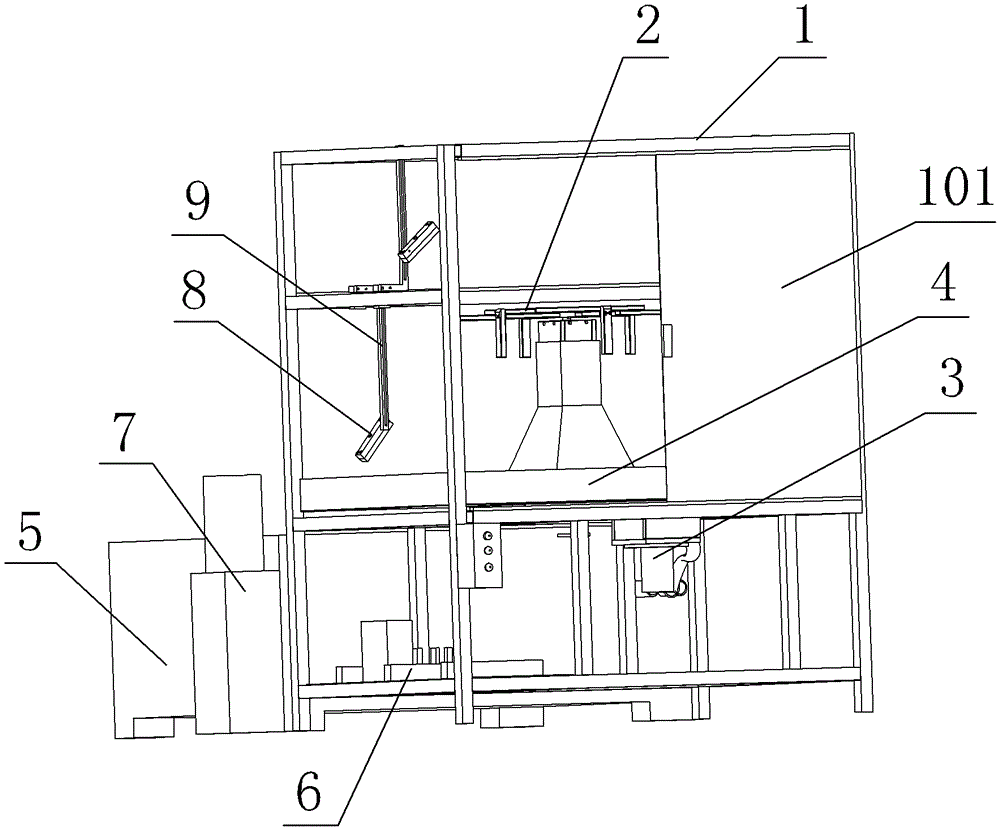

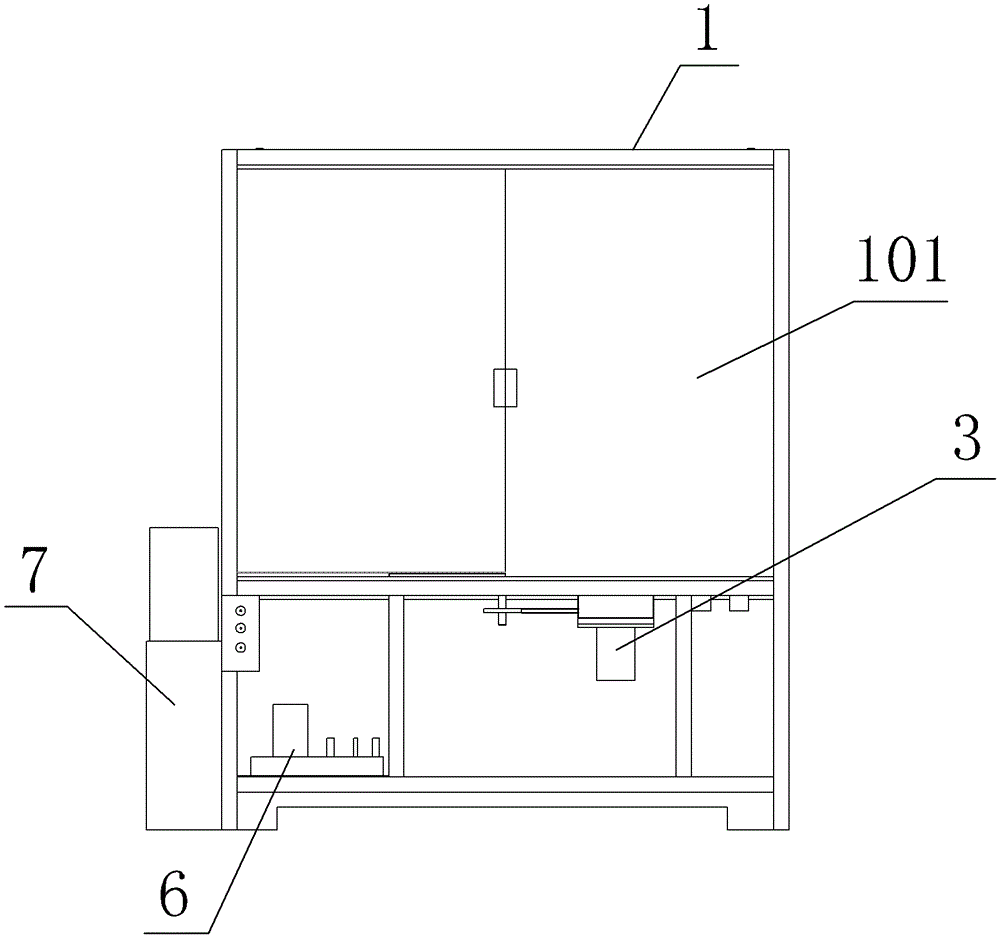

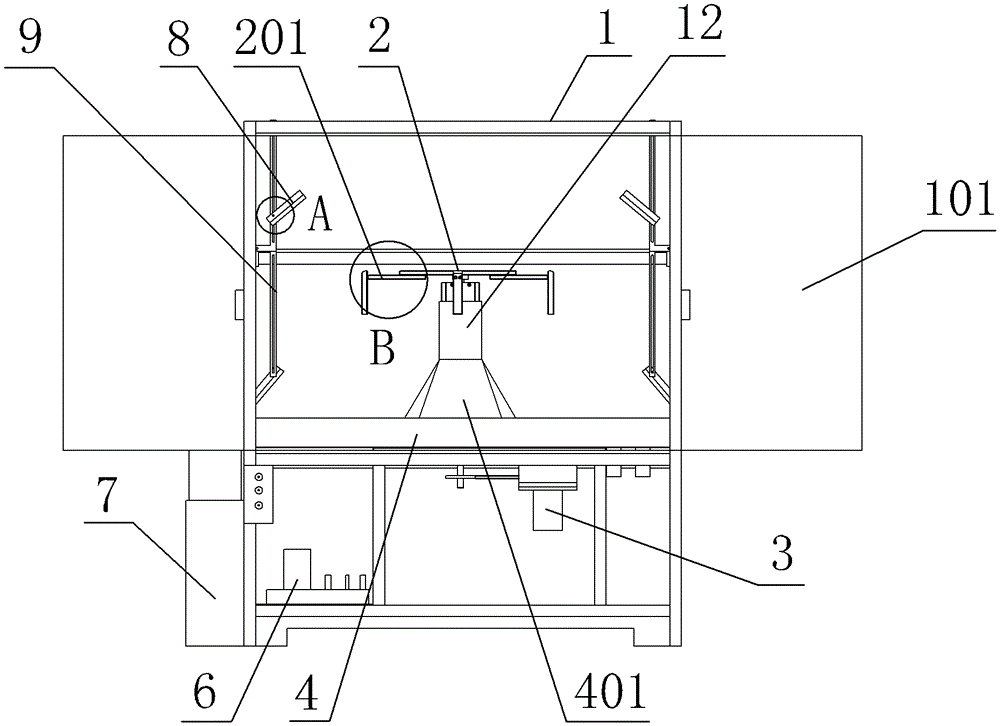

[0032] refer to Figure 1 to Figure 7 As shown, the present invention discloses a rubber box cleaning and dedusting device, which can be used to clean the rubber box. It includes a frame 1 with a chamber, and a rotary fixing device 2 for fixing the rubber box 10. A driving device 3 for driving the rotary fixture 2 to rotate, a high-pressure water pump system 7, a water storage device 5 for storing water, a water recovery device 4, and a device for controlling the above-mentioned driving device 3 and the high-pressure water pump system 7 The control device 6, wherein, the frame 1 is provided with a waterproof airtight door that can seal the chamber, in order to ensure that the chamber of the frame 1 is well sealed and achieves no leakage, it can be arranged on the inner wall or outside of the chamber Waterproof sealing cloth, after the waterproof sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com