Wheel-clamping device for a wheel-service-machine and method for reversibly clamping a wheel on a wheel-clamping device for a wheel-service-machine

A clamping device, wheel technology, applied in the direction of fixed wheel device, wheel, tire installation, etc., can solve the problem of installation is not, time-consuming, user-friendly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

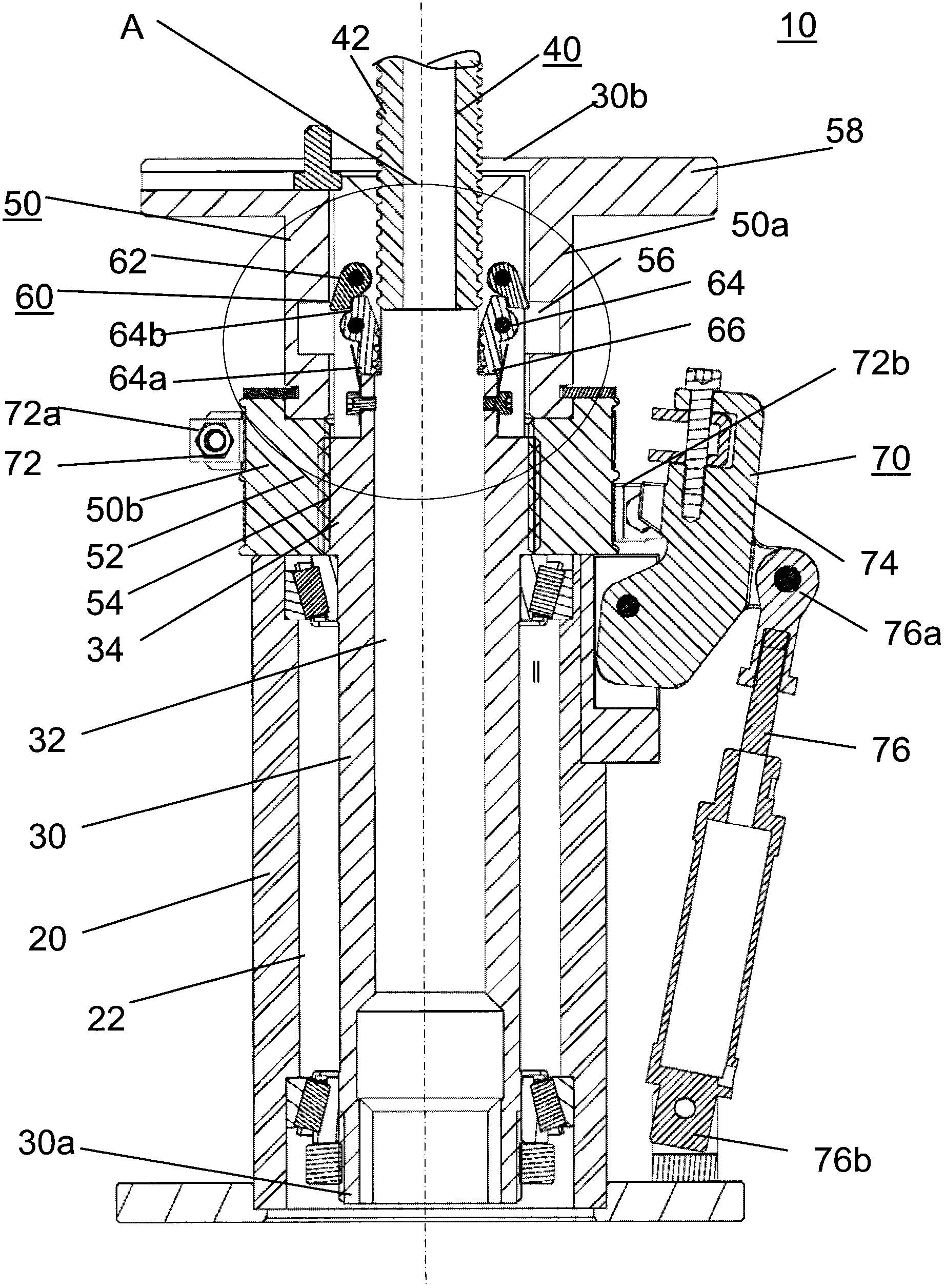

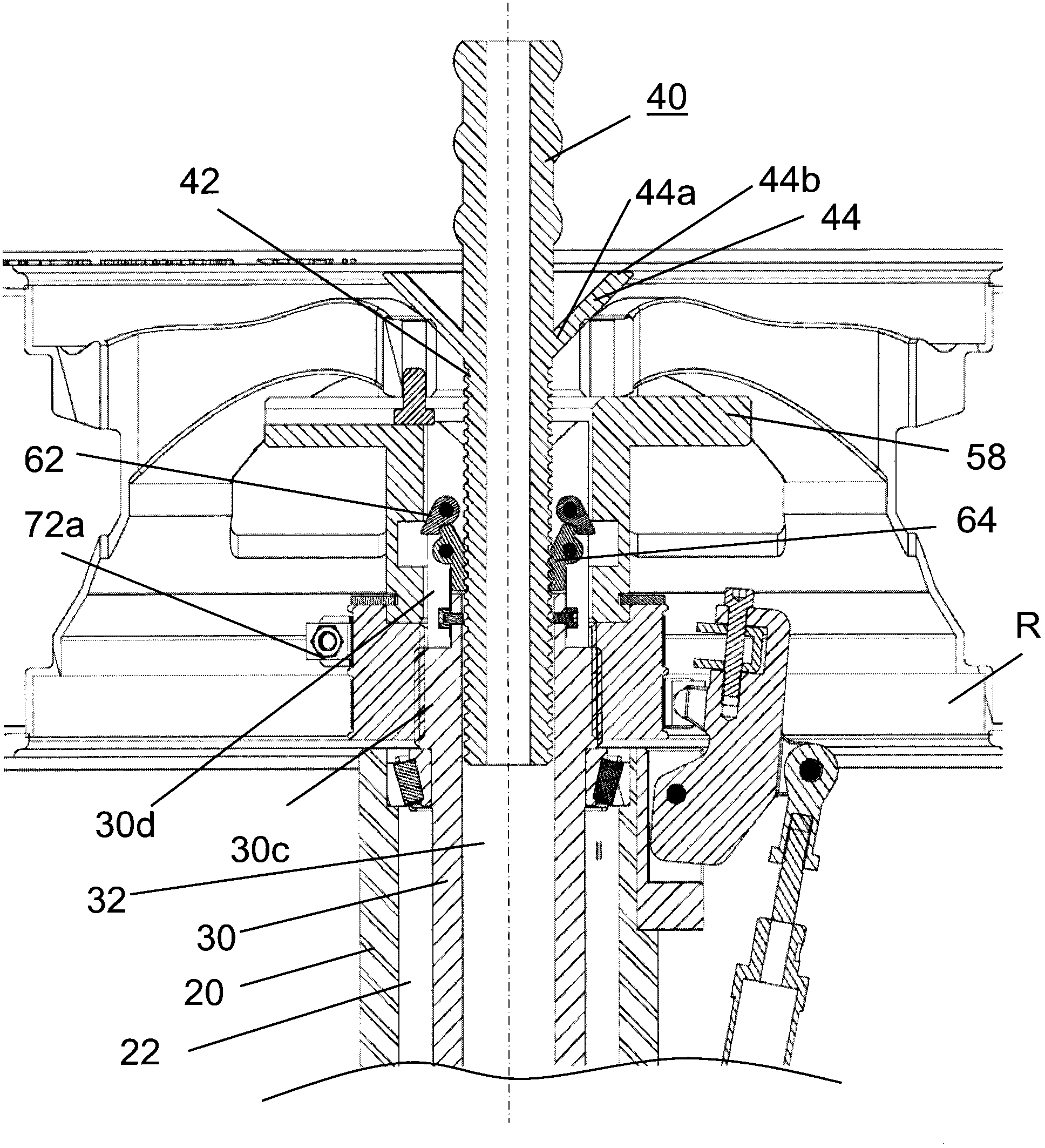

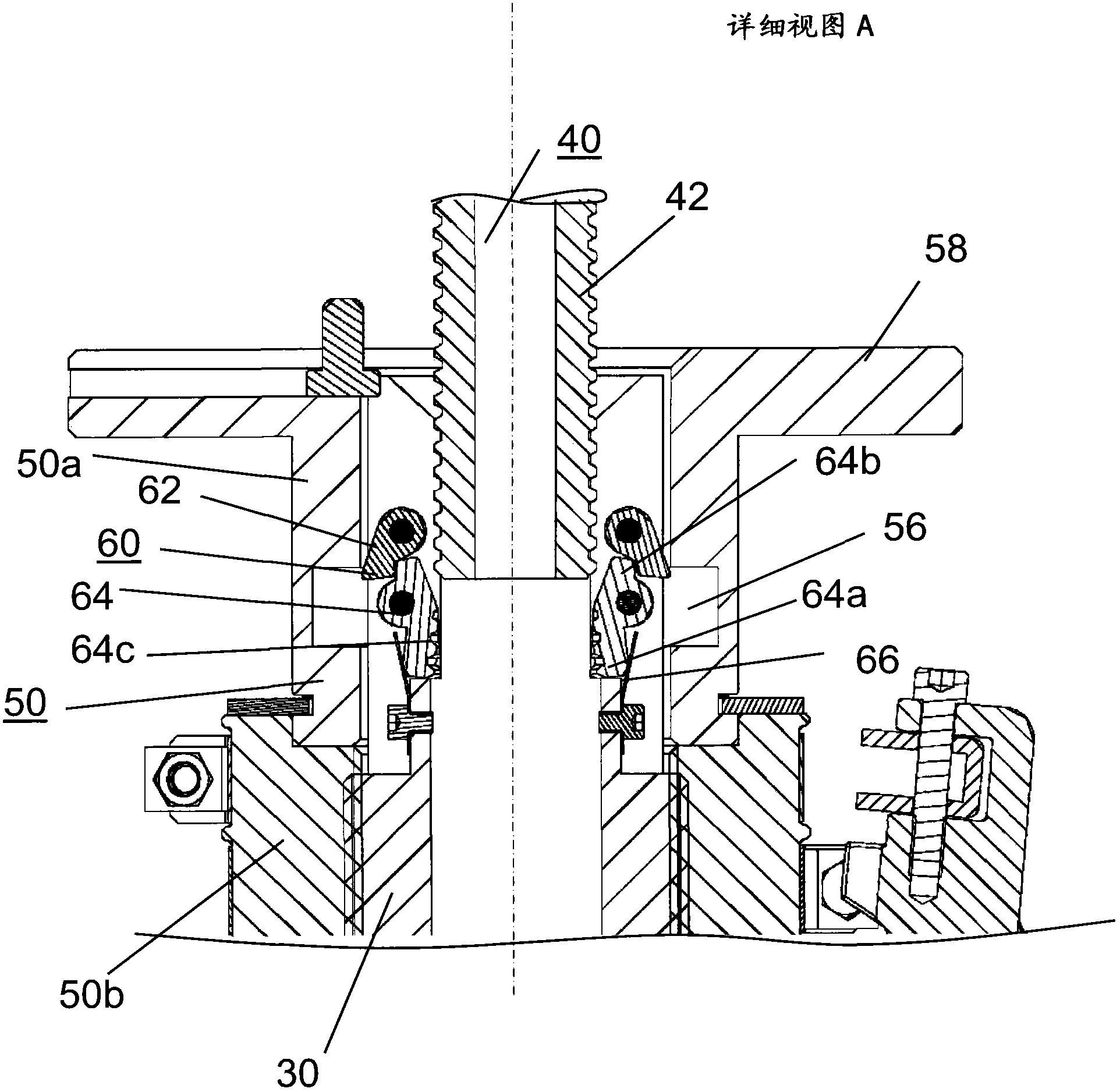

[0064] In the first embodiment of the present invention, Figures 1 to 3 The wheel clamping device 10 shown in the figure comprises, respectively as main components, a frame 20, an arbor 30, a fixing element 40 for temporarily fixing the wheel rim R of a tire to be mounted or removed to the wheel clamping device 10, a bushing 50 , clamping tool 60 and stop / hold tool 70 . Hereinafter, these components will be described in detail.

[0065] The frame 20 is formed from a cylindrical tube, preferably made of steel. A tubular frame 20 , rigidly attachable to the machine frame of a wheel servicing machine (not shown) provided with the inventive wheel clamping device 10 , rotatably supports a spindle 30 in its cylindrical through-hole 22 , for example by means of roller bearings.

[0066] A spindle 30, also preferably made of steel, is connected to the drive unit, figure 1 The drive unit is not shown. The drive unit can be formed by an active drive. Preferably, the drive means is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com