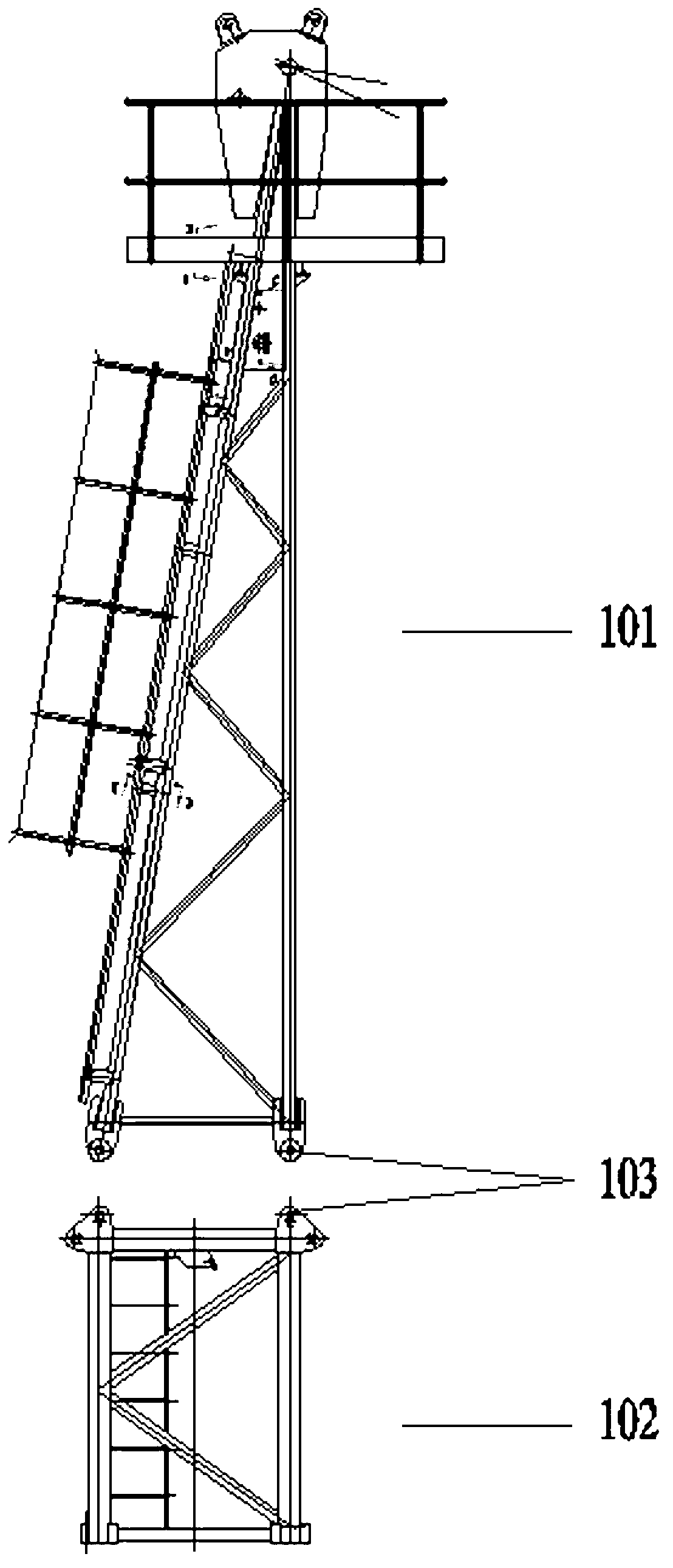

Tower top assembly of tower crane

A technology of towers and components, applied in cranes and other directions, can solve the problems of easy wear and tear of pin holes, affecting the normal operation of tower cranes, and increasing on-site installations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

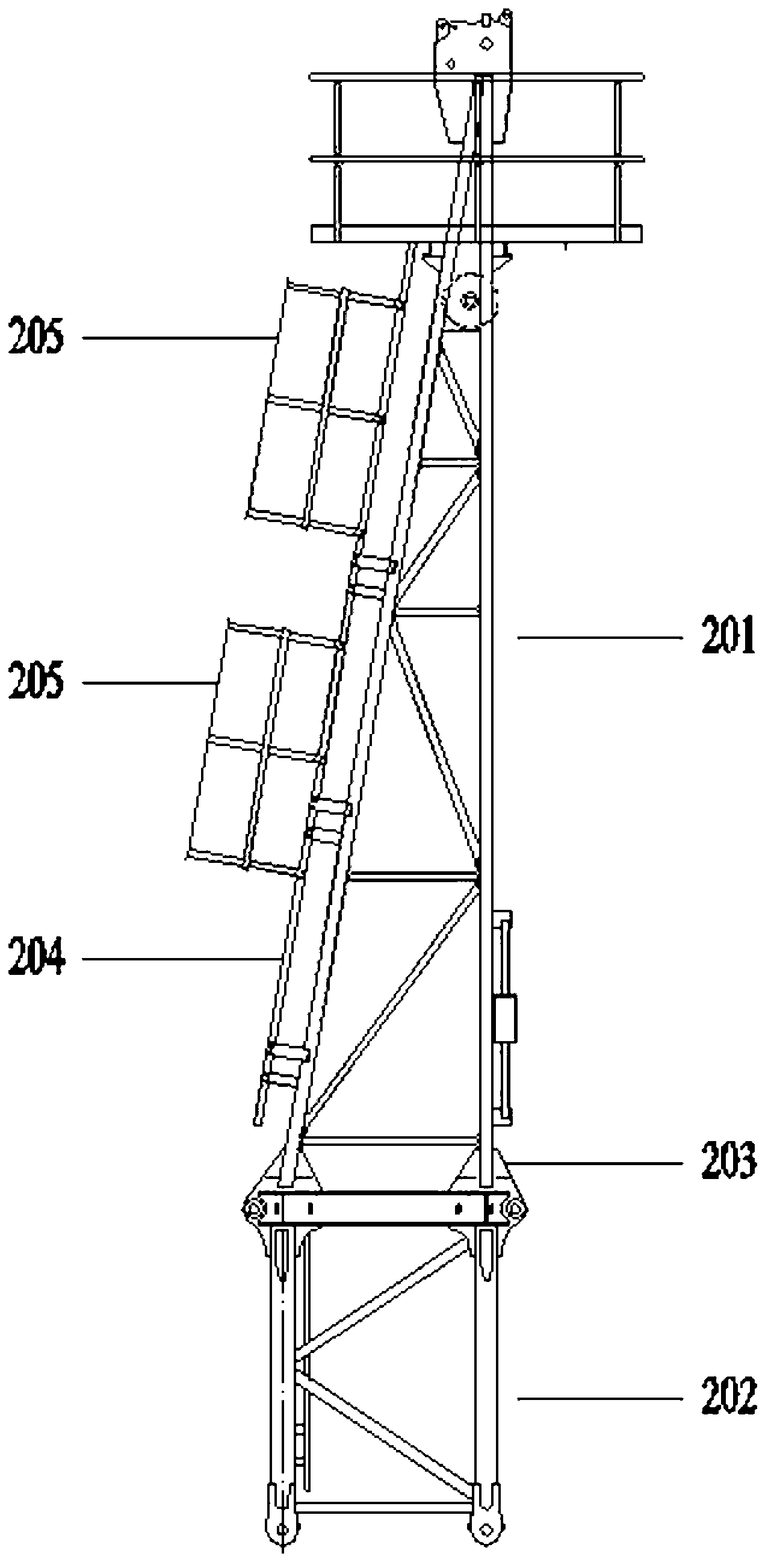

[0014] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0015] refer to figure 2 , The tower top assembly of the tower crane of the present invention includes: a tower top 201 and a standard section 202 connected to the bottom of the tower top 201, wherein the tower top 201 and the standard section 202 are welded as one.

[0016] In the present invention, the tower top 201 and the standard section 202 are connected by welding, replacing the original two parts connected by a pin shaft to form a whole, reducing the link of pin shaft installation in the installation process, and avoiding the phenomenon of pin hole wear. Use reliability is stronger.

[0017] As a preferred solution, a rib plate 203 is welded between the tower top 201 and the standard section 202 to strengthen the strength of the connection between the tower top 201 and the standard section 202 and ensure the stability of the tow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com