Mounting method of fabricated inner wall surface corner plates

An installation method and corner board technology, applied in the field of housing and residential decoration, can solve the problems of difficult to achieve technical quality effect acceptance requirements, unfavorable corner board installation and formation, unsightly corner board formation effect, etc., so as to shorten the installation period and improve the The quality of work and the effect of improving the quality of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0029] A method for installing a prefabricated inner wall corner panel includes the following steps:

[0030] 1) According to the process requirements, smooth and harden the inner wall surface at the corner of the wall of the prefabricated building; at least the inner wall surface where the corner board is to be installed needs to be smoothed and hardened;

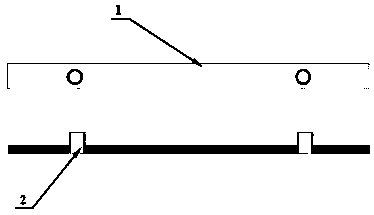

[0031] 2) Make a nail hole positioning strip with more than one guide nail hole;

[0032] 3) On the inner wall surface of the corner of the wall, that is, the vertical longitudinal wall surface and the horizontal wall surface, corresponding to the distance between the guide nail holes, the horizontal wall pin installation holes and the longitudinal wall pin installation holes are respectively drilled;

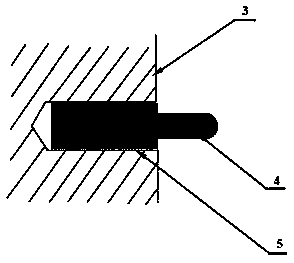

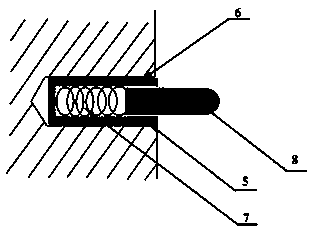

[0033] 4) The nail hole positioning strip is placed on the longitudinal wall, and the one-piece pin is inserted into the longitudinal wall pin installation hole through the guide nail hole; the nail hole positioning strip i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com