Patents

Literature

62results about How to "Meet the requirements for installation and use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

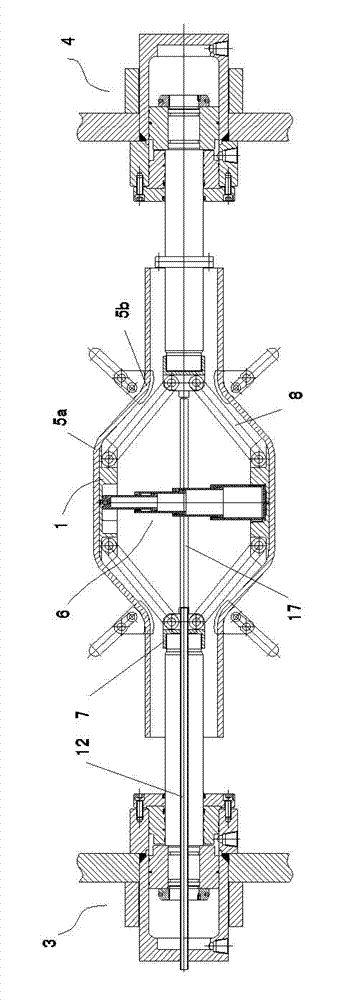

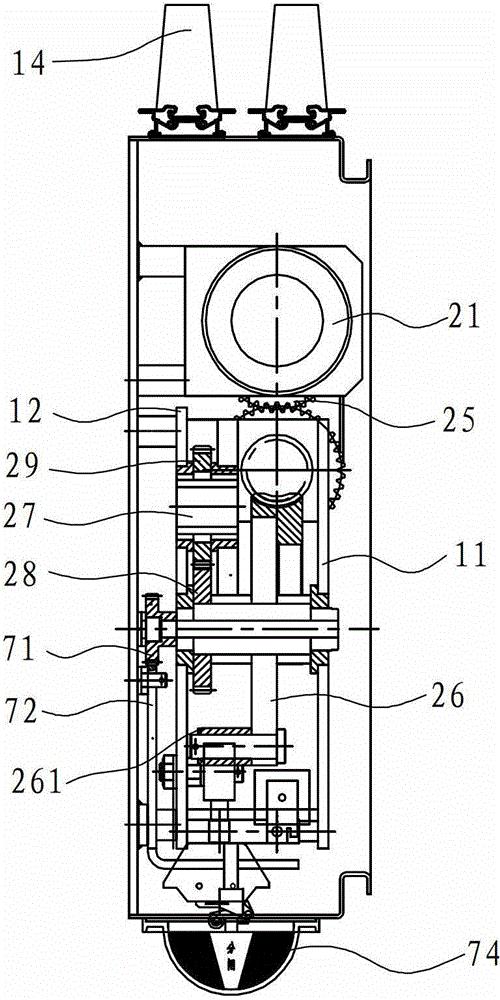

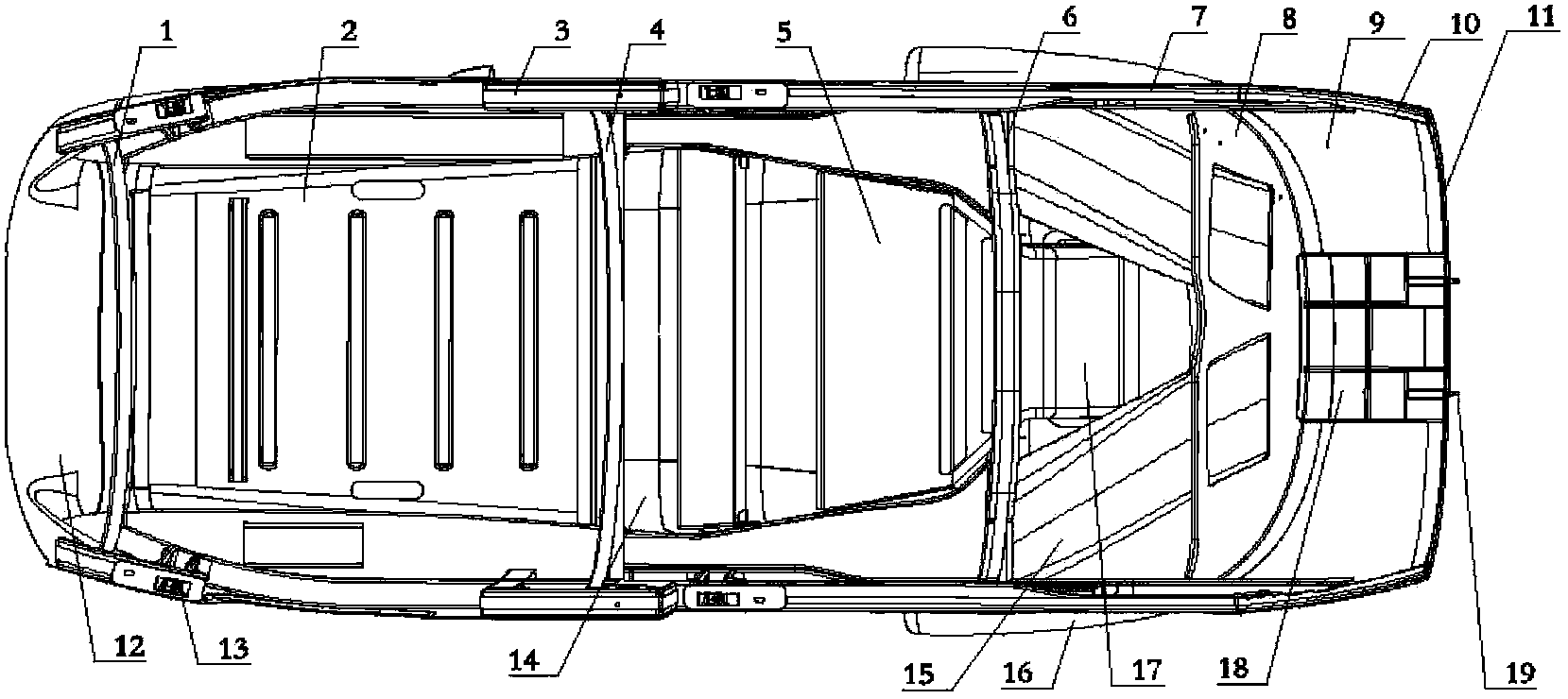

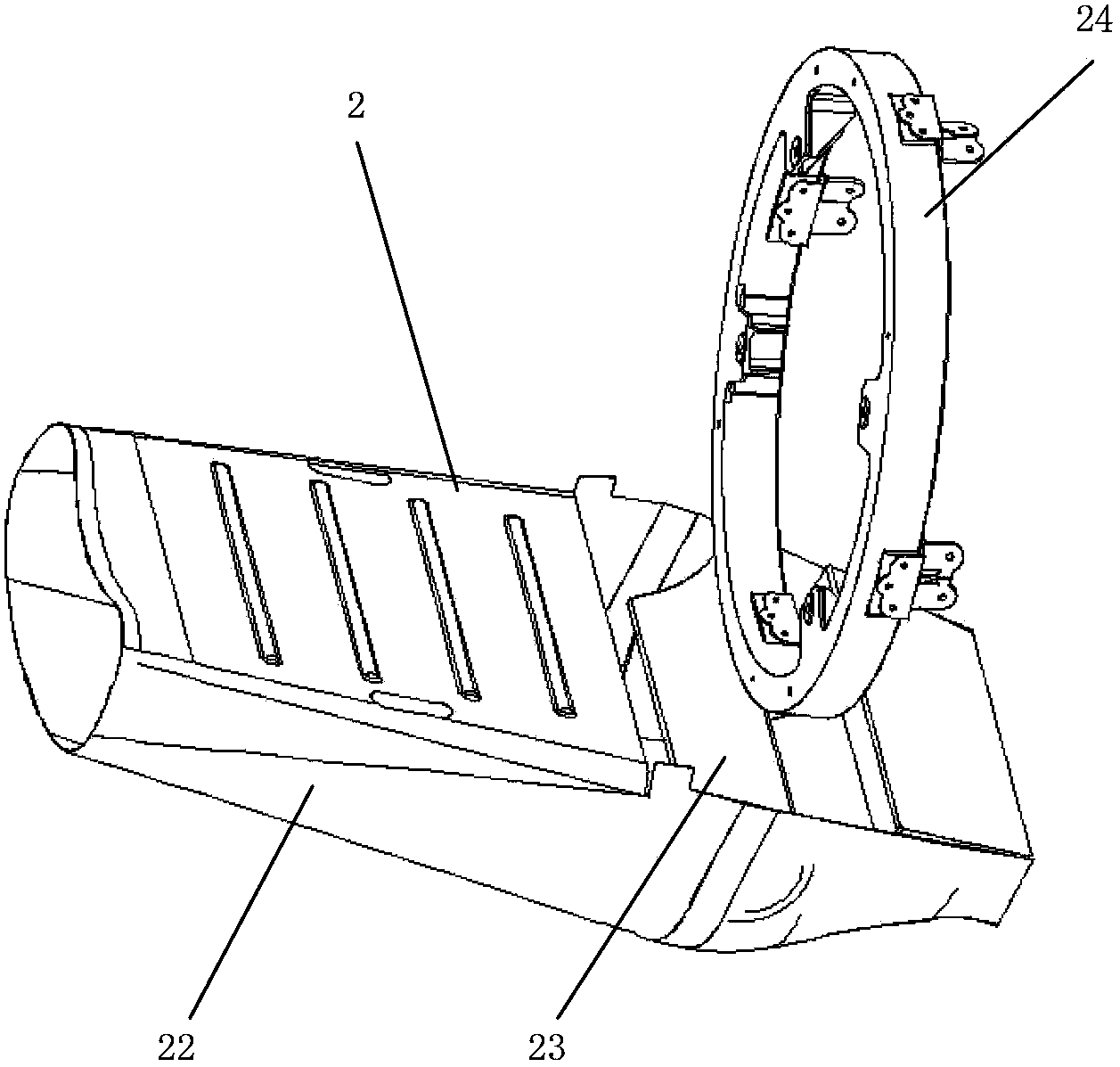

Overall composite mechanical spiral type bulging device for car drive axle

InactiveCN102886465ABulging inner mold provides bulging realizationBulging achievedShaping toolsVehicle componentsHydraulic cylinderCar driving

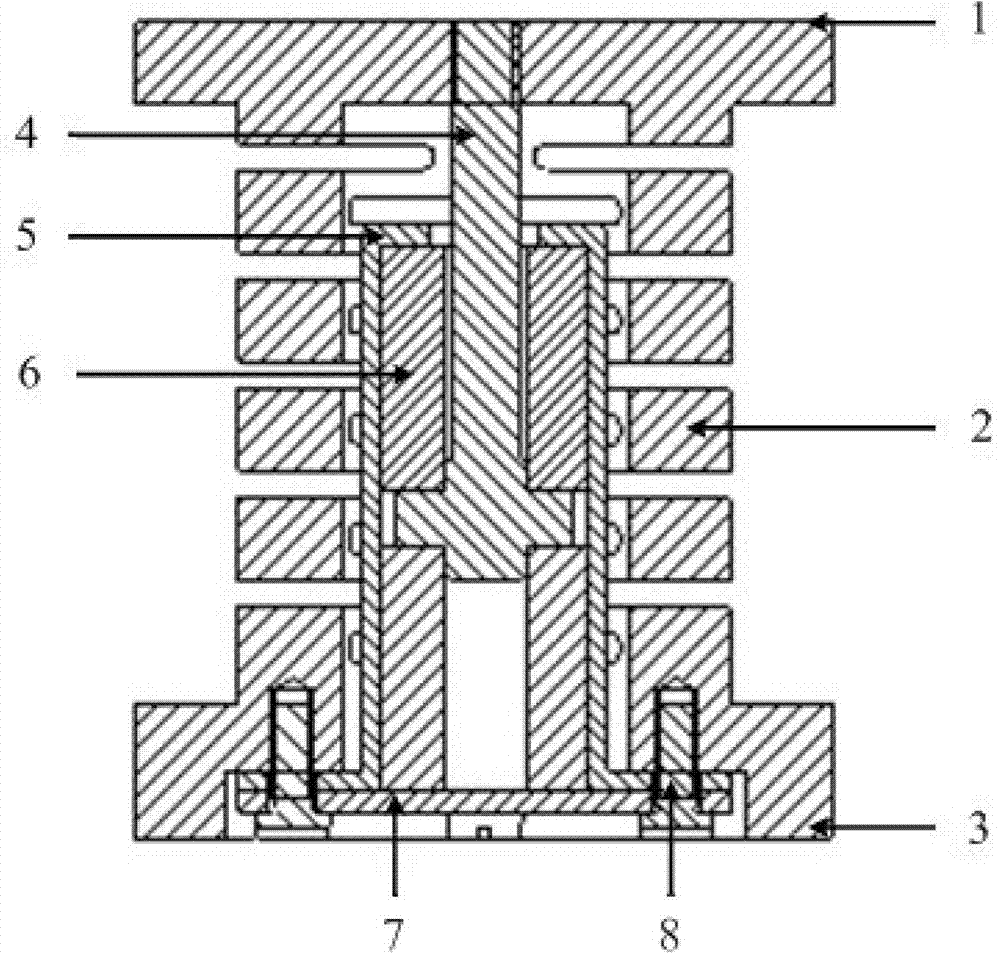

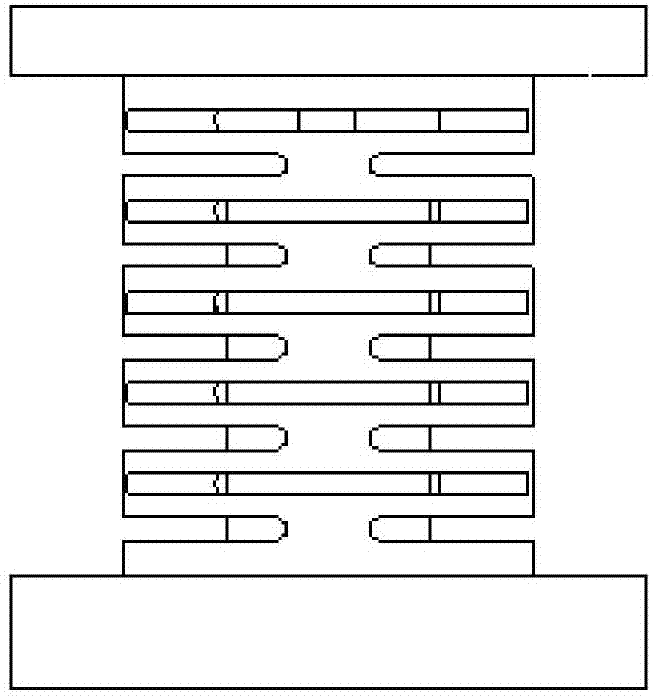

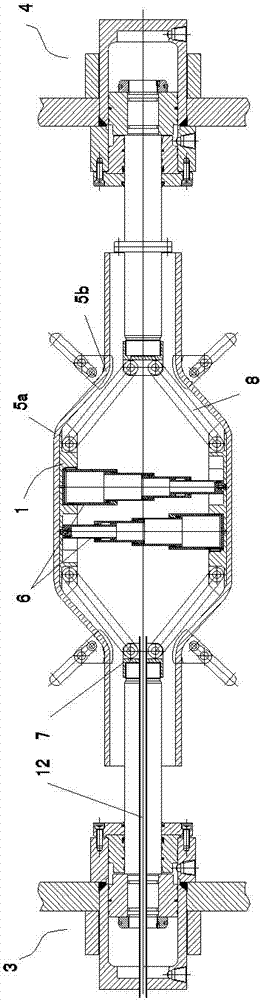

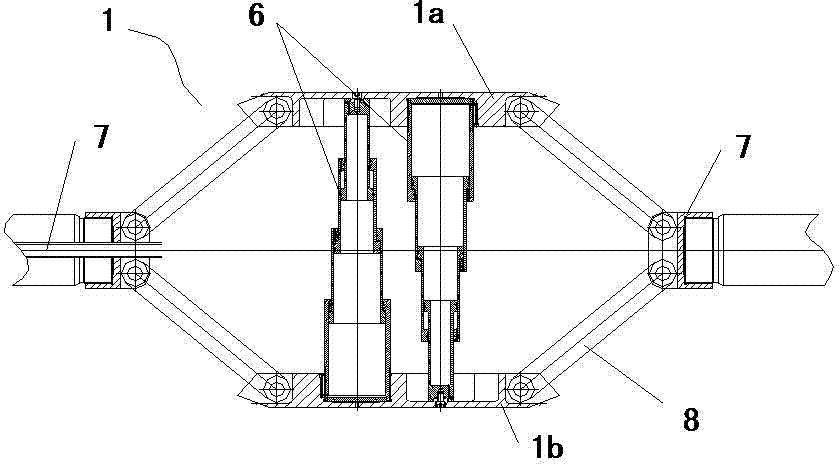

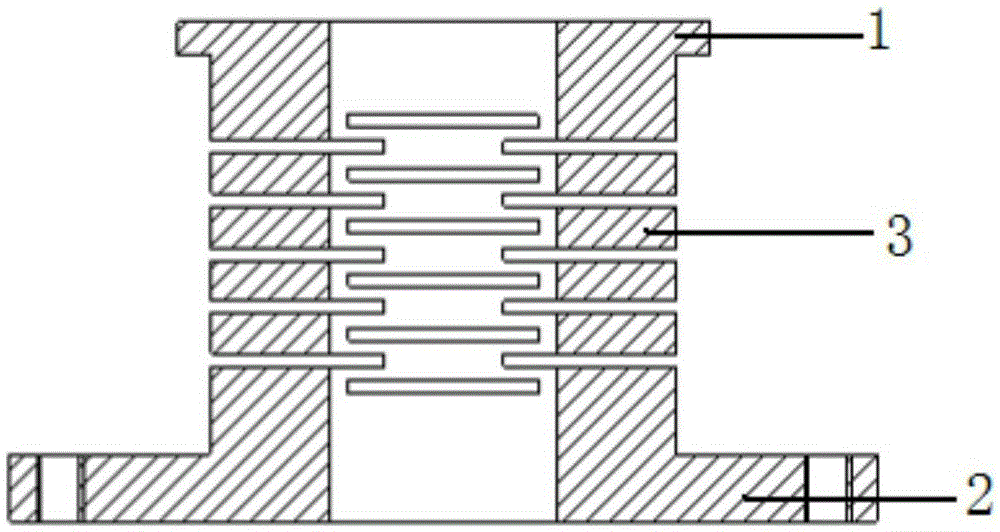

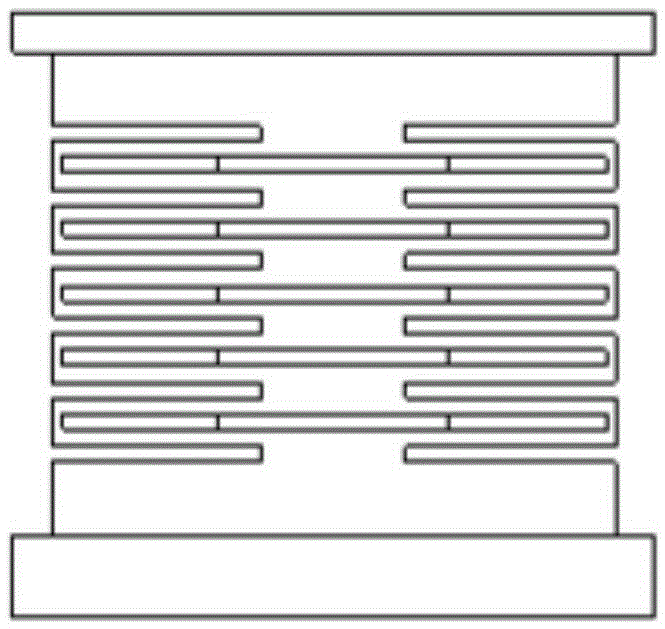

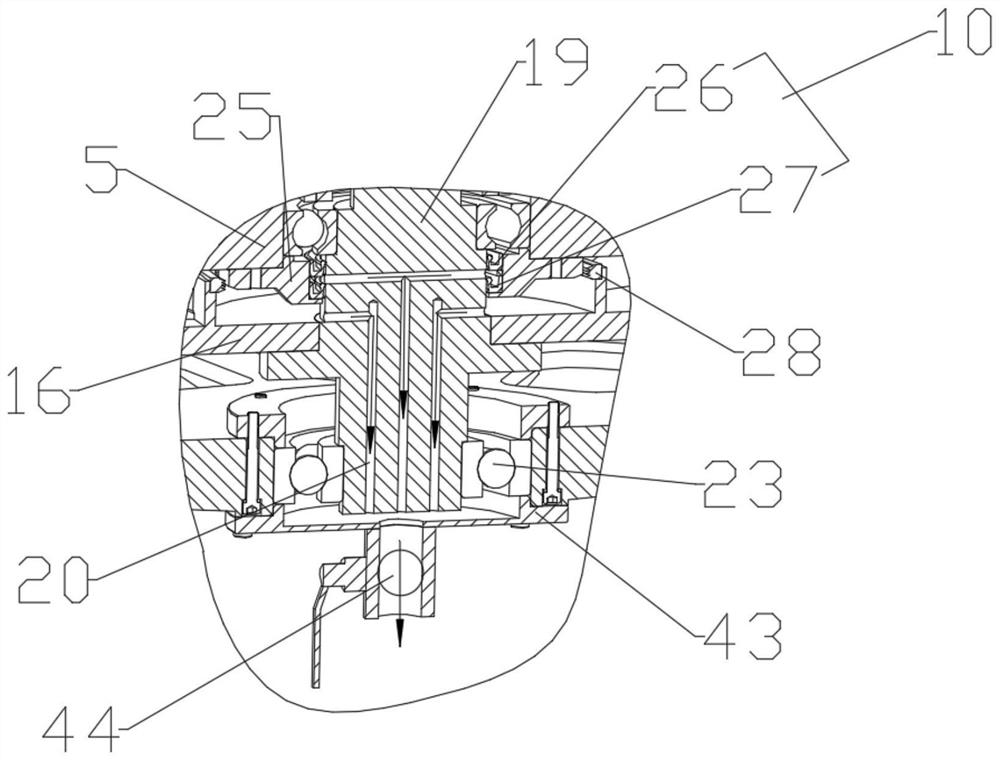

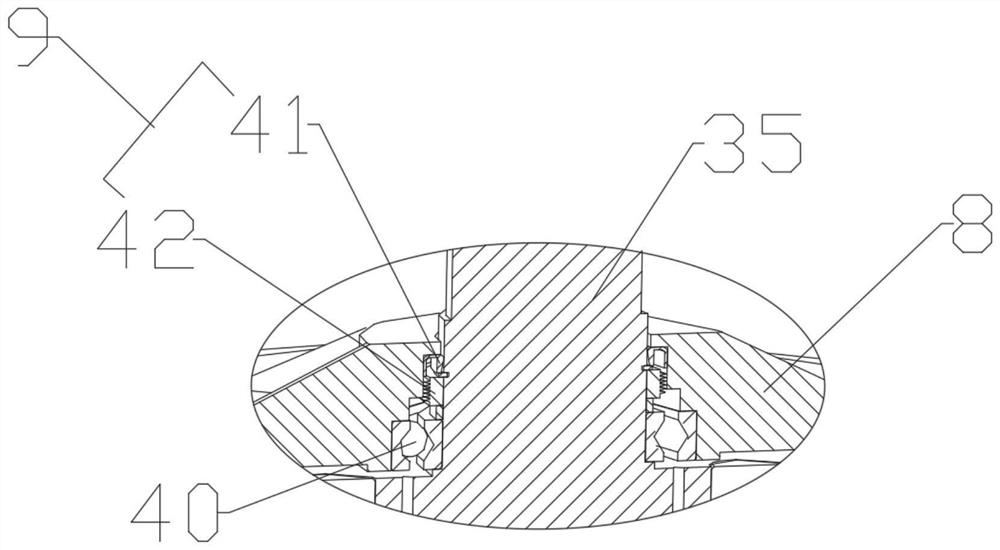

The invention relates to an overall composite mechanical spiral type bulging device for a car drive axle. The bulging device comprises a bulging inner die, a bulging outer die and two thrust hydraulic cylinders, wherein the bulging inner die comprises an upper die block and a lower die block, and an auxiliary pressure device is arranged between the upper die block and the lower die block. Two ends of the upper die block and the lower die block are respectively hinged with the piston rods of the two thrust hydraulic cylinders through link mechanisms. The link mechanisms comprise hinge mounts, and the hinge mounts are hinged with the upper die block and the lower die block through connecting rods. A spin screw mechanism is arranged between the two hinge mounts and comprises a screw, one end of the screw is installed on one hinge mount, and the other end of the screw is installed a spiral base arranged on the other hinge mount. The screw and the spiral base mutually rotate under the action of force, and the length of the screw is automatically regulated. The bulging outer die comprises a support mechanism positioned on the transitional surface of an axle shell pipa bag. The piston rods of the two thrust hydraulic cylinders are oppositely arranged, and a quick-detached connecting structure is arranged on the piston rod of one thrust hydraulic cylinder.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

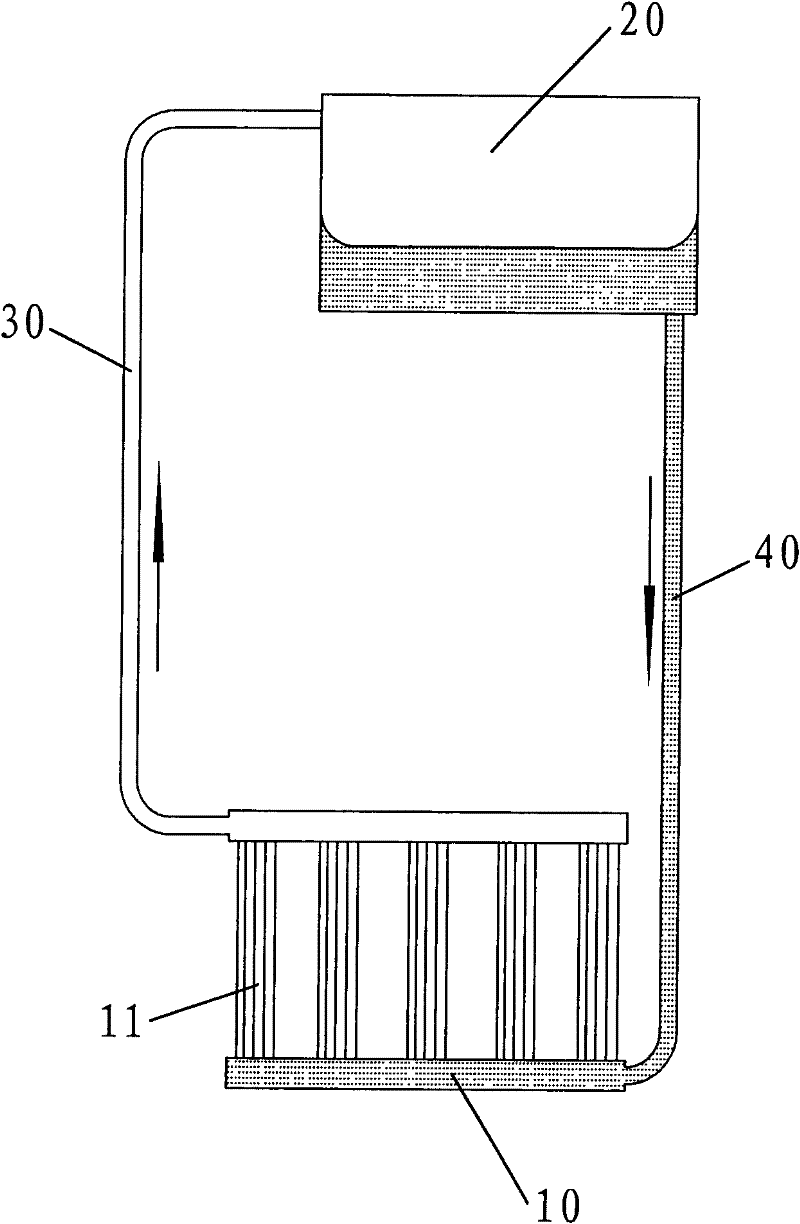

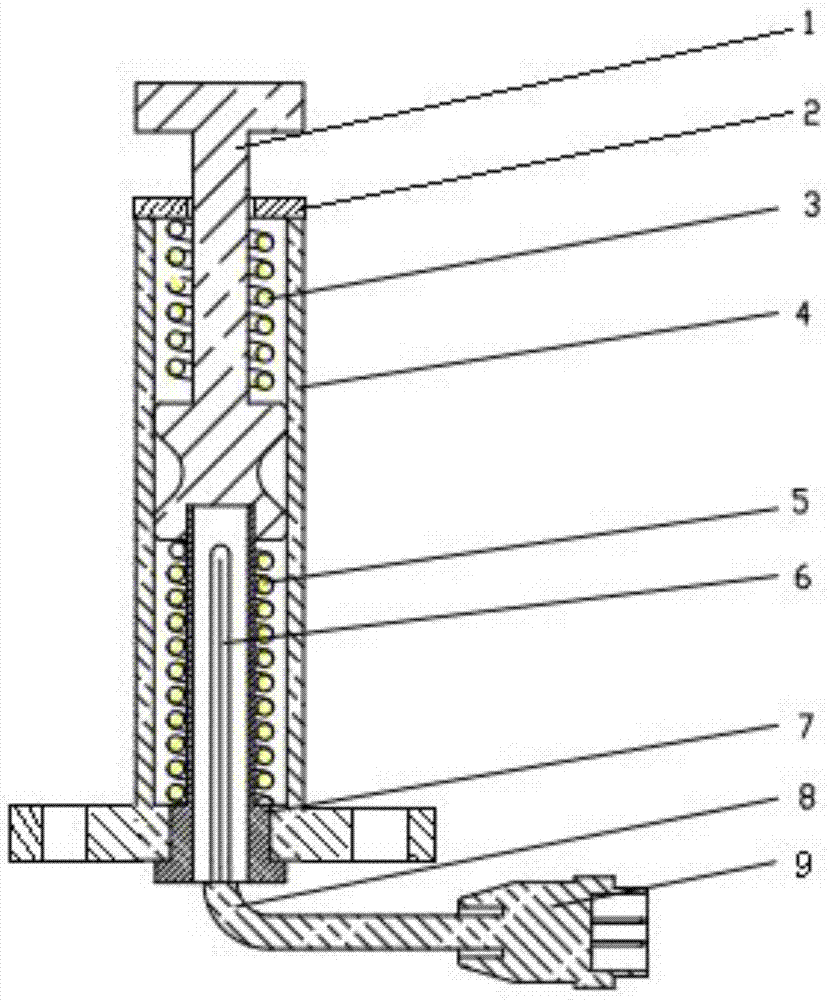

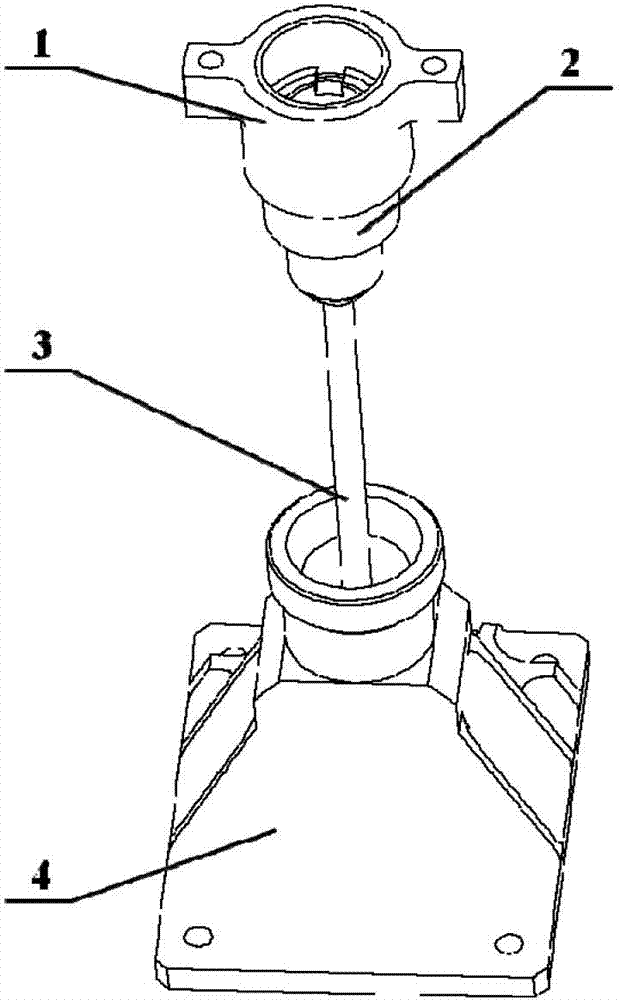

Loop gravity-assisted heat pipe heat transfer device

InactiveCN102538524AMeet the requirements for installation and useFully contactedIndirect heat exchangersGravity assistEngineering

The invention relates to a loop gravity-assisted heat pipe heat transfer device which mainly comprises an evaporator, a condenser, a steam pipe and a liquid pipe, wherein the evaporator is pipe-shaped, the evaporator is sealed and is filled with a working medium, an inlet of the steam pipe slightly extends into the top of the evaporator, and an outlet of the liquid pipe passes through the top of the evaporator and extends to the bottom of the evaporator; and an outlet of the steam pipe is communicated with the upper part of the condenser, and an inlet of the liquid pipe is communicated with the lower part of the condenser. The loop gravity-assisted heat pipe heat transfer device disclosed by the invention has excellent heat transfer performance and application expandability, can avoid installation difficulty, meets heat transfer requirements of vacuum tube heat collectors with any sizes and has the advantages of reliable structure and manufacturing process and lower cost.

Owner:北京芯铠电子散热技术有限责任公司

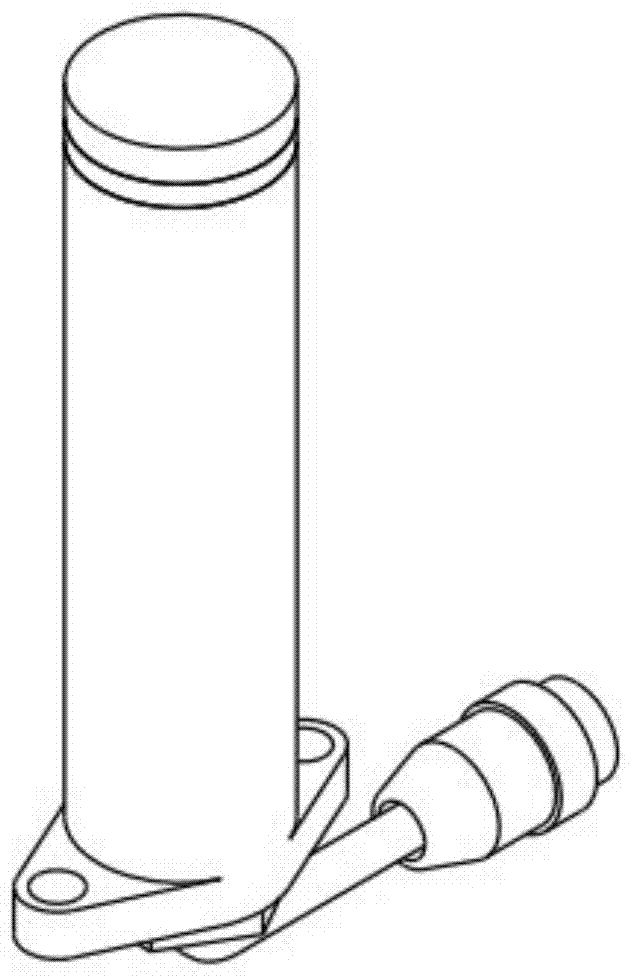

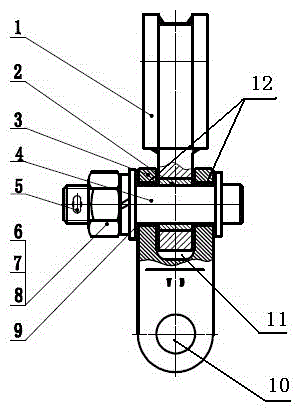

Low impact unlocking device based on shape memory alloy spring, and application method thereof

ActiveCN103253384AImprove connection stiffnessRelease shock load is smallCosmonautic component separationSpacecraftPayload

The invention discloses a low impact unlocking device based on a shape memory alloy spring and mainly applied to spacecraft. A main structure of the low impact unlocking device can be mounted an effective load to be unlocked and can be used with bolts to connect a spacecraft body with the load. When on-orbit unlocking is needed, the mechanism can be unlocked by heating the shape memory alloy spring of the low impact unlocking device, restraint between the bolts and nuts is unlocked by moving the mechanism, the bolts are separated from the nuts under the action of force, and accordingly two parts are unlocked. The low impact unlocking device has the advantages that such problems that an initiating explosive device widely on spacecraft models is high in impact and nonuniform in launching state and test state are solved; the device is reusable, lightweight, small and the like; and reliability, applicability and economy of the device are guaranteed.

Owner:SHANGHAI SATELLITE ENG INST

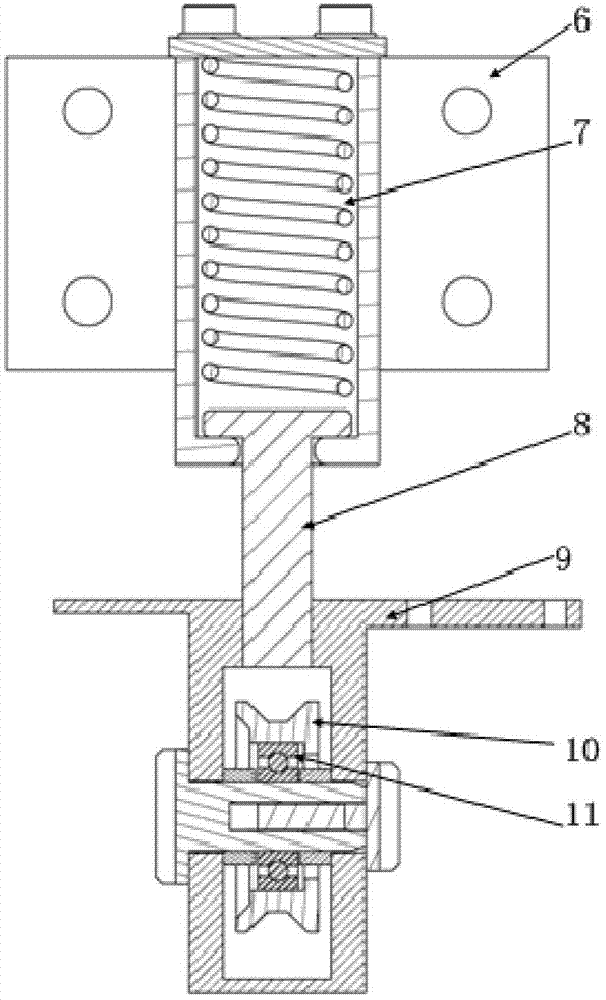

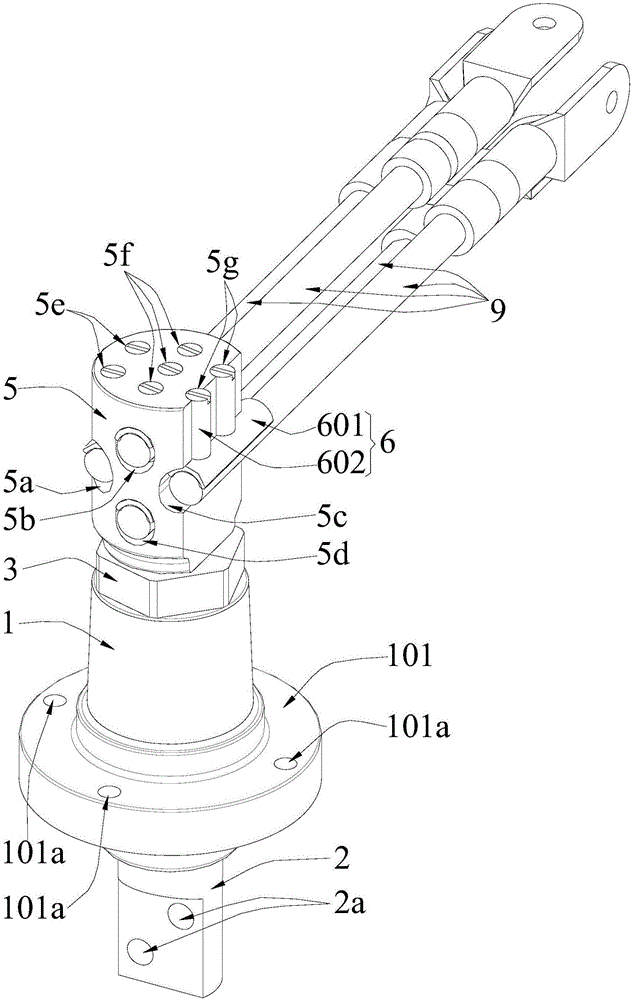

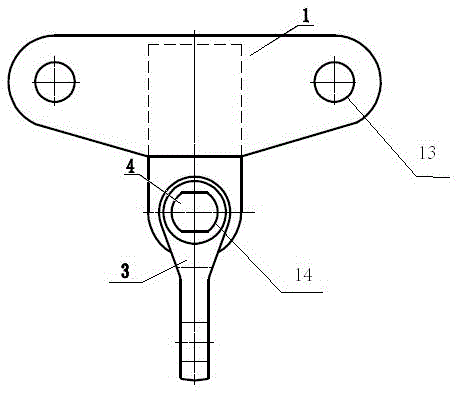

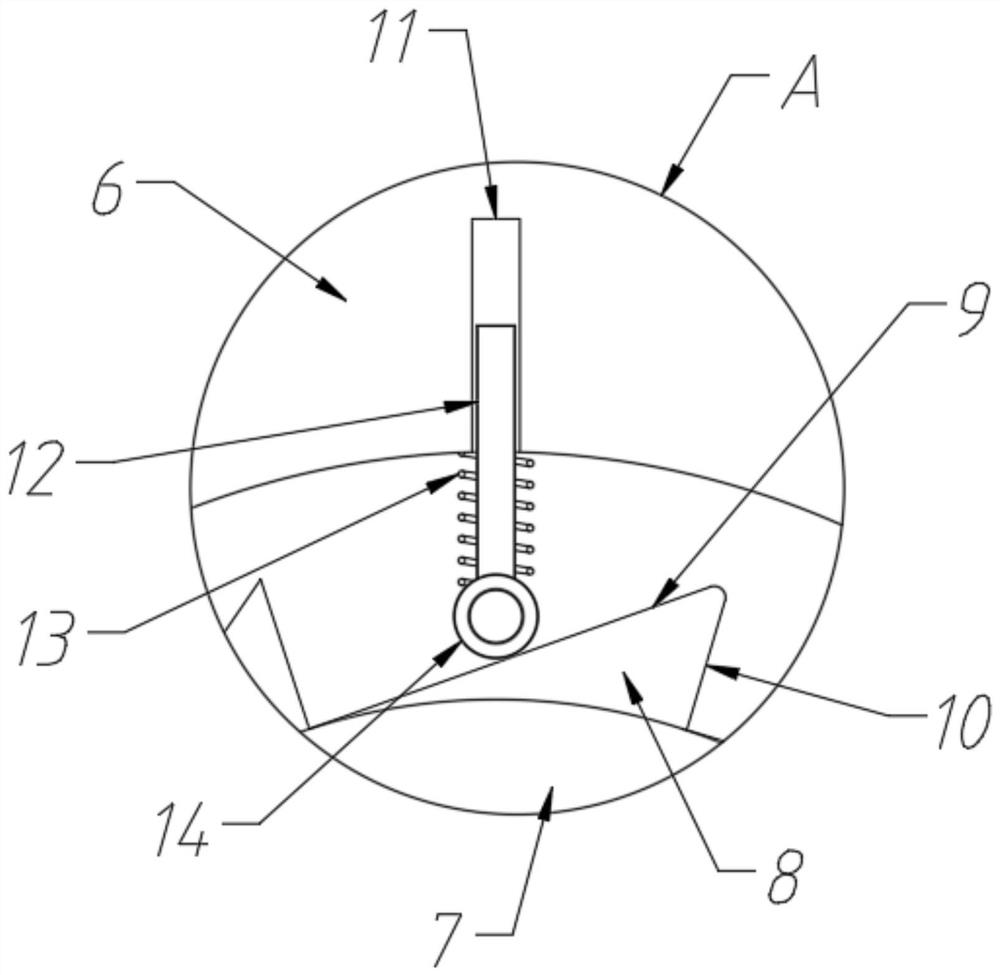

On-track monitoring device for tension of spacecraft rope

ActiveCN103245451AMeet the use requirements of tension monitoringSimple interfaceTension measurementEngineeringMechanical engineering

The invention discloses an on-track monitoring device for tension of a spacecraft rope. The device comprises an angular position sensor, a gear rack transmission assembly, a microswitch, an installation sleeve, a compression spring, a push rod and a roller assembly, wherein the rope rotates around the roller assembly; the roller assembly is tightly pressed by the compression spring through the push rod; the compression spring is mounted in the installation sleeve; a first end of the push rod slides inside the installation sleeve; an end part of a second end of the push rod is connected with the roller assembly; the roller assembly performs translational motion due to the change of the tension on the rope; the gear rack transmission assembly changes the translational motion of the roller assembly into rotation; the angular position sensor measures the rotation angle of the gear rack transmission assembly; and the microswitch triggers limit signals. According to the device, the problem that the tension of a rope part on the spacecraft requires to be monitored accurately is solved. At the same time, the device has the advantages of light mass, simple adjustment, small size, high security, low power consumption and the like, and the reliability and the applicability of on-track monitoring of rope tension are effectively guaranteed.

Owner:SHANGHAI SATELLITE ENG INST

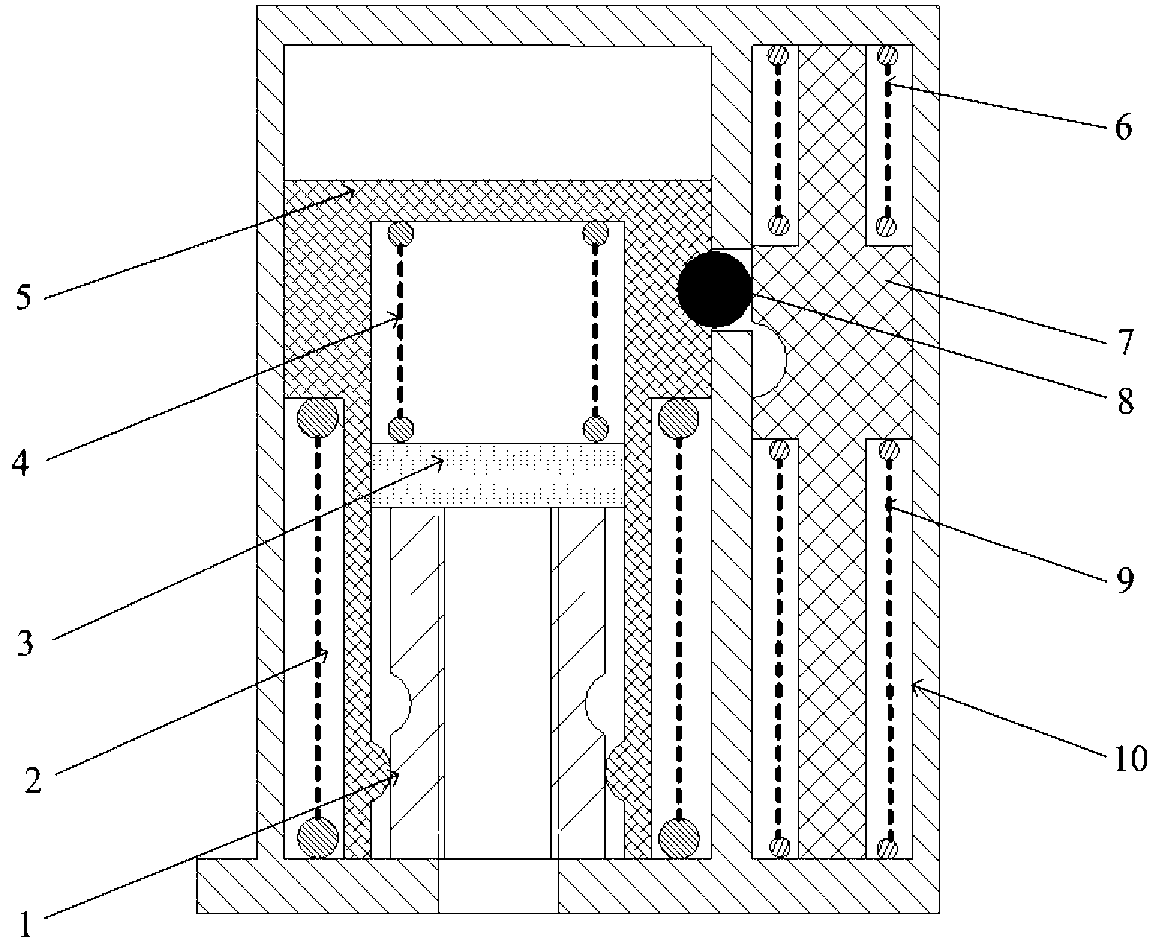

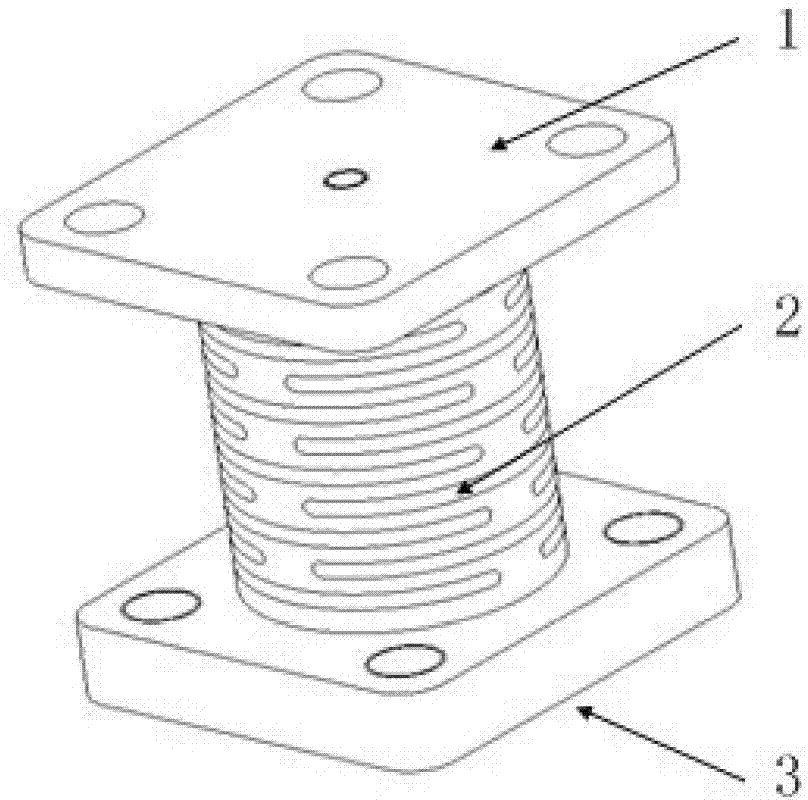

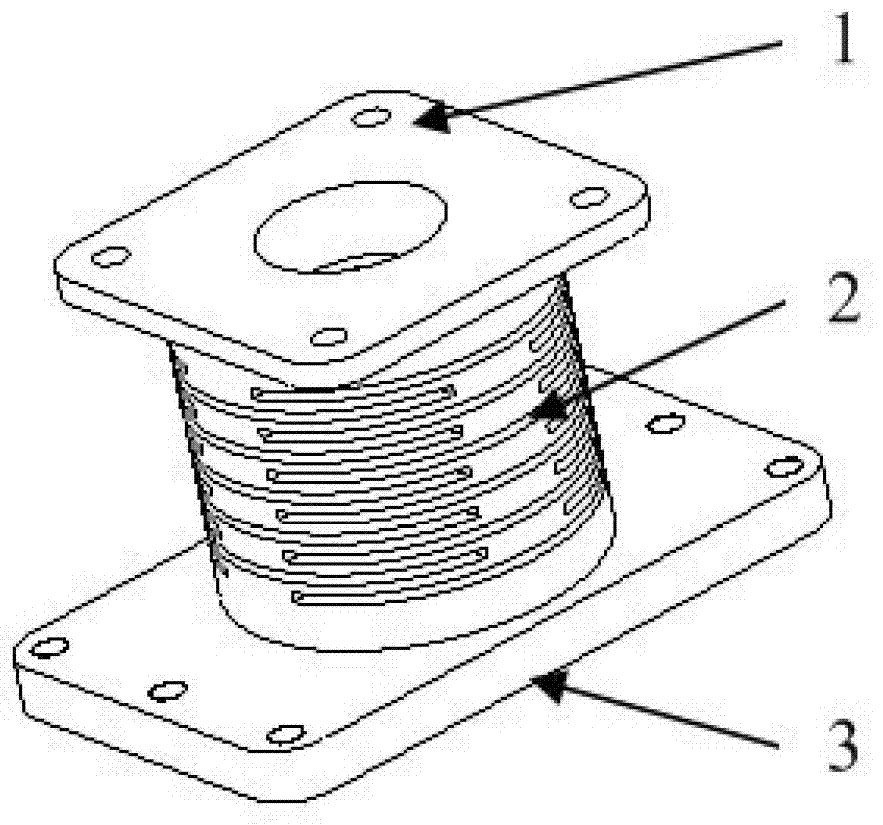

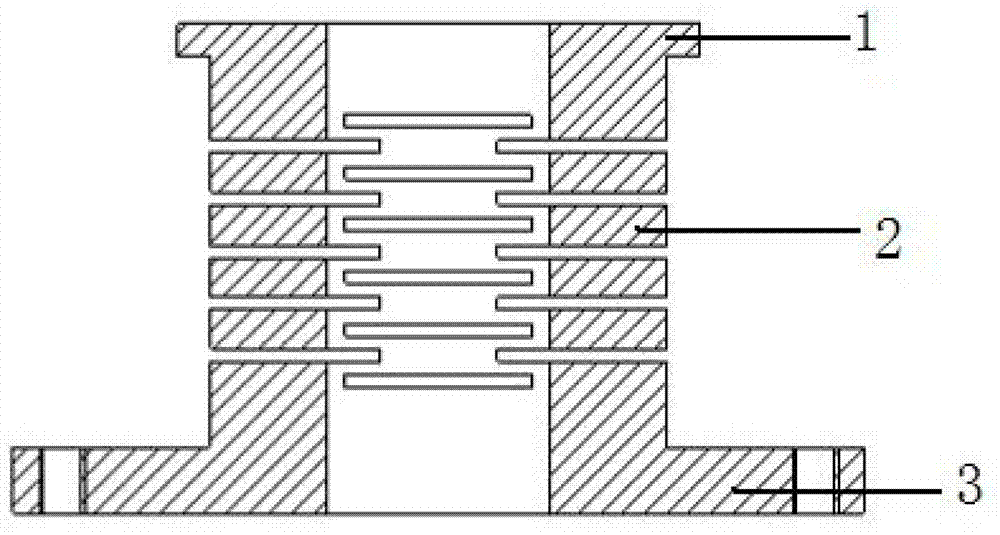

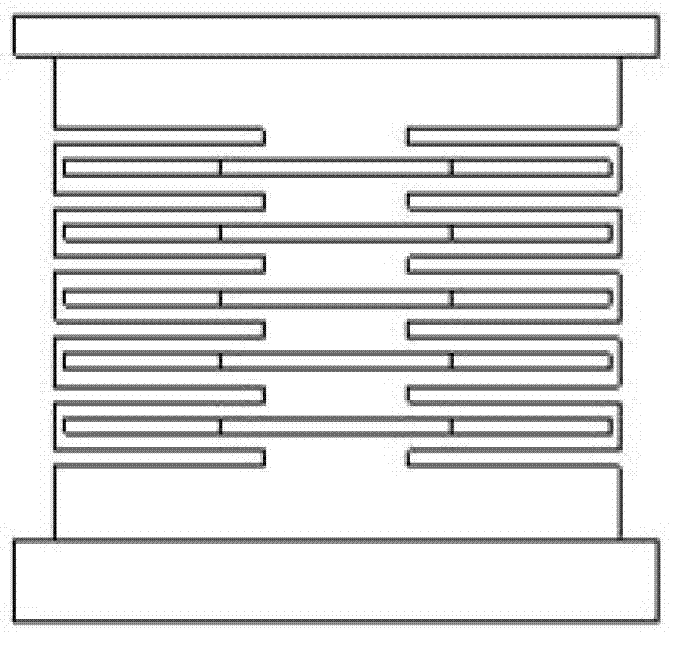

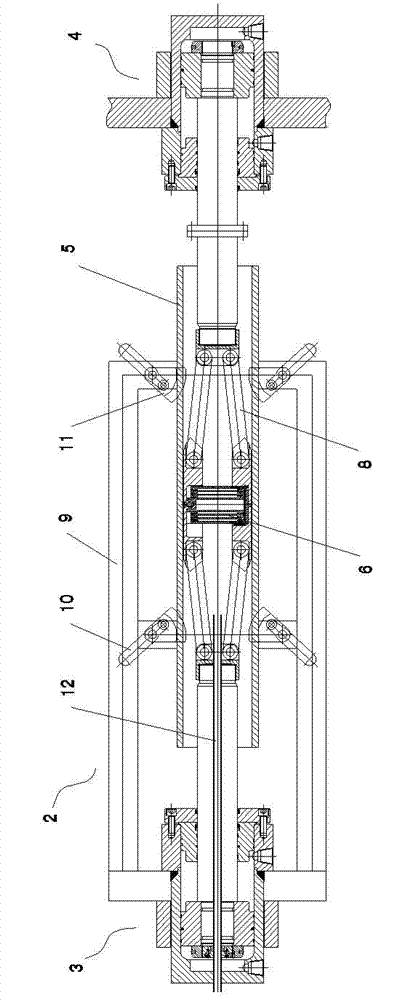

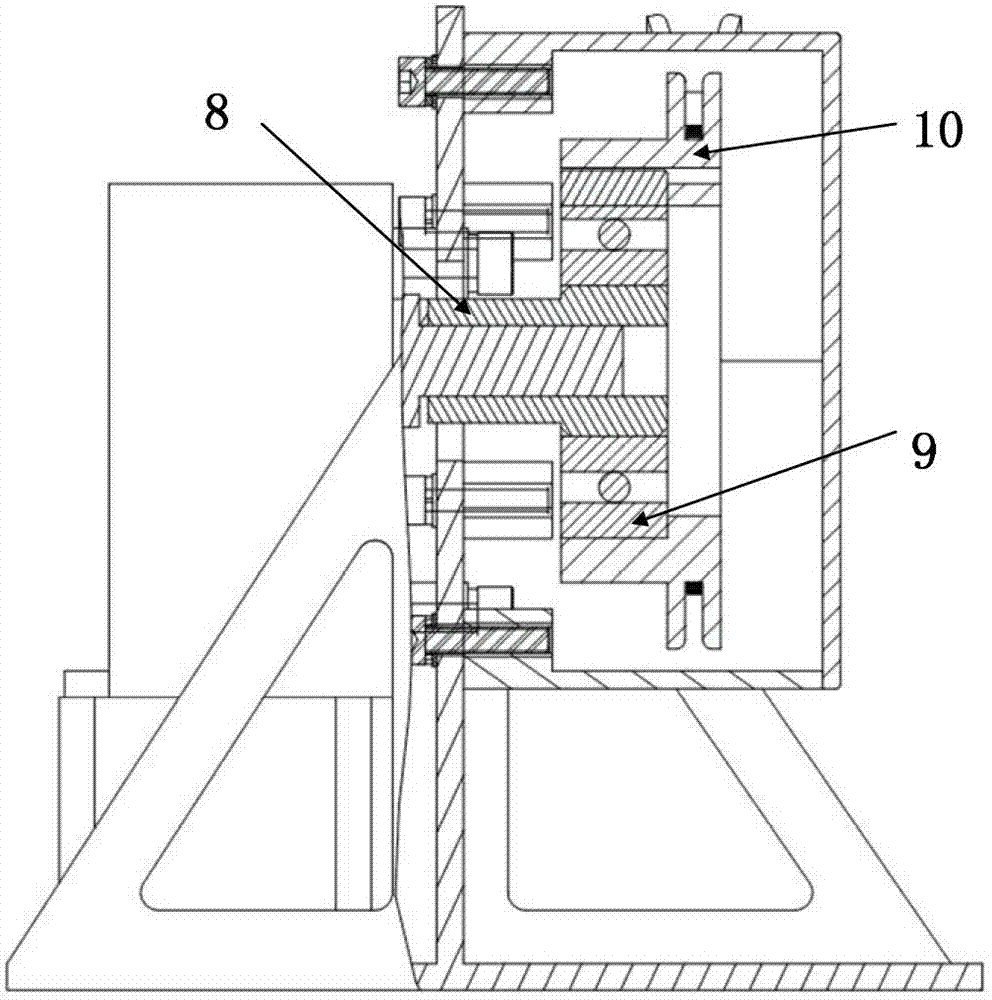

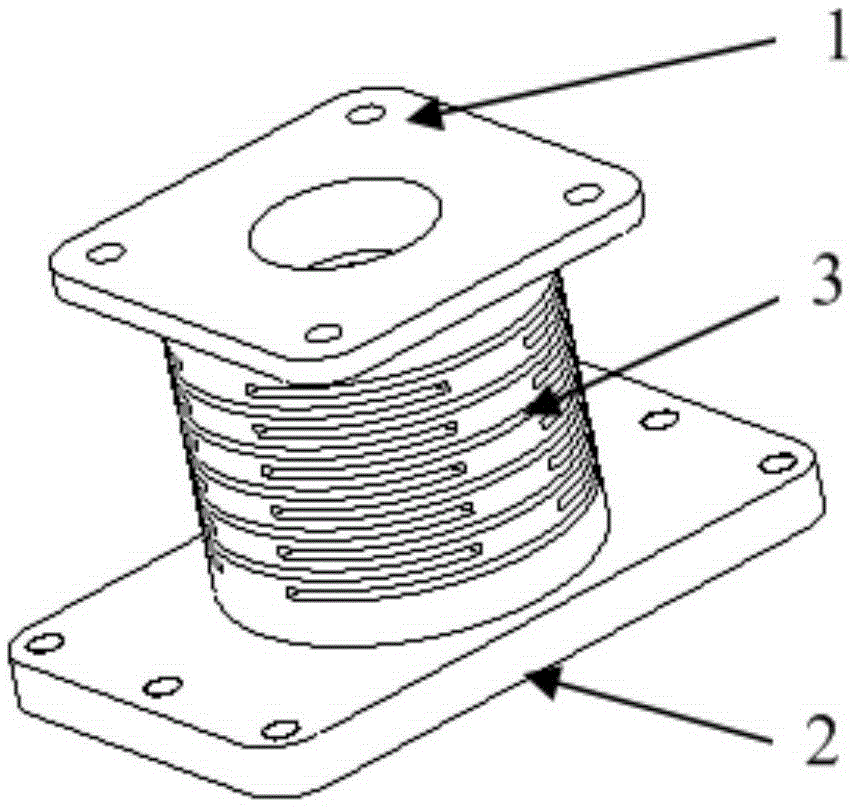

High-damping vibration isolator used for satellite sensitive load

ActiveCN103486183ASimple structureExcellent impact isolation performanceSpringsShock absorbersOrbitVibration isolation

The invention discloses a high-damping vibration isolator used for a satellite sensitive load. The high-damping vibration isolator used for the satellite sensitive load comprises an upper installation unit, a lower installation unit, a main vibration isolation unit and a high-damping unit, wherein the upper installation unit is connected with the satellite sensitive load; the lower installation unit is connected with a satellite body; the upper installation unit, the lower installation unit and the main vibration isolation unit integrally form a unified main vibration isolation structure; the main vibration isolation structure and the high-damping unit are connected in parallel. The high-damping vibration isolator used for the satellite sensitive load disclosed by the invention has the following technical characteristics: I, the installation of satellite sensitive load equipment is ensured; II, vibration transferred to the sensitive load by a satellite platform is isolated to ensure the normal operation and the working quality of the sensitive load; III, the vibration disturbance of the sensitive load is restrained; IV, an impact response brought by deblocking of a satellite initiating explosive device is rapidly damped. While the sensitive load is supported, the goal that the sensitive load can normally work in orbit reliably, safely and effectively is achieved.

Owner:SHANGHAI SATELLITE ENG INST

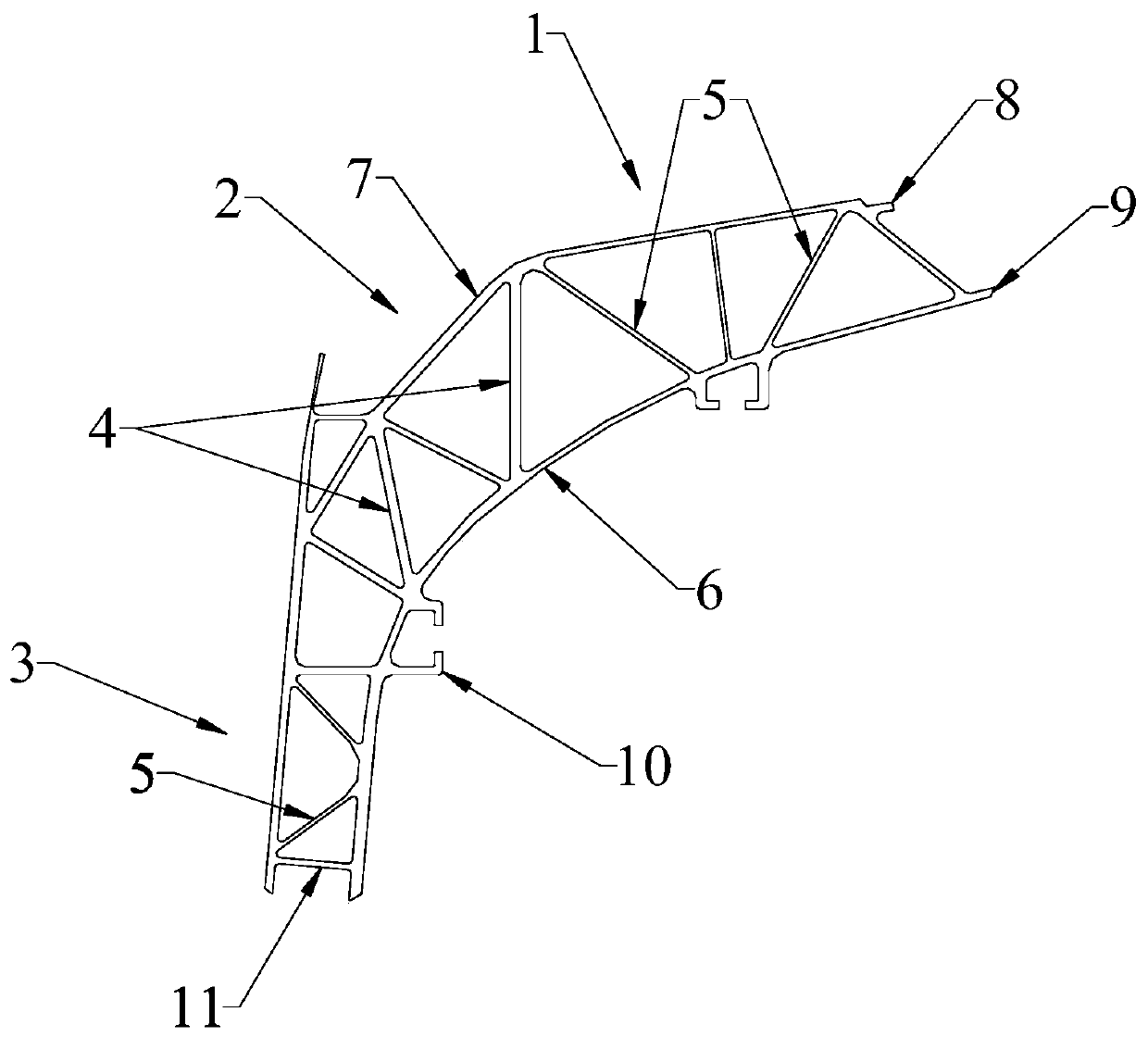

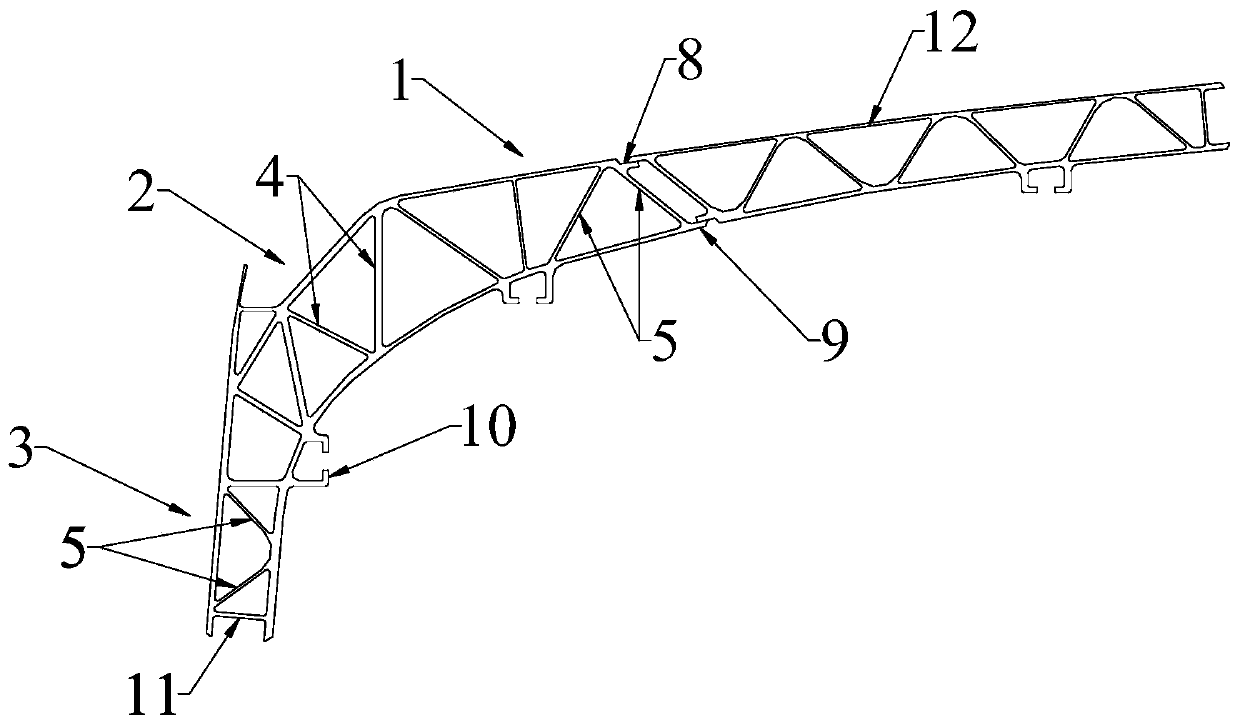

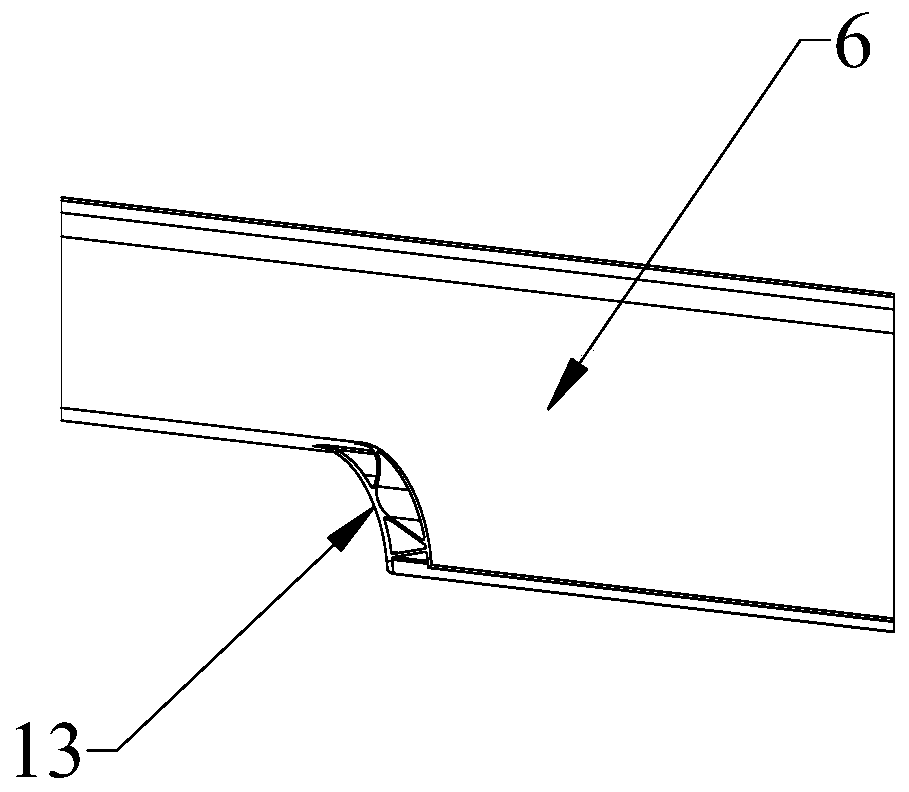

Roof side rail of vehicle

InactiveCN110126861AIncrease stiffnessOptimizationAxle-box lubricationRailway bodiesEngineeringHigh stress

The invention provides a roof side rail of a vehicle. The roof side rail of the vehicle comprises a roof rack connecting segment, transition segments and a side wall connection segment, the roof siderail is internally provided with a first supporting beam and a second supporting beam, and the first supporting beam is arranged on the transition segments; the second supporting beam is arranged on the roof rack connecting segment and / or the side wall connection segment; and the thickness of the first supporting beam is greater than the thickness of the second supporting beam. According to the roof side rail of the vehicle, the thickness of the first supporting beam is arranged to be greater than the thickness of the second supporting beam according to the principle that force borne by the first supporting beam between the transition segments is large and force borne by the second supporting beam of the side wall connection segment and / or the roof rack connecting segment is usually small,configuration of oblique reinforcements in the roof side rail of the vehicle is optimized, under the premise of effectively controlling the weight, the overall rigidity of the roof side rail of the vehicle is significantly improved, the rigidity of a high stress zone of a vehicle body is improved accordingly, and thus the problems that in the prior art, a roof side rail of the vehicle is excessively large in overall weight and inconvenient to machine are solved.

Owner:CRRC QINGDAO SIFANG CO LTD

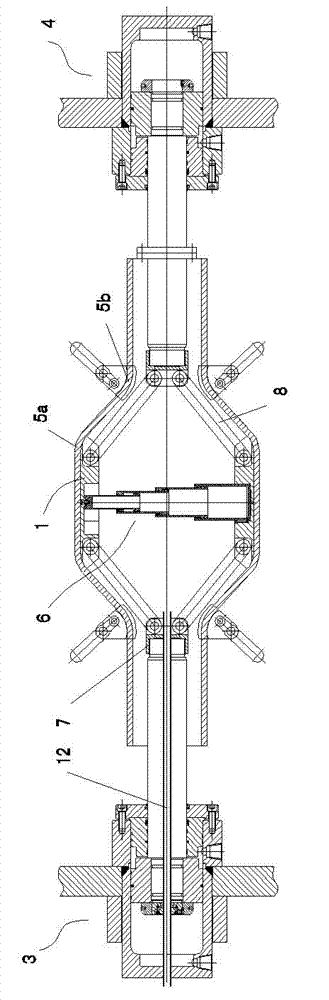

Novel vibration isolator used for satellite sensitive load

The invention discloses a novel vibration isolator used for a satellite sensitive load. The novel vibration isolator used for the satellite sensitive load comprises an upper installation unit, a lower installation unit and a main vibration isolation unit, wherein the upper installation unit, the lower installation unit and the main vibration isolation unit are of an integral structure. The novel vibration isolator used for the satellite sensitive load provided by the invention has the following technical characteristics: I, the installation of satellite sensitive load equipment is ensured; II, vibration transferred to the effective load by a satellite platform is isolated to ensure the normal operation of the effective load; III, the vibration disturbance of the effective load is isolated. While the sensitive load is supported, the goal that the sensitive load can normally work in orbit reliably, safely and effectively is achieved.

Owner:SHANGHAI SATELLITE ENG INST

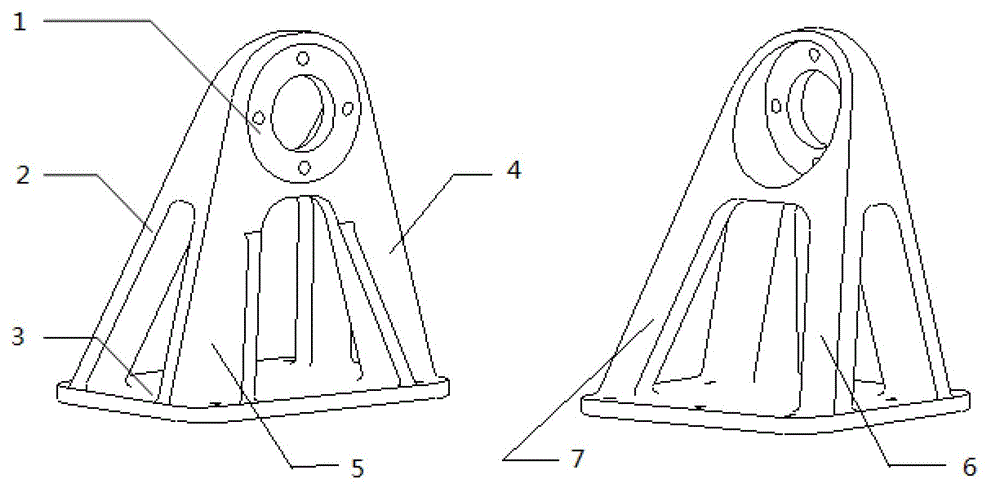

Novel flywheel support structure for spacecraft

ActiveCN102720801ASimple structureImprove mechanical propertiesVibration suppression adjustmentsMomentumFlywheel

The invention discloses a novel flywheel support structure for a spacecraft. The novel flywheel support structure for the spacecraft comprises a first mounting part, a main bearing structure, and a second mounting part. The flywheel support is designed according to the design concept of structural optimization, and allows for light weight of a flywheel while having better performances than the original design performances. The flywheel support provides moving parts, such as reaction flywheels, momentum wheels and torque compensation wheels, with stable mounting base, guarantees safety and reliability of crafts in satellite launching phase and orbiting respectively, can also satisfy heat transfer requirement and mechanical conditions for controlling subsystem flywheels (or reaction momentum wheels and torque compensation wheels) in operation, has the advantages of light weight, simple structure and low manufacturing cost and is highly universal.

Owner:SHANGHAI SATELLITE ENG INST

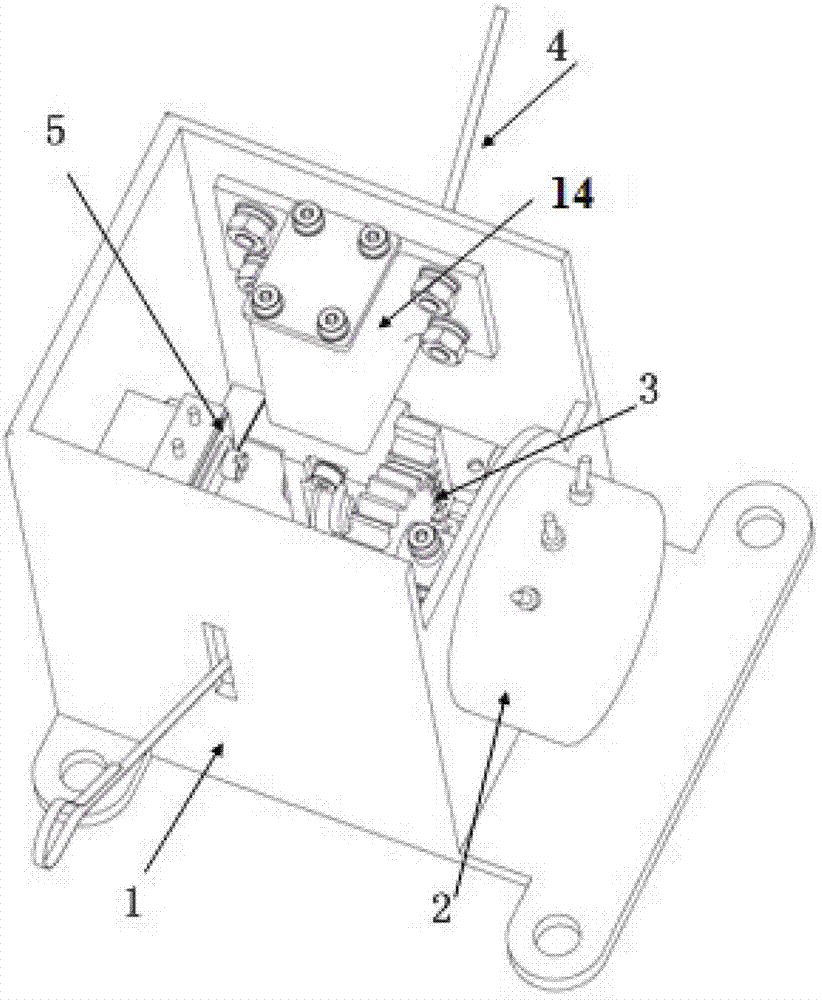

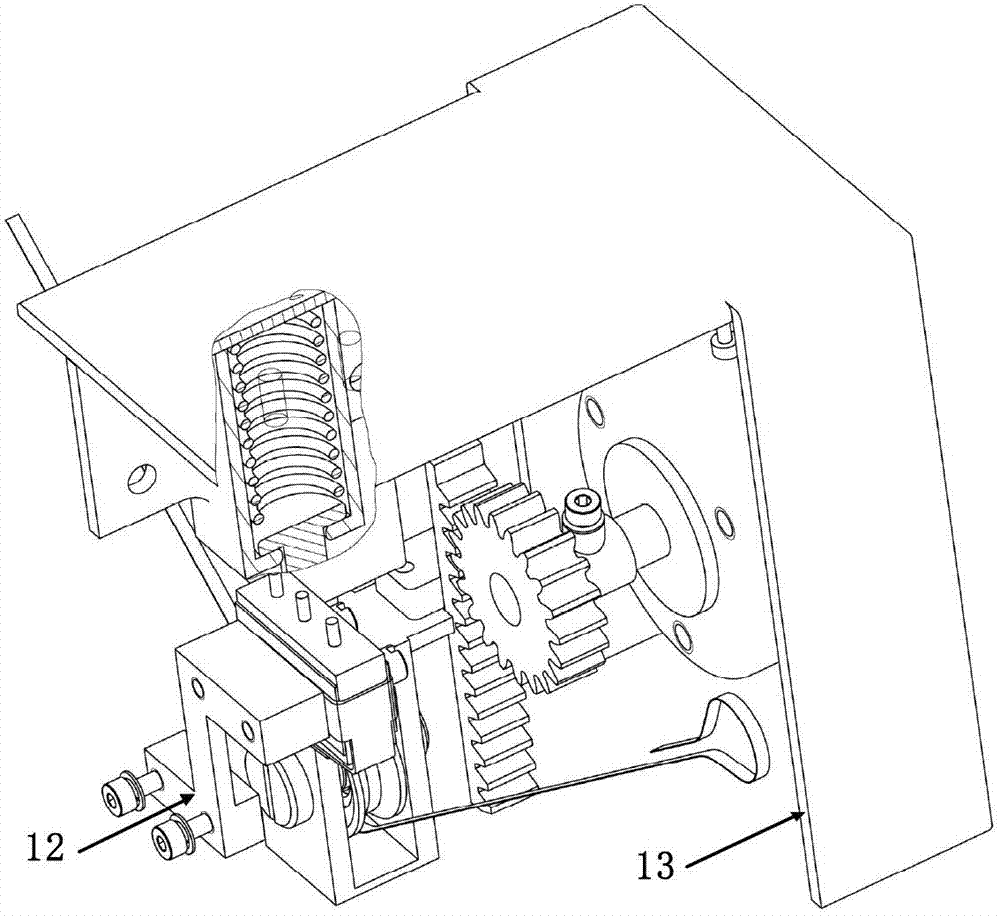

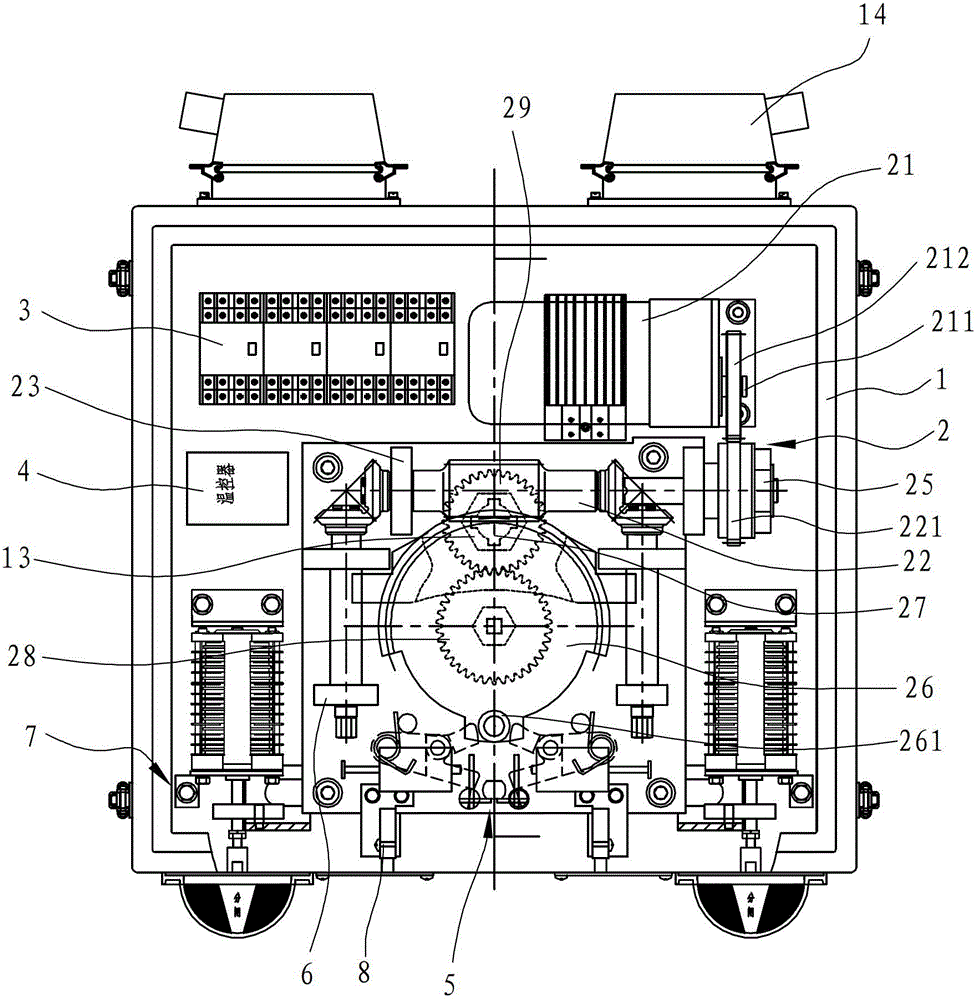

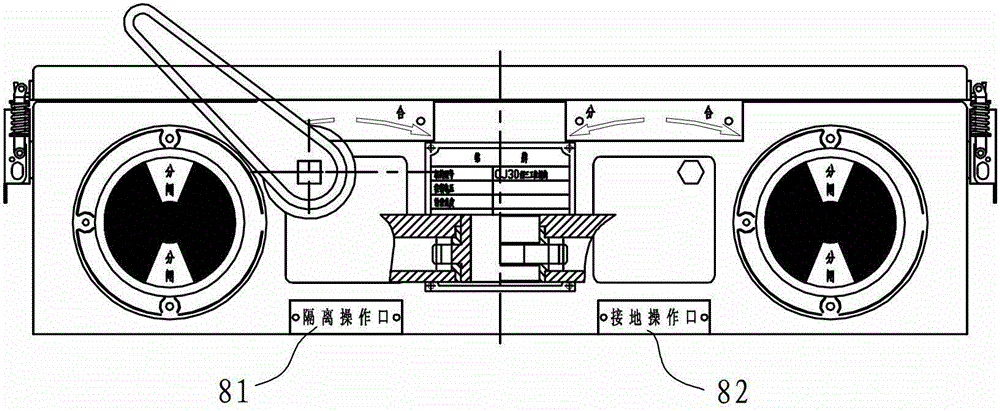

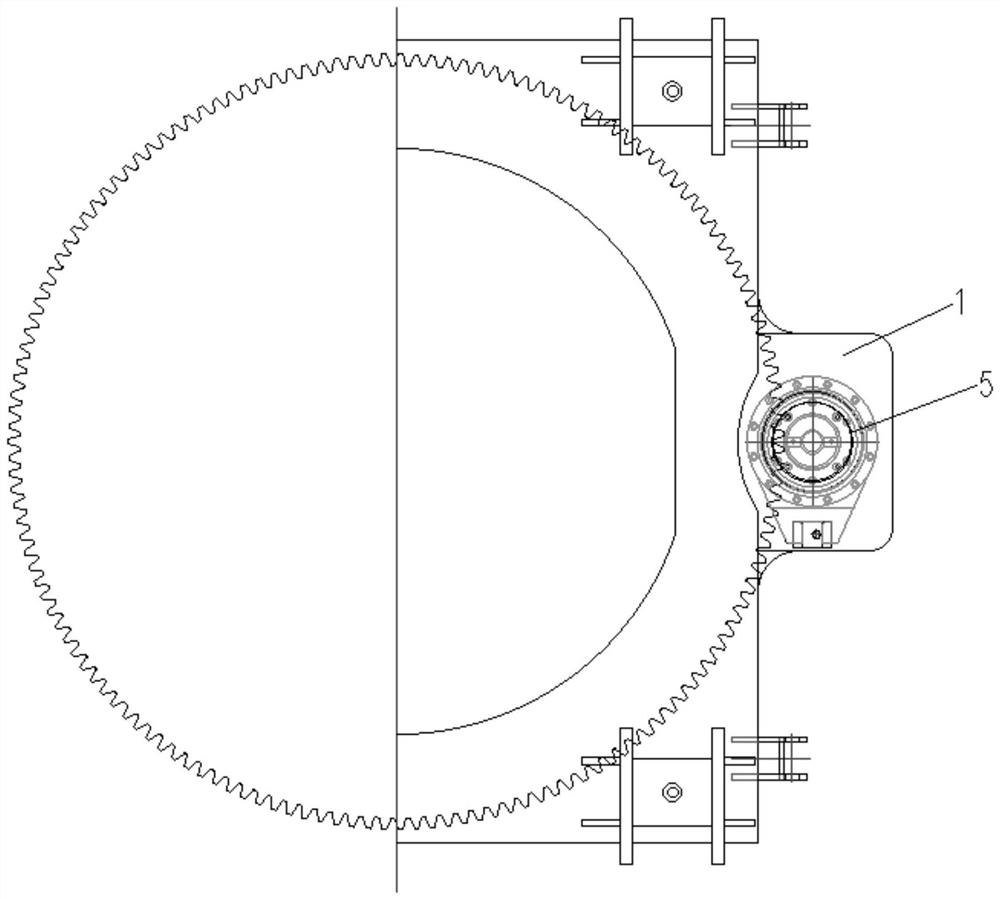

Single-motor three-station mechanism for switch

ActiveCN103165298BPlay a clutch roleGuaranteed coincidenceSwitch power arrangementsAir-break switch detailsGear wheelElectrical control

The invention discloses a single-motor three-station mechanism for a switch. The single-motor three-station mechanism comprises a frame, a driving device, a limit and separation mechanism, an electrical control device and an output shaft, wherein the driving device is mounted on the frame, the output shaft is connected with a switch shaft, and the driving device comprises a motor, a worm and worm gear pair, a clutch and a limit pin matched with the limit and separation mechanism. Manual shafts connected with a worm through a bevel gear pair are arranged on two sides of the worm respectively, an interlocking, indicating and auxiliary switch structure for interlocking manual operation and indicating on-off state is further arranged on the frame, the clutch is a torque clutch which is mounted at one end of the worm and abutted to a gear II mounted at the end of the worm, the gear II is engaged with a gear I mounted on a motor output shaft, a driving gear coaxial with the worm is engaged with a driven gear mounted on the output shaft, and the limit pin is fixed onto the end face of a worm gear.

Owner:YUYAO HUAYU ELECTRICAL APPLIANCE CO LTD

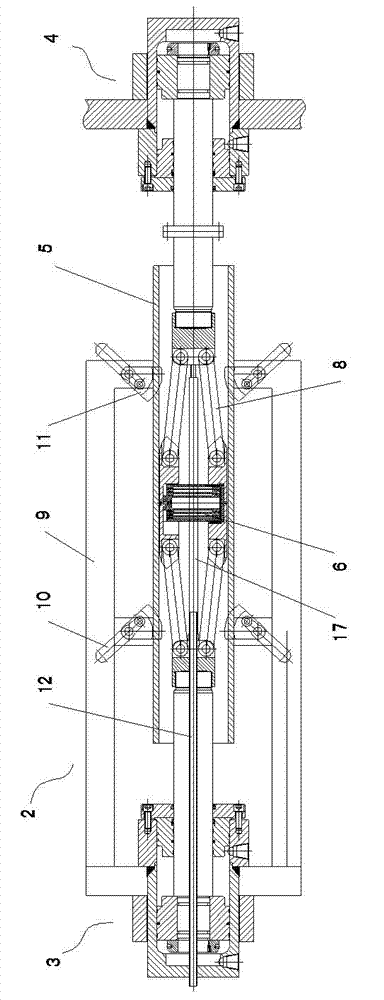

Overall composite mechanical push rod type or inner high-pressure bulging device for car drive axle

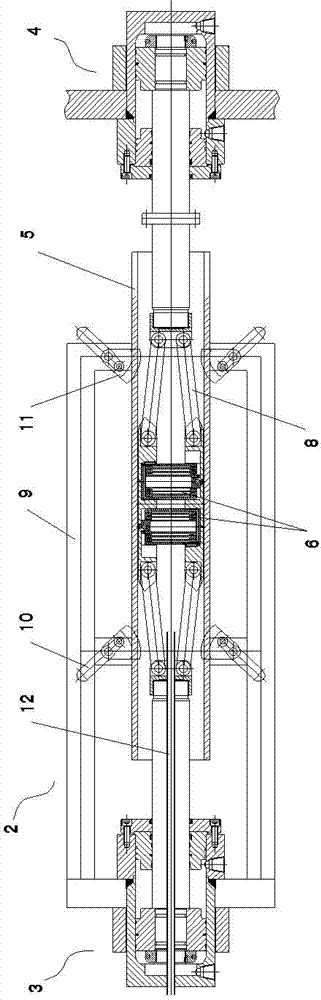

InactiveCN102886464AAccurately control the position of bulging deformationBulging achievedShaping toolsFluid-pressure actuatorsCar drivingTransaxle

The invention relates to an overall composite mechanical push rod type or inner high-pressure bulging device for a car drive axle. The bulging device comprises a bulging inner die, a bulging outer die and two thrust hydraulic cylinders, wherein the bulging inner die comprises an upper die block and a lower die block, and a multi-stage auxiliary hydraulic cylinder is arranged between the upper die block and the lower die block. Two ends of the upper die block and the lower die block are respectively connected with the two thrust hydraulic cylinders through link mechanisms. The multi-stage auxiliary hydraulic cylinder comprises an auxiliary piston rod and at least two stages of auxiliary hydraulic cylinder bodies which are stacked and sheathed together and adopt a telescopic structure, and the auxiliary piston rod is sheathed onto the innermost layer of auxiliary hydraulic cylinder body. Oil ports connected with a hydraulic source are arranged on a rodless chamber, a piston rod chamber and a grading oil chamber of the multi-stage auxiliary hydraulic cylinder. The bulging outer die comprises a support mechanism positioned on a transitional surface between the bulging deforming area and the un-deforming area of an axle shell pipa bag. The piston rods of the two thrust hydraulic cylinders are oppositely arranged, and the axes of the two piston rods are positioned on the same one straight line. Moreover, a quick-detached connecting structure is arranged on the piston rod of one thrust hydraulic cylinder.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

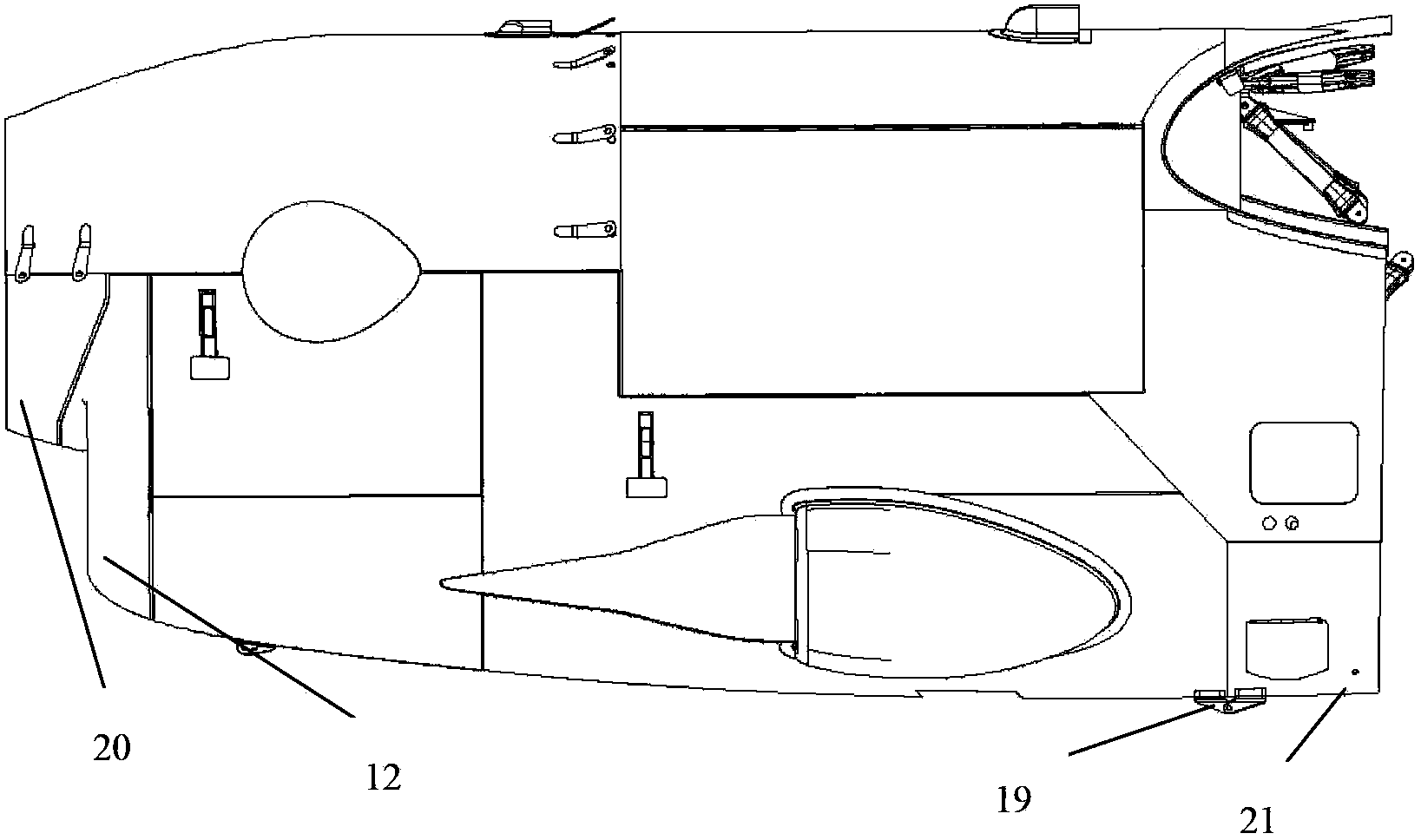

Aircraft engine compartment air inlet flue fairing

InactiveCN103523235AMeet the requirements for installation and useAvoid interferenceAircraft power plant componentsPower plant air intake arrangementsJoistAircraft manufacturing

The invention relates to the field of aircraft manufacturing, and provides an aircraft engine compartment air inlet flue fairing. The aircraft engine compartment air inlet flue fairing comprises a 3 frame, an air inlet flue upper cover plate, a sealing belt, a front sealing plate, a screen component, a 9 frame, an upper long joist, a 10 frame, a skin component, an oblique beam, an end frame, a rear portion lip, a lock component, an engine air inlet flue component, a slide oil air inlet flue component, a slide oil cooler fairing, an ice and snow separation channel component, a connector reinforcing piece and an attachment joint. The aircraft engine compartment air inlet flue fairing effectively solves the problems that the air inlet flue fairing interferes with a blade, ice zone flight icing is caused, an ice and snow separation channel is small in structural space, and the shape of slide oil cooler air inlet flue is complex and is difficult to form, and fully meets the installation and use requirements of a new aircraft engine.

Owner:HARBIN

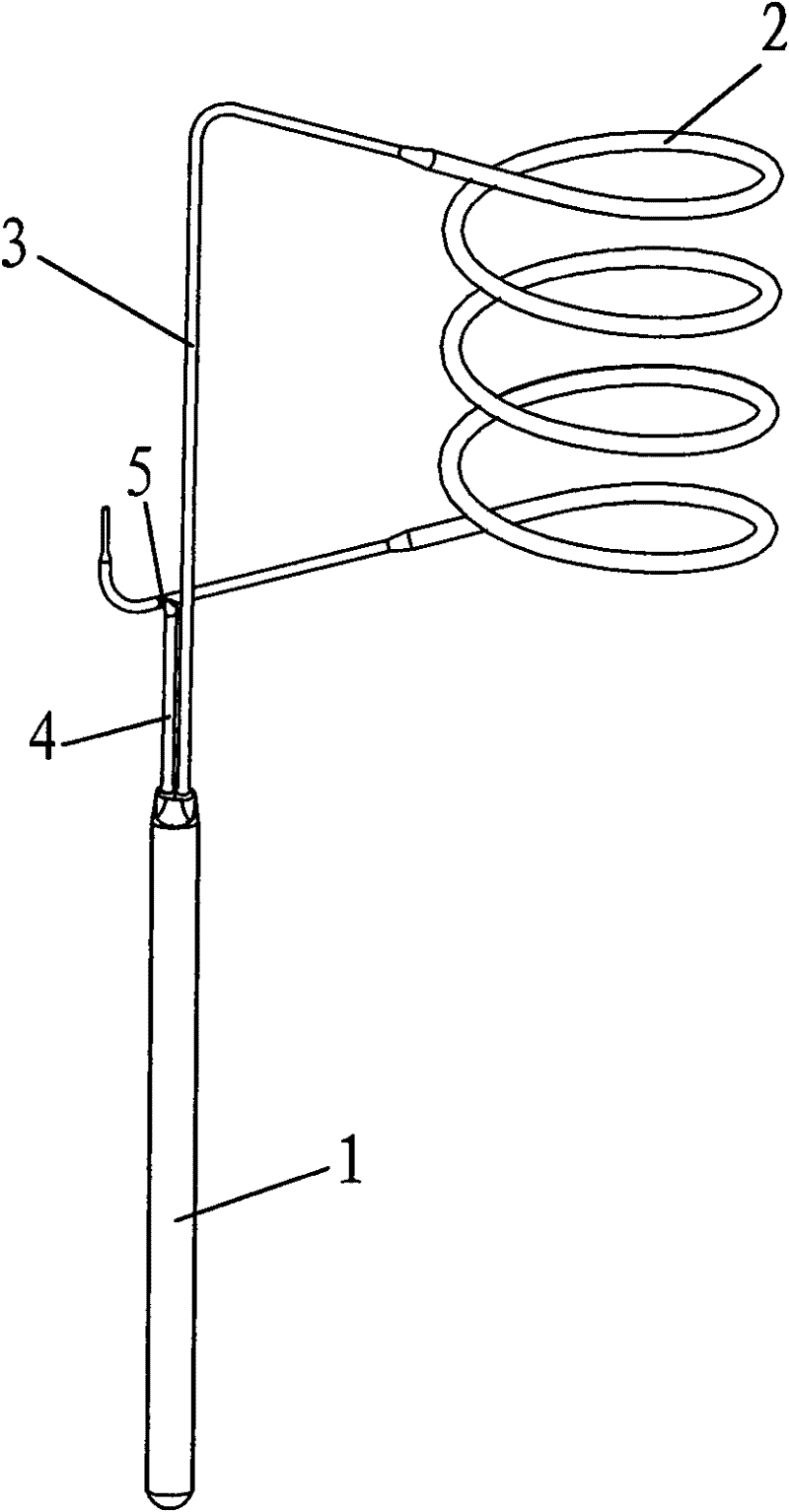

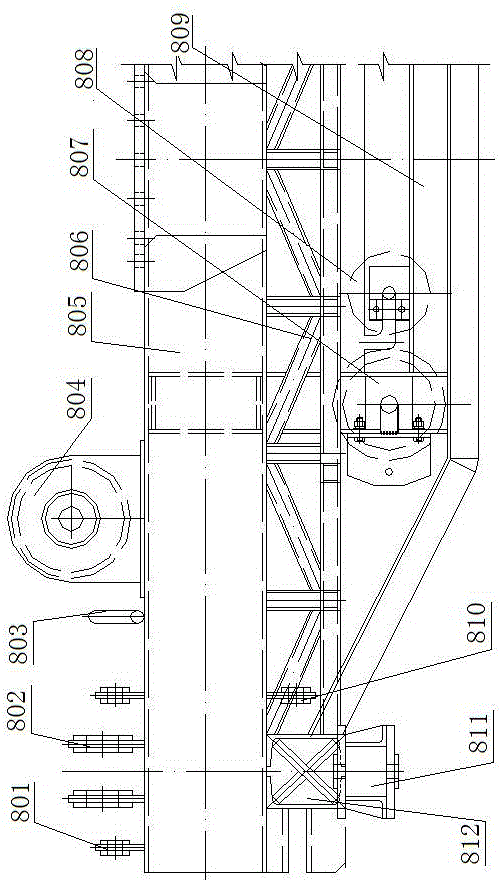

Straight acting device for spacecraft based on SMA (Shape Memory Alloy) spring and use method thereof

InactiveCN103696916AEasy to controlMeet the requirements for installation and useSpring motorMachines/enginesElectricityElectrical resistance and conductance

The invention discloses a straight acting device for a spacecraft based on an SMA (Shape Memory Alloy) spring and a use method thereof. The straight acting device for the spacecraft based on the SMA spring comprises a piston jacking rod, an upper end cover, a limiting spring, a sleeve, the SMA spring, a heater resistance wire, an electric heater, a soft outgoing line and an electric connector, wherein the sleeve is a piston cavity; a piston acting rod, the limiting spring, the SMA spring, the electric heater and the soft outgoing line are arranged in the sleeve from top to bottom; when the straight acting device does not work, the piston jacking rod is restrained in an initial position by the limiting spring, and the limiting spring and the SMA spring are balanced; when the straight acting device acts in orbit, any one of two heating wires in the heater is electrified through instruction, the SMA spring is heated, after the temperature reaches a phase-transition temperature, memory alloy is subjected to phase-transition, and the heat expanding type SMA spring stretches out and drives the piston jacking rod. The straight acting device for the spacecraft based on the SMA spring utilizes the advantage of easiness in controlling the action of the SMA spring and ensures the high reliability of a spacecraft mechanism.

Owner:SHANGHAI SATELLITE ENG INST

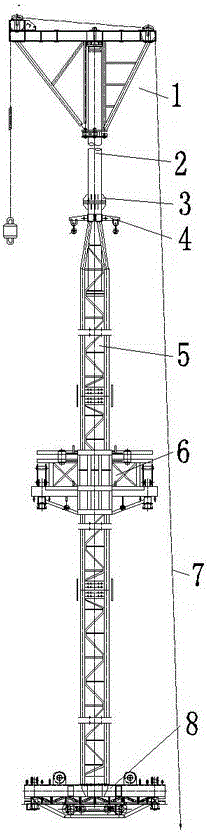

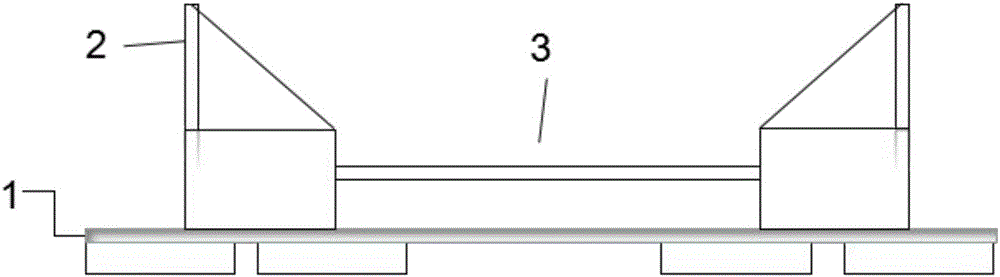

Self-elevating multifunctional climbing derrick mast

InactiveCN106245984APrevent job hoppingMeet the requirements for installation and useTowersCranesEngineeringTower crane

The invention provides a self-elevating multifunctional climbing derrick mast and belongs to the field of construction devices. The invention aims to provide a self-elevating multifunctional climbing derrick mast that may climb by means of the own structure thereof without an external auxiliary device. According to the self-elevating multifunctional climbing derrick, a mast derrick mast supporting beam is fixed to one end of the derrick mast. A derrick mast jacket sleeves the derrick mast. The other end of the derrick mast is fixed to one side of a jacket hoisting frame. The other side of the jacket hoisting frame is fixed to a rotating beam that passes through a rolling bearing to be inserted in a slot of a triangular bracket. The invention relates to a self-elevating multifunctional climbing derrick mast installation device that is capable of climbing without external power and multifunctional, and is used for setting up a latticeguyed high steel tower mast with excellent usability; and the problem that a large-tonnage crane, a tower crane, a helicopter and the like for modernized means may not be installed easily on existing domestic and overseas high guyed town masts is solved.

Owner:吉林安装集团股份有限公司

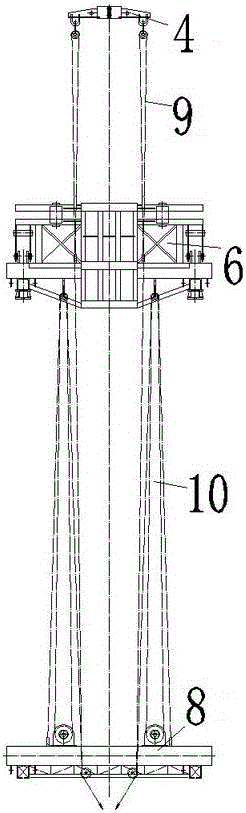

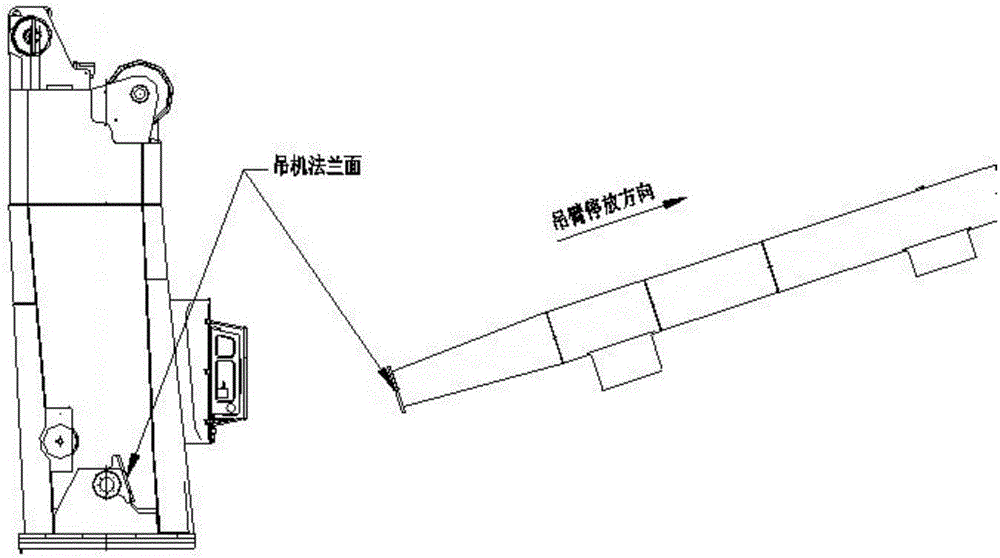

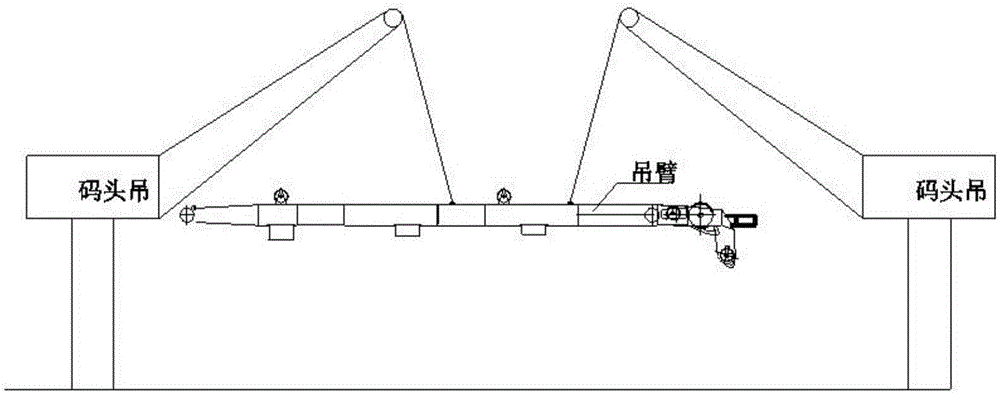

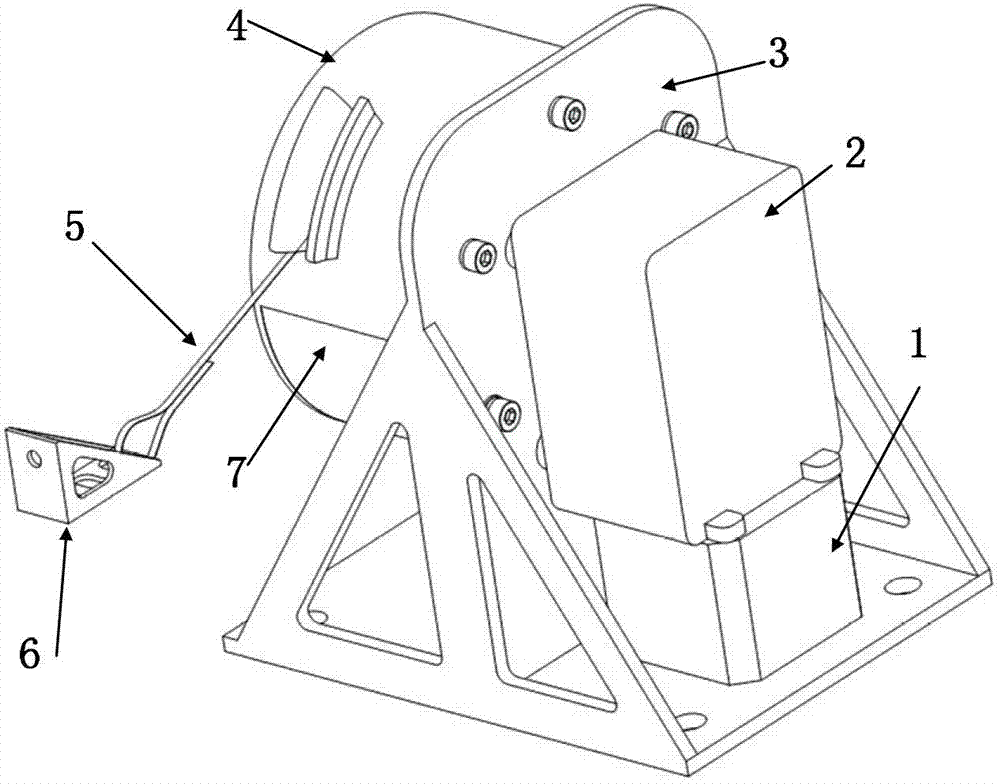

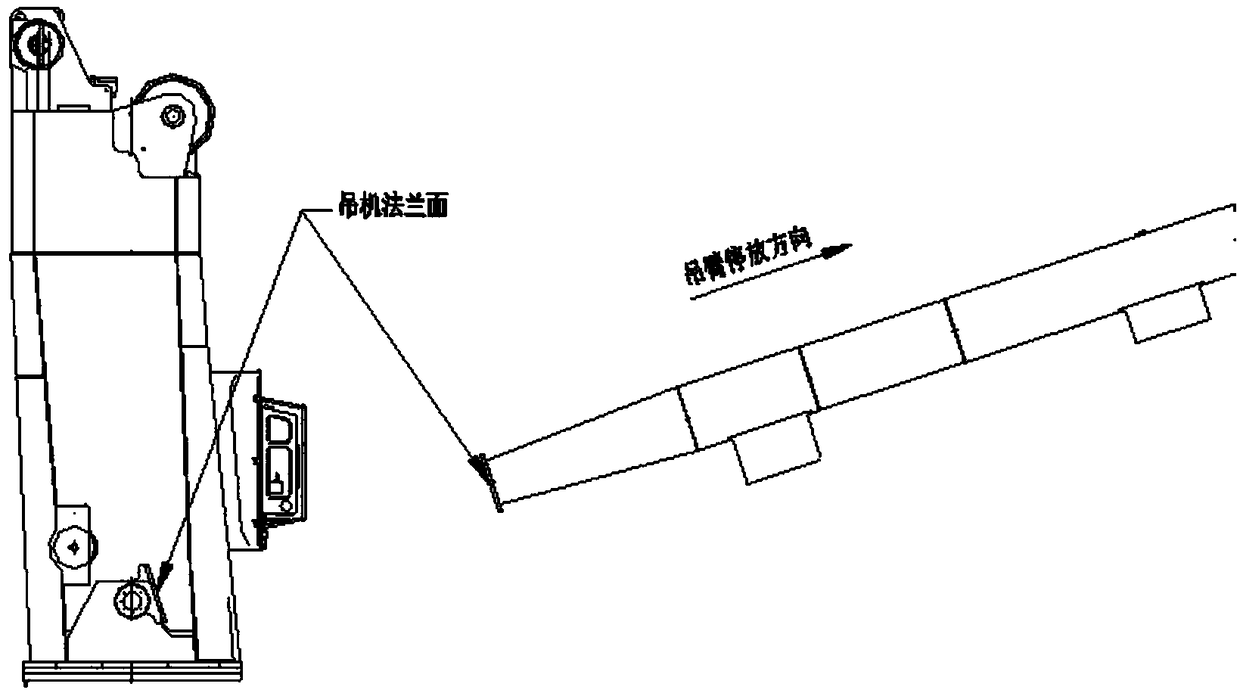

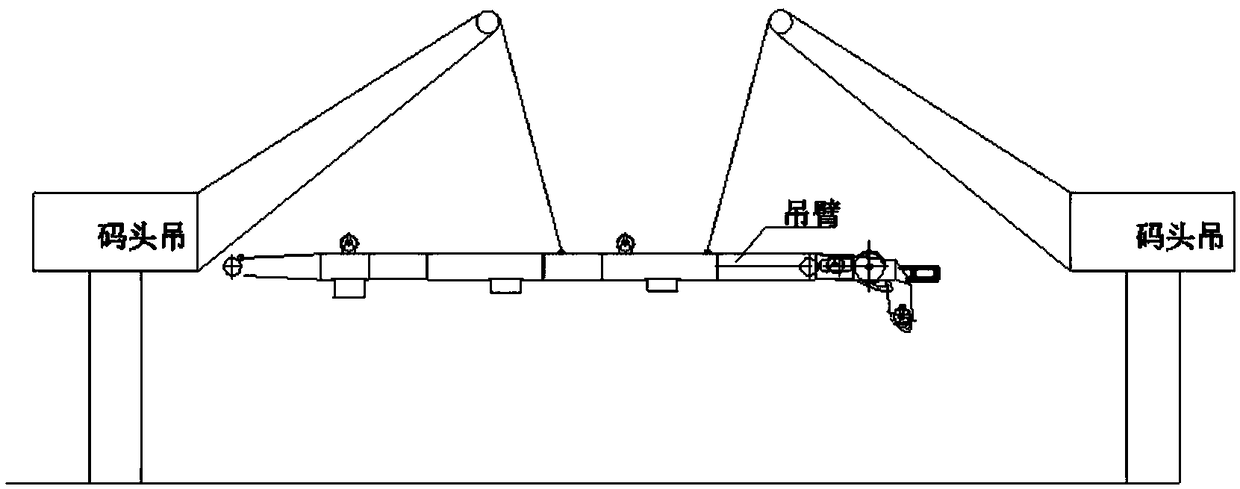

Heavy crane for ships and underwater installation technology

ActiveCN106564819AMeet the requirements for installation and useImprove installation accuracyCranesEngineeringTower

The invention discloses a heavy crane for ships and an underwater installation technology, the heavy crane for the ships comprises a support base, a tower body, a lifting arm, a steel wire rope and a hook, the lower end of the tower body is connected with the support base, the lifting arm is connected with the flange face of the tower body, one end of the steel wire rope is connected with the lifting arm, the other end of the steel wire rope is connected with the hook, and the support seat comprises a center seat, a plurality of adjustable auxiliary seat sets and an electric device. The underwater installation technology for the heavy crane for the ships is as follows: pre order preparation work, a tower body installation process, a lifting arm installation process and finishing work, the main installation steps are as follows: using a 200t engineering floating crane to lift the tower body about 110t for alignment connection with the support seat, using two quay cranes for combined lifting to lift the lifting arm about 65t, and aligning the flange face of the lifting arm for connection with the tower body. The heavy crane for the ships can shorten the shipbuilding cycle, and has the advantages of ingenious design, convenient installation and the like.

Owner:TAIZHOU SANFU SHIP ENG CO LTD

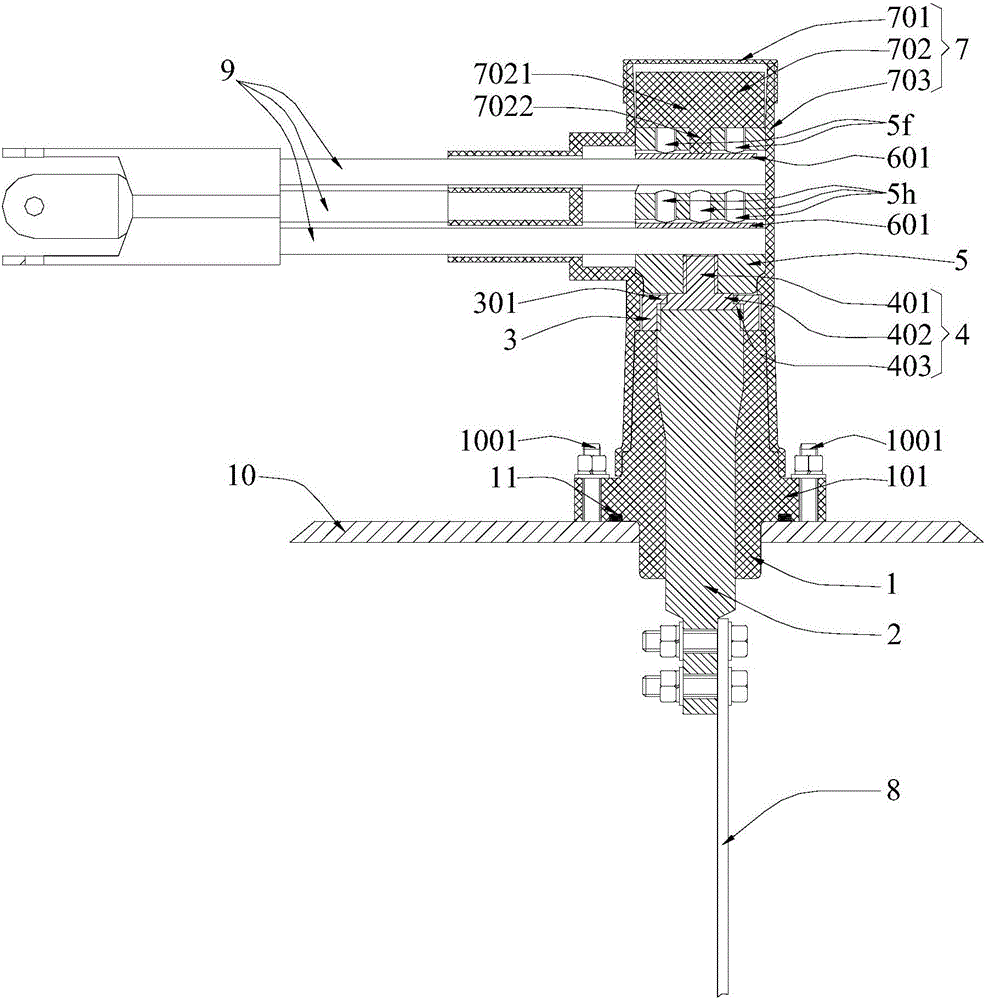

On-orbit frequency increasing mechanism for spacecraft flexible appendage

ActiveCN103241389ASatisfy the requirements of increasing frequencyWith expansion follow-up functionSpacecraft guiding apparatusCouplingEngineering

The invention discloses an on-orbit frequency increasing mechanism for a spacecraft flexible appendage. The on-orbit frequency increasing mechanism comprises a driving element, a speed reducing device, a support frame, a woven stay cord belt, a joint support, a transitional shaft section, a unidirectional bearing and a winding reel, wherein the driving element, the speed reducing device, the joint support, the transitional shaft section, the unidirectional bearing and the winding reel are respectively mounted on the support frame, the woven stay cord belt is wound on the winding reel, driving power of the driving element is transmitted to the winding reel via the speed reducing device, the transitional shaft section and the unidirectional bearing, the winding reel rotates to drive the woven stay cord belt to be tensioned and loosened, and an end portion of the woven stay cord belt is connected with the flexible appendage. By the on-orbit frequency increasing mechanism for the spacecraft flexible appendage, the problem that the spacecraft flexible appendage is too low in fundamental frequency or frequency is required to be improved for coupling of lower-order frequency and on-satellite disturbance source. Meanwhile, the on-orbit frequency increasing mechanism for the spacecraft flexible appendage has the advantages of light weight, simplicity in control, small size, capability of being unfolded along movement, low consumption and the like, and can effectively guarantee reliability and applicability of the spacecraft flexible appendage in the on-orbit frequency increasing mechanism.

Owner:SHANGHAI SATELLITE ENG INST

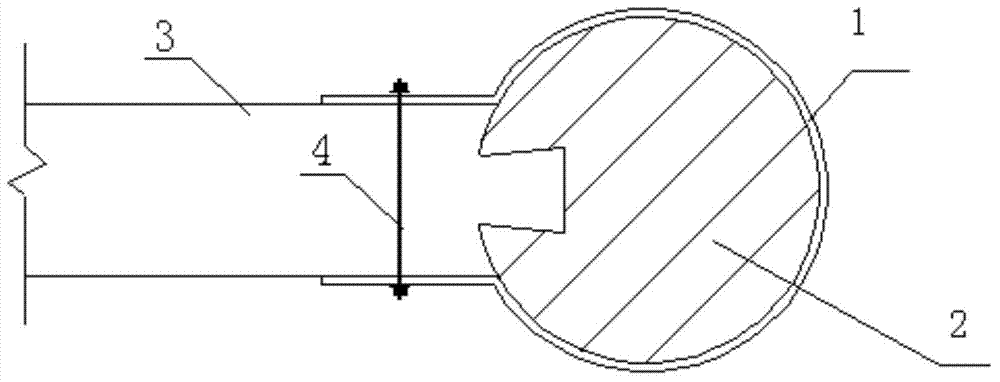

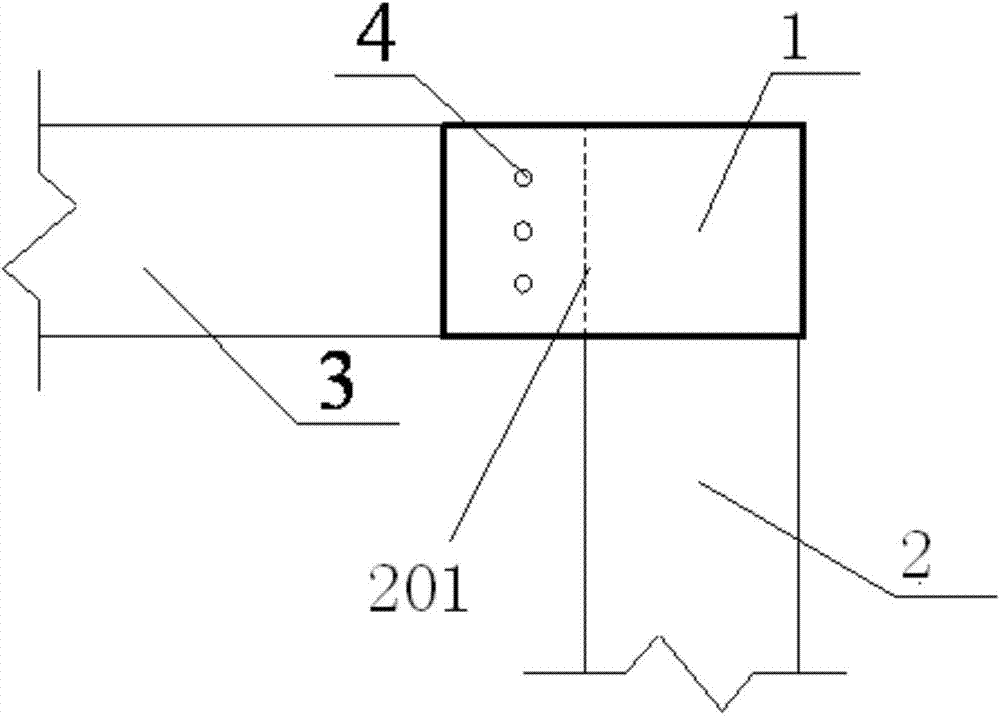

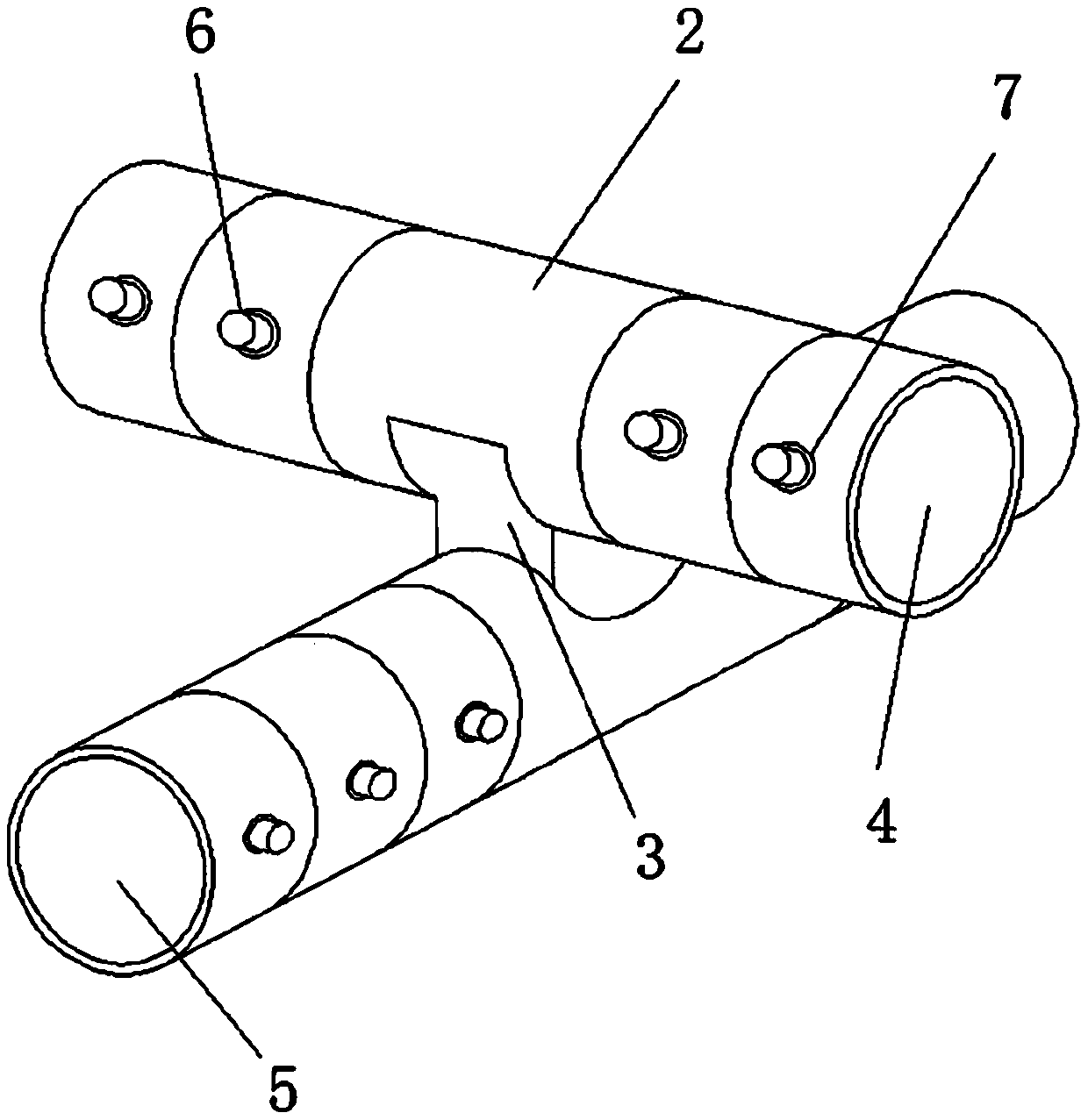

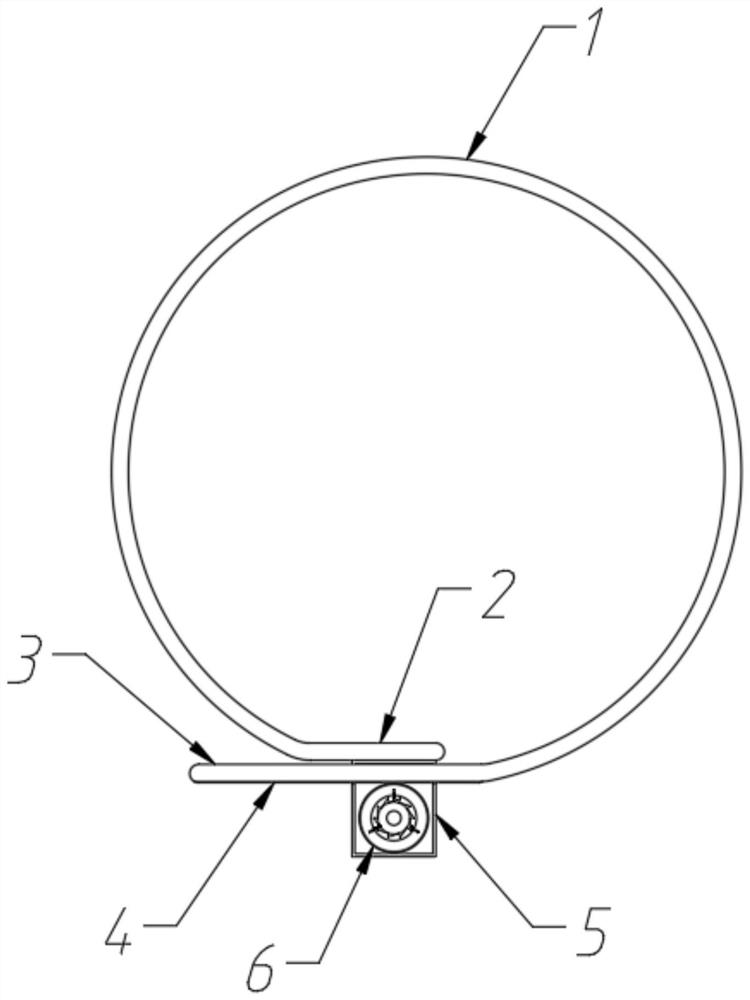

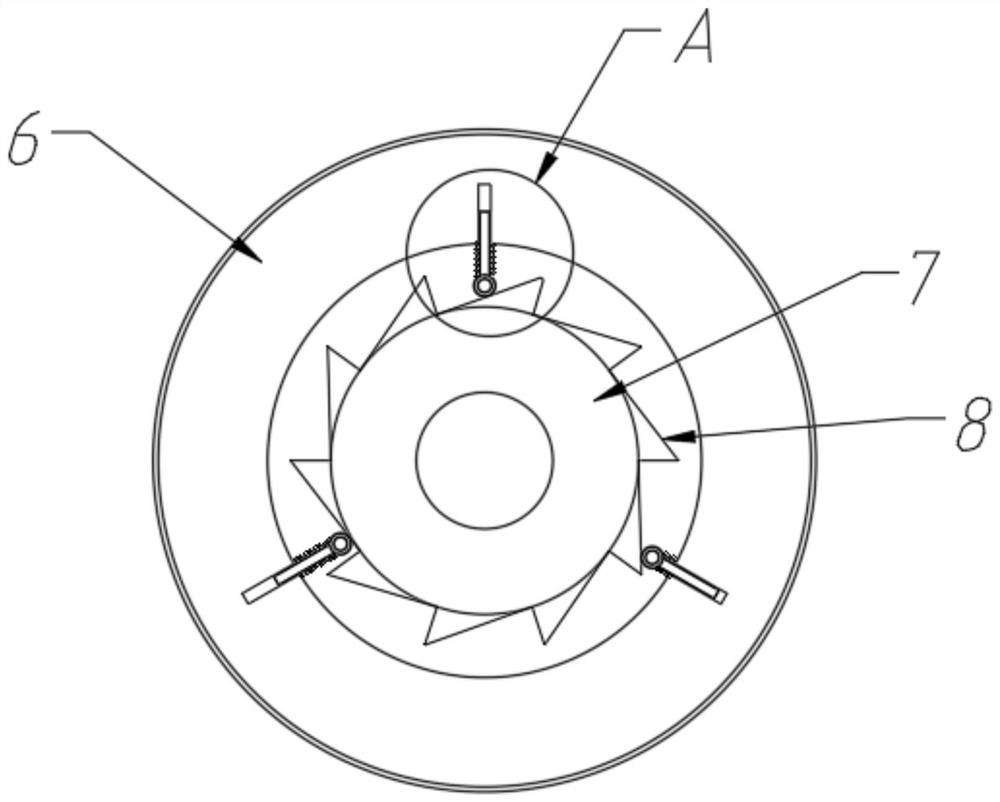

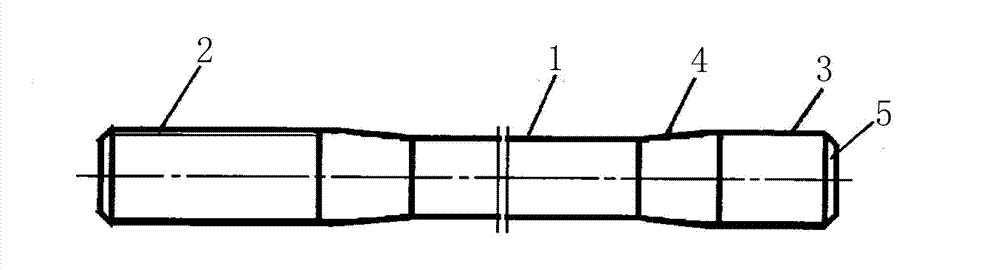

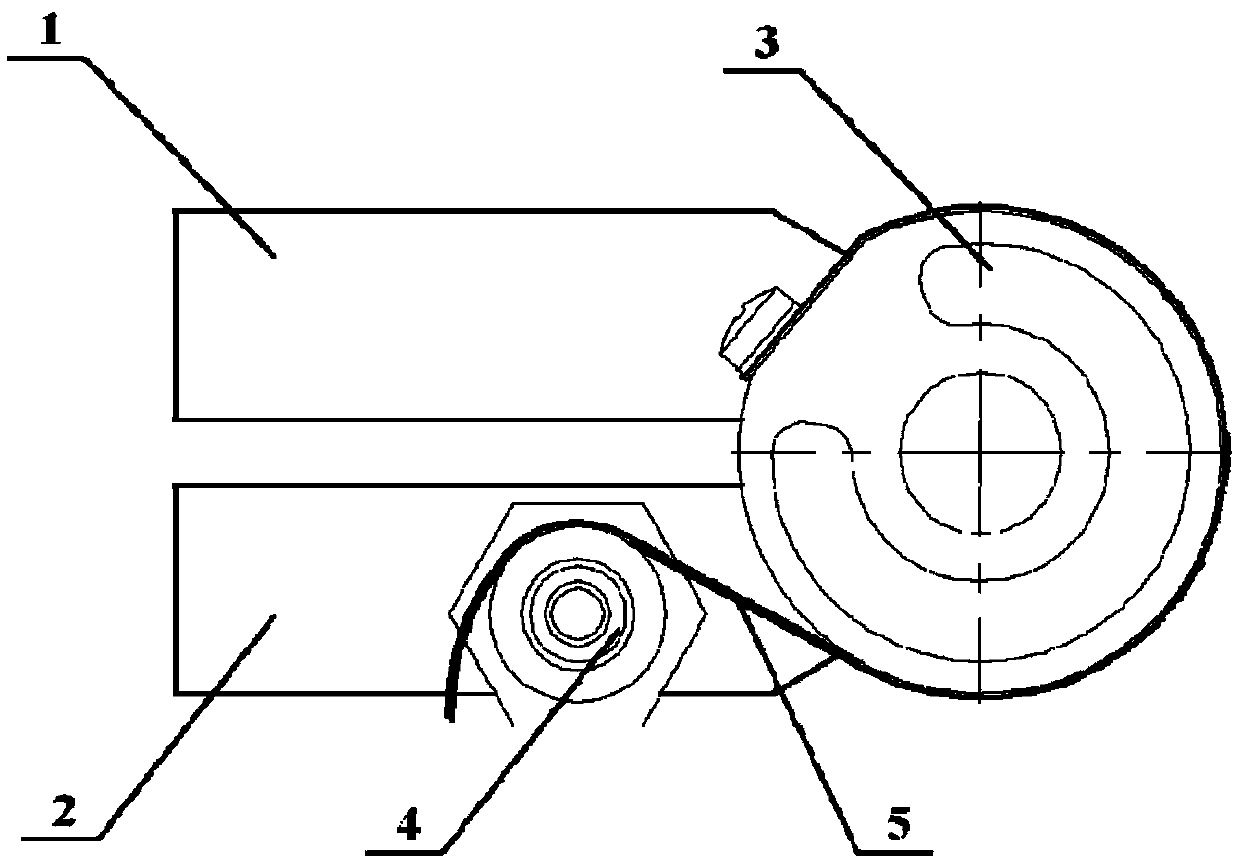

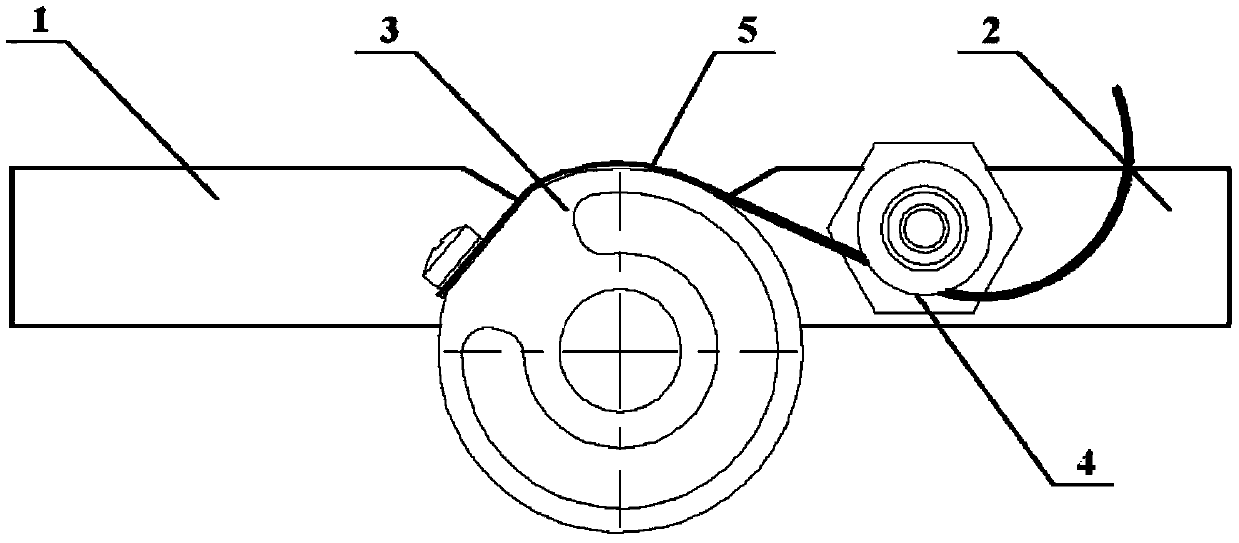

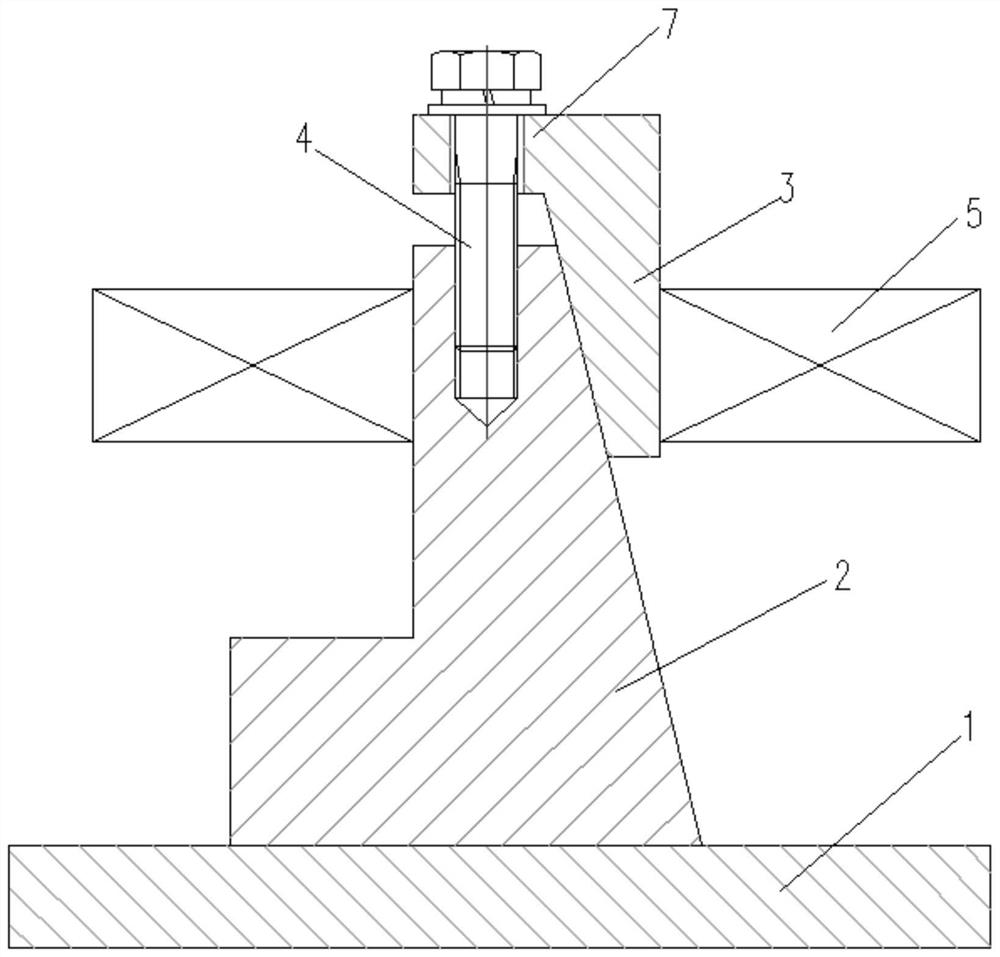

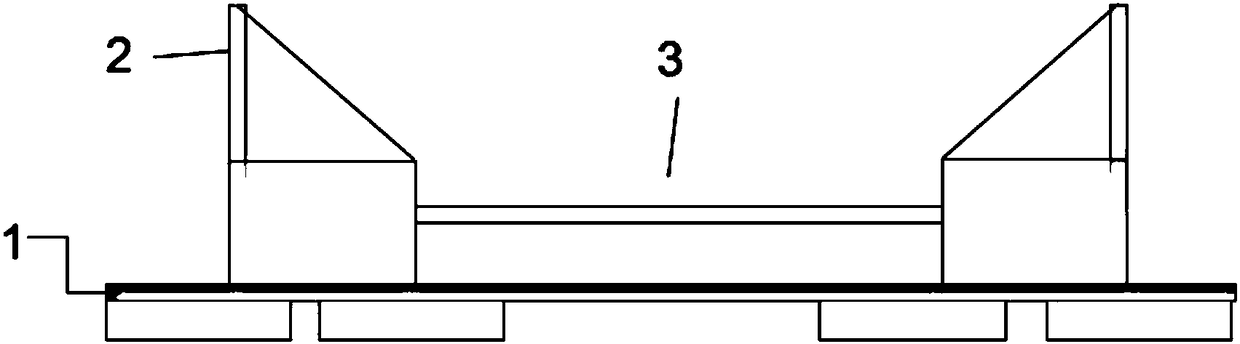

Method for fastening mortise and tenon joint wood frame by using steel hoop

InactiveCN103938884AImproved seismic performance and deformation capacityMeet the requirements for installation and useBuilding repairsMortise and tenonEngineering

A method for fastening a mortise and tenon joint wood frame by using a steel hoop is characterized in that the method includes the following steps of (I) steel hoop (1) processing, wherein the steel hoop (1) is processed according to the size of a wooden column (2) and the size of a wooden beam (3), that is, the height of the steel hoop (1) is the same as the height of the wooden beam (3), the steel hoop (1) is arranged on the wooden column (2) in a sleeved mode, fixing arms extend from the two ends of the opening of the steel hoop (1) and are fixed to the position of the wooden beam (3) at the distance ranging from 100 mm to 150 mm; (II) steel hoop (1) installation, wherein the steel hoop (1) is arranged on a mortise and tenon joint (201) of the wooden column (2) in a sleeved mode, and the steel hoop (1) is fixed to the wooden beam (3) through a bolt (4). According to method for fastening the mortise and tenon joint wood frame by using the steel hoop, the steel hoop is arranged on the mortise and tenon joint position, so that the rigidity and bearing capacity of the joint are improved, the anti-seismic property and deformability of the mortise and tenon joint wood frame are improved significantly, and the requirements of later installation and use are met.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD +1

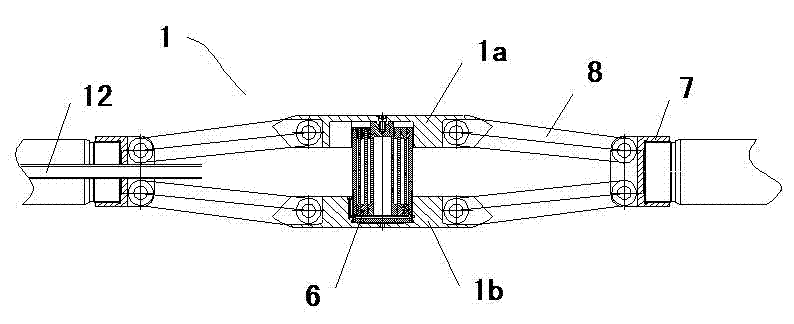

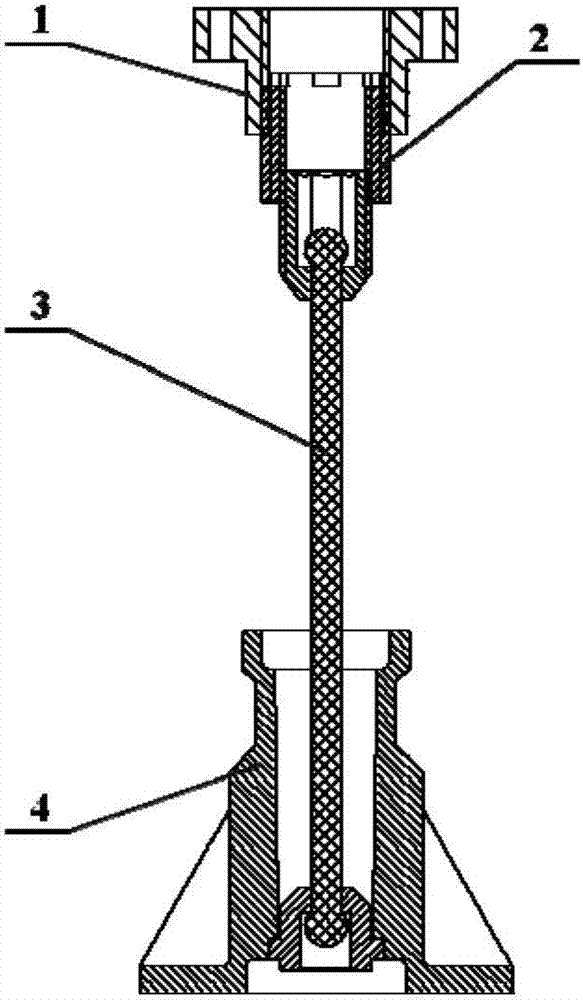

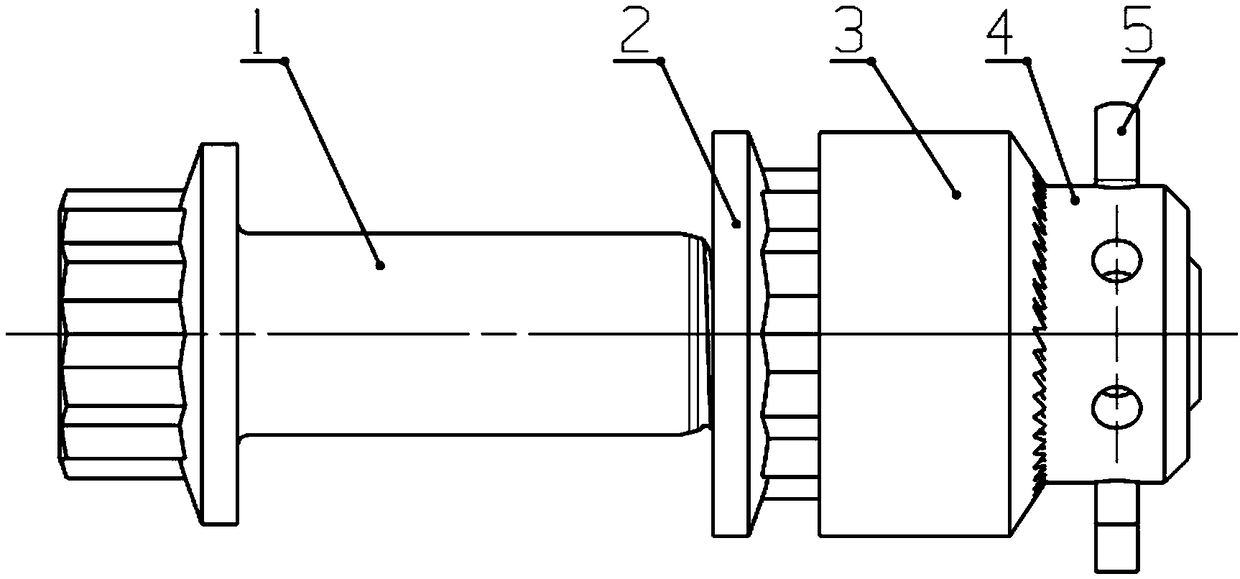

Flexible rope pressing device and using method

ActiveCN103264775BSimple structureIncrease stiffnessCosmonautic vehiclesCosmonautic partsEngineering

The invention discloses a flexible rope pressing device comprising a first assembling component (1), a moving block (2), a rope assembly (3) and a second assembling component (4). The first assembling component (1) and the moving block (2) are connected in a threaded manner through a first threaded direction to realize moving up and down. The upper end of the rope assembly (3) and the moving block (2) are connected in a threaded manner through a second threaded direction to realize moving up and down. The first threaded direction and the second threaded direction is opposite. The lower end of the rope assembly (3) is connected to the second assembling component (4). The invention further discloses a relative using method. The flexible rope pressing device is adaptable to various flexible ropes, a high-rigidity and high-flexibility fixing manner is provided to space unfolding structure pressing, the flexible rope pressing device has the advantages of simple structure, high rigidity, high flexibility, low impact when releasing and high generality.

Owner:SHANGHAI SATELLITE ENG INST

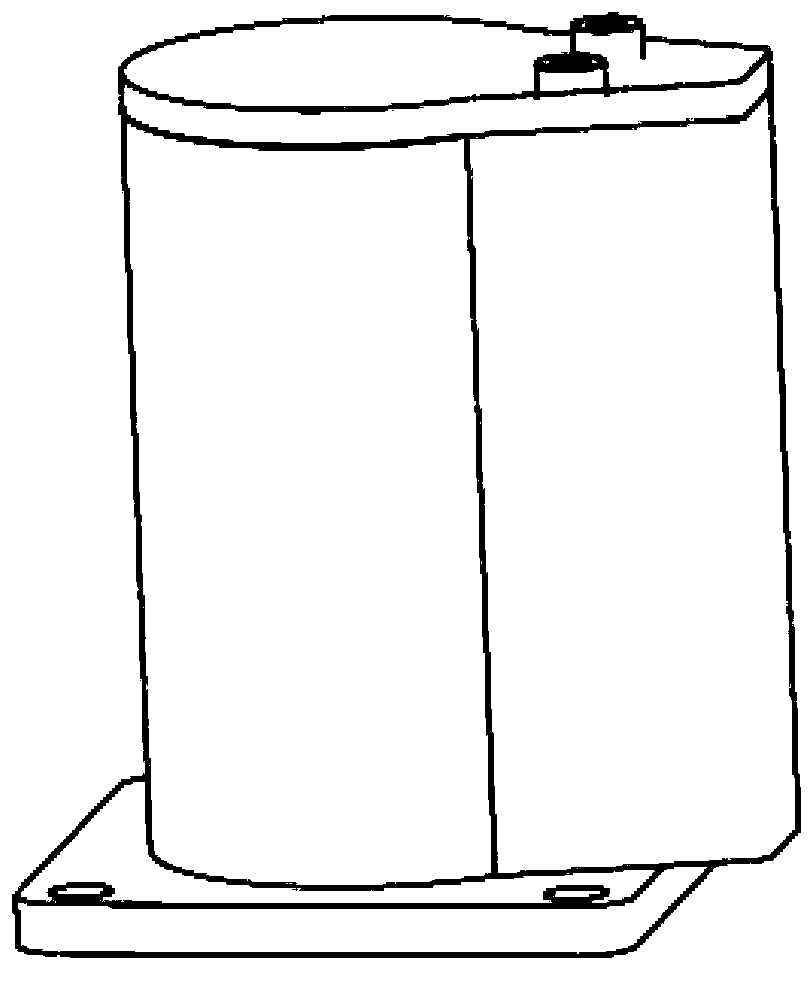

Omnibearing leading-out terminal and leading-out structure of distribution transformer

ActiveCN106373746AReduce exposure to heat effectsEasy to installTransformers/inductances coils/windings/connectionsMulticonductor cable end piecesFuel tankEngineering

The invention discloses an omnibearing leading-out terminal and a leading-out structure of a distribution transformer. The terminal is provided with an insulated mounting seat, a conducting core, a locking nut, a contact terminal, a connecting electrode, a cable connecting mechanism and an insulated external member; the terminal is arranged on an oil tank cover plate of the distribution transformer, when the locking nut is only partially engaged with the cylindrical upper end part of the conducting core, the contact terminal and the connecting electrode positioned on the outside of an oil tank can freely rotate relative to the oil tank cover plate, an installation interface of the connecting electrode can be coincident with the extension direction of an external cable on the site of the distribution transformer, and the external cable does not need to be bent when connected onto the connecting electrode through the cable connecting mechanism, so that the influence of contact heating caused by installation stress is reduced. The direction of connecting the external cable can be adjusted, the terminal has the advantages of convenient mounting, high universality and convenient wiring, the using requirement of product installation can be met to the maximum extent, and the using amount of cables can be saved.

Owner:GUANGDONG BAICHANG ELECTRIC POWER EQUIP CO LTD

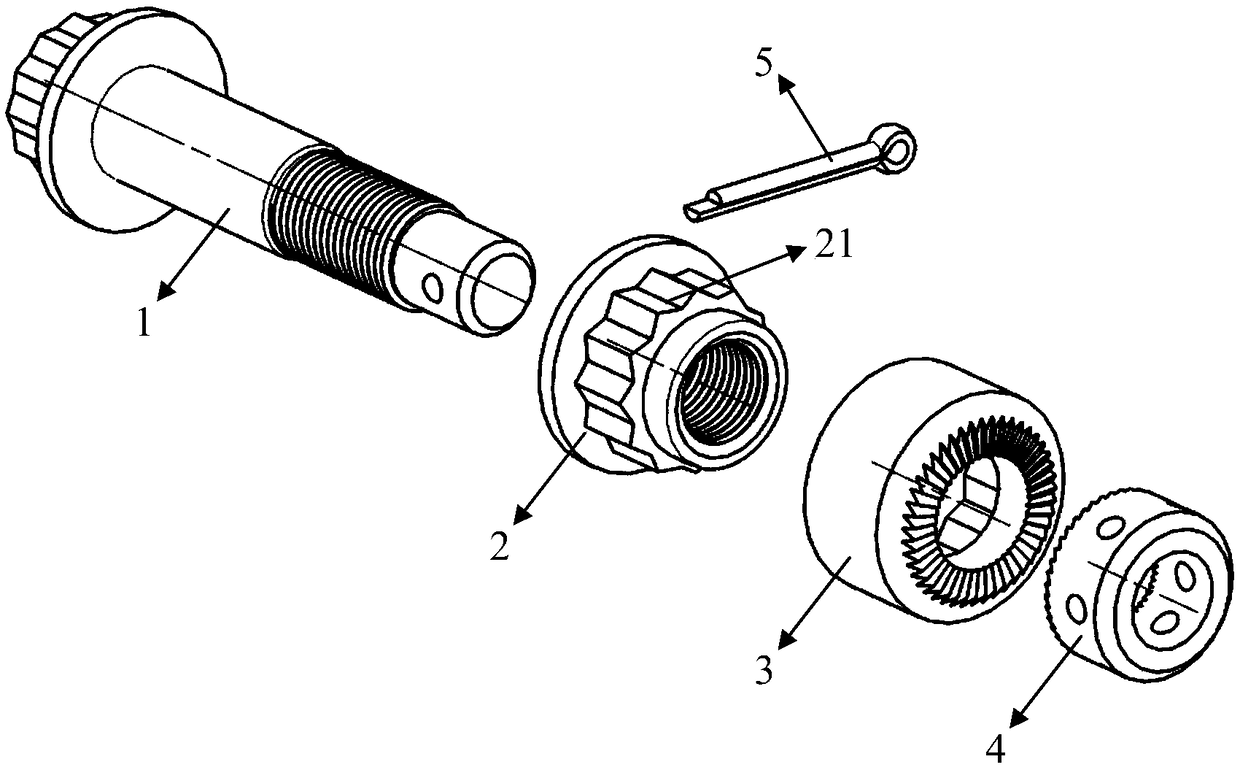

Anti-loose connecting pair

InactiveCN109185315AEasy to disassemble and useStrong anti-loosening abilityNutsBoltsConvex structureEngineering

The invention provides an anti-loose connecting pair. The anti-loose connecting pair comprises a bolt. The bolt can be sequentially sleeved with a nut, a sleeve body and a ring body. A thread part isarranged at the middle portion of a rod body of the bolt. The nut is in threaded fit with the thread part of the bolt. The inner wall, with a concave-convex structure, of the sleeve body is matched and engaged with the peripheral face, similarly with a concave-convex structure, of the nut. A section of smooth wall is further arranged on the inner wall of the sleeve body. A positioning shoulder isarranged between the smooth wall on the inner wall of the sleeve body and the concave-convex structure. The end face of the sleeve body and the end face of the ring body are provided with meshing faces capable of being mutually engaged. The ring body is further provided with a pin body in the radial direction, wherein the pin body can penetrate through the bolt and the ring body. The anti-loose connecting pair can be used in high vibration occasions and achieves heavy load mechanical structure connection, convenient dismounting and mounting can be achieved, the powerful vibration resisting capability is good, the anti-loose connecting pair can bear large axial stretching load and longitudinal shearing load heavy load alternating complex stress fields, the fatigue life is long, and the anti-loose capability is high.

Owner:AEROSPACE PRECISION PROD INC LTD

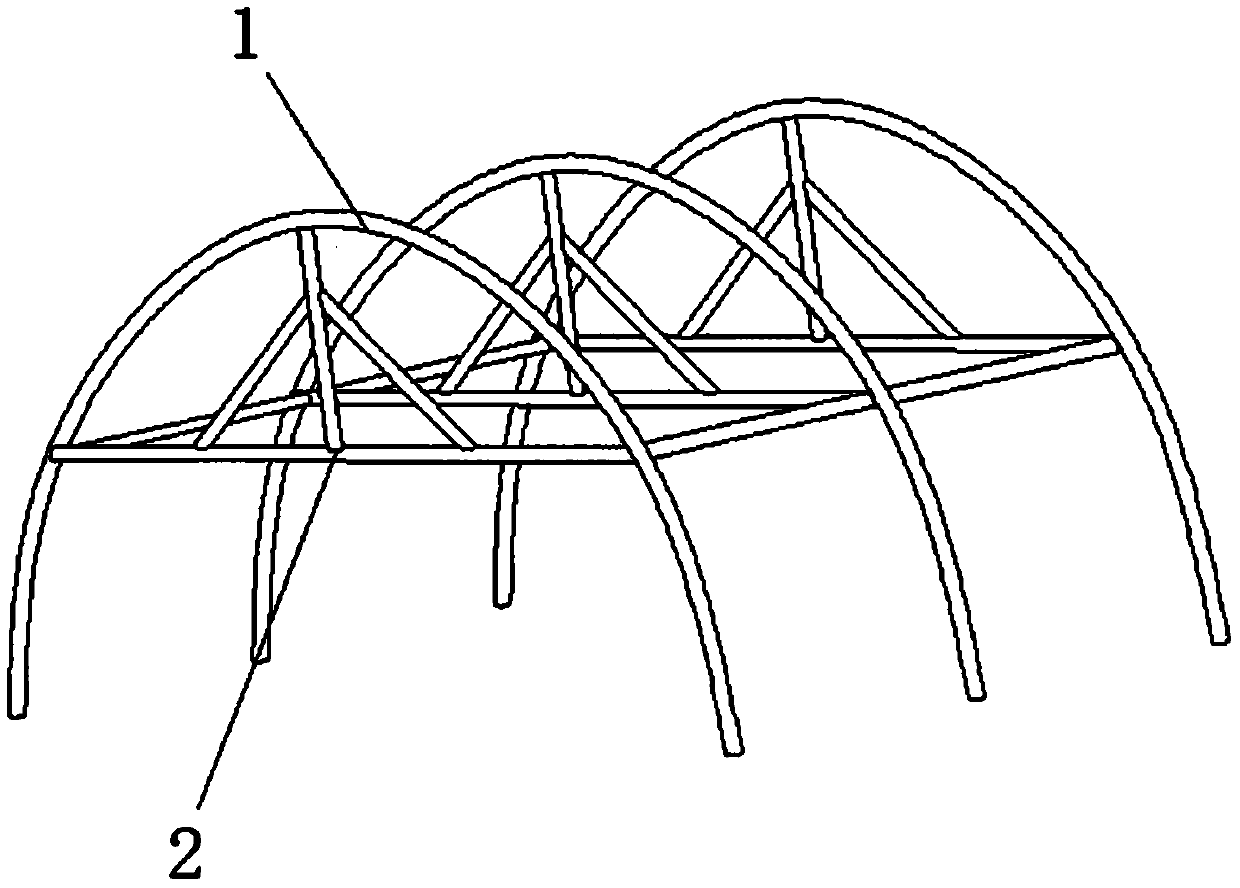

Agricultural greenhouse framework mounting and fixing device having press-type opening and closing structure

InactiveCN111011055AOptimize the installation structureStructure conforms toClimate change adaptationRod connectionsGreenhouseAgricultural engineering

The invention discloses an agricultural greenhouse framework mounting and fixing device having a press-type opening and closing structure. The device comprises greenhouse connecting pipes; each greenhouse connecting pipe is movably provided with a greenhouse connecting piece; each greenhouse connecting piece is fixedly provided with a connecting block; a transverse connecting hole and a longitudinal connecting hole are reserved in each greenhouse connecting piece; each greenhouse connecting piece is fixedly provided with mounting through holes; a loosened clamping block is movably installed ineach mounting through hole; each greenhouse connecting pipe is fixedly provided with a mounting positioning block; and each mounting positioning block is movably provided with a fixing clamping hole.The agricultural greenhouse framework mounting and fixing device having the press-type opening and closing structure is stable in entire structure, can conveniently carry out the operation of fixingand mounting, and reduces the operation difficulty, so that the mounting rate in the whole mounting process is higher, and the operation efficiency is increased; and since a cross-shaped mounting structure is added, the device can better adapt to different mounting positions, better fits to-be-mounted structures, meets the requirements of mounting and using.

Owner:王奕昌

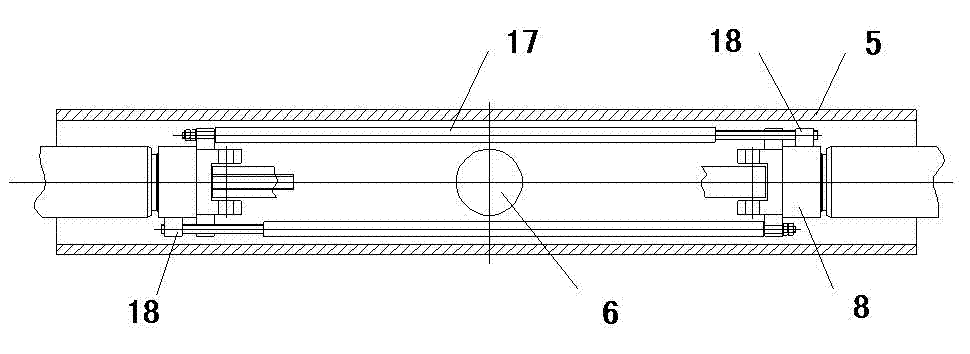

Overall composite inner high-pressure flow type bulging device for car drive axle

InactiveCN102886466AQuality assuranceAccurately control the position of bulging deformationShaping toolsFluid-pressure actuatorsHydraulic cylinderCar driving

The invention relates to an overall composite inner high-pressure flow type bulging device for a car drive axle. The bulging device comprises a bulging inner die, a bulging outer die and two thrust hydraulic cylinders, wherein the bulging inner die comprises an upper die block and a lower die block, and a multi-stage high-pressure flow type hydraulic cylinder is arranged between the upper die block and the lower die block. Two ends of the upper die block and the lower die block are respectively hinged with the piston rods of the two thrust hydraulic cylinders through link mechanisms. The multi-stage high-pressure flow type hydraulic cylinder comprises a high-pressure piston rod and at least two stages of high-pressure hydraulic cylinder bodies which are stacked and sheathed and adopt a telescopic structure, and the high-pressure piston rod is sheathed on the innermost layer of auxiliary hydraulic cylinder body. Oil ports connected with a hydraulic source are arranged in a piston rod chamber and a grading oil chamber of the multi-stage high-pressure flow type hydraulic cylinder, and two circulating oil ports are arranged in a rodless chamber. The bulging outer die comprises a support mechanism positioned on the transitional surface of an axle shell pipa bag. The piston rods of the two thrust hydraulic cylinders are oppositely arranged, and the axes of the two piston rods are positioned on the same one straight line. Moreover, a quick-detached connecting structure is arranged on the piston rod of one thrust hydraulic cylinder.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

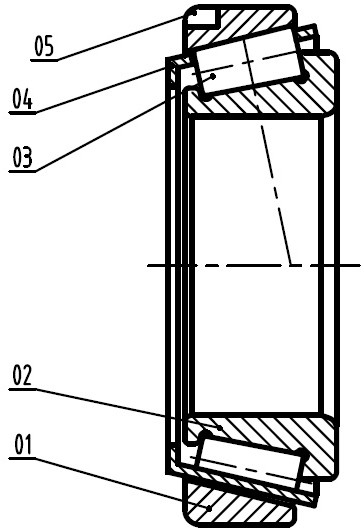

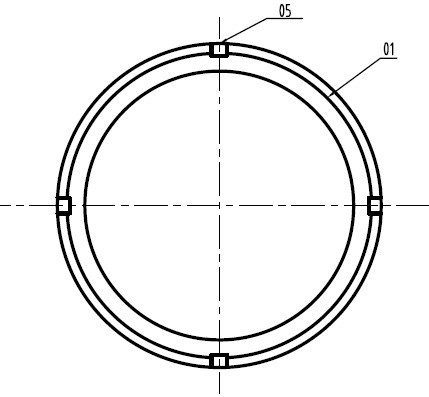

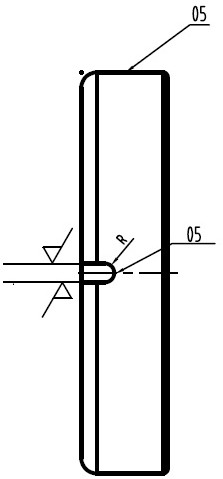

Tapered roller bearing with positioning groove in outer ring end face

PendingCN112576616AAccurate installation and positioningEasy to useRoller bearingsBearing componentsInterference fitEngineering

The invention discloses a tapered roller bearing with a positioning groove in an outer ring end face, and belongs to the technical field of automobile parts. The tapered roller bearing mainly solves the problems of interference fit requirements of manufacturers under special mounting conditions and difficulty in mounting and dismounting large bearings and bearings which are frequently dismounted.The tapered roller bearing is mainly characterized by comprising an inner ring, an outer ring, a retainer and rolling bodies, a key groove is formed in the position where the end surface of the outerring is connected with and corresponds to the outer diameter; after the bearing and the shell are assembled, a bearing ring and a matching surface are matched through the flat key groove to perform circumferential positioning, so that the aims of accurately mounting, positioning and using the bearing and conveniently mounting and dismounting the bearing are fulfilled, and the mounting and using requirements of the manufacturers are met. The tapered roller bearing has the characteristics of simple structure, accurate positioning and convenience and quickness in mounting and dismounting, and ismainly used for front and rear axles of bridge factories and engineering trucks.

Owner:XIANGYANG AUTOMOBILE BEARING CO LTD

New Vibration Isolator for Satellite Sensitive Payloads

The invention discloses a novel vibration isolator used for a satellite sensitive load. The novel vibration isolator used for the satellite sensitive load comprises an upper installation unit, a lower installation unit and a main vibration isolation unit, wherein the upper installation unit, the lower installation unit and the main vibration isolation unit are of an integral structure. The novel vibration isolator used for the satellite sensitive load provided by the invention has the following technical characteristics: I, the installation of satellite sensitive load equipment is ensured; II, vibration transferred to the effective load by a satellite platform is isolated to ensure the normal operation of the effective load; III, the vibration disturbance of the effective load is isolated. While the sensitive load is supported, the goal that the sensitive load can normally work in orbit reliably, safely and effectively is achieved.

Owner:SHANGHAI SATELLITE ENG INST

Suspension Mechanism for Additional Conductors of Catenary in Electrification of High Speed Railway

ActiveCN103434418BEliminate gap dischargeMeet the requirements for installation and useTrolley linesEngineeringWear resistance

Owner:陕西万里达铁路电气化器材有限公司

Vertical semi-direct-drive permanent magnet synchronous motor

PendingCN114552930AAchieve high integrationImprove reliabilityMagnetic circuit rotating partsElectric machinesPermanent magnet synchronous motorContact position

The invention discloses a vertical semi-direct-drive permanent magnet synchronous motor which comprises an integral base, a transmission output mechanism and a vertical permanent magnet synchronous motor assembly are mounted in the integral base, the integral base comprises an outer shell, a mounting seat is integrally formed in the outer shell, and the integral base is divided into a first area and a second area by the mounting seat. The vertical permanent magnet synchronous motor assembly is connected with the transmission output assembly, an output end cover for sealing the first area is arranged on the integral base, a first sealing assembly is arranged at the contact position of the output end cover and the transmission output mechanism, and a second sealing assembly is arranged at the contact position of the installation base and the permanent magnet synchronous motor assembly. A vertical permanent magnet synchronous motor assembly and transmission output mechanism integrated scheme is adopted, high integration of a power device and a transmission device is achieved, the advantages of high efficiency, energy conservation, compact structure, low manufacturing and operation and maintenance cost, high reliability and the like are achieved, the sealing reliability of equipment can be remarkably improved by adopting a combined sealing assembly, and the manufacturing and operation and maintenance cost of the equipment is improved.

Owner:江苏中工高端装备研究院有限公司

Self-adaptive garden tree cold-proof belt

InactiveCN111837774AGrowth does not affectMeet the requirements for installation and useHorticulture methodsPlant protective coveringsStructural engineeringMechanical engineering

The invention discloses a self-adaptive garden tree cold-proof belt. The cold-proof belt comprises a belt body and a connecting mechanism used for connecting a fixed end with a free end, wherein the inner layer of the belt body is a heat insulating layer, the outer layer is a wrapping layer, one end of the belt body is the fixed end, and the other end is the free end; the belt body makes a circlethrough the connecting mechanism; and the connecting mechanism comprises a mounting block, a rack and a rotating ring, the mounting block is fixedly connected with the wrapping layer at the fixed end,a mounting through groove is formed in the mounting block, the free end penetrates through the mounting through groove, and a rotating groove communicating with the mounting through groove is formedin the mounting block, the rack is fixedly connected with the wrapping layer at the free end; and the rotating ring is rotationally arranged in the rotating groove. The shrinking movement tend of thecircle surrounded by the belt body has fluctuating change in a certain range, the overall cold-proof belt is in a relatively stable state and cannot become large all the time with growth of trees, andthe growth of the trees cannot be affected.

Owner:余高强

Bolt for blade

InactiveCN103244537AMeet the requirements for installation and useMeet the use requirementsScrewsPerformance indexEngineering

The invention discloses a bolt for a blade. The bolt is characterized in that long threads and short threads are respectively arranged at two ends of a threaded rod, the outer diameter of each of the long threads and the short threads is slightly larger than that of the threaded rod, conical oblique planes are respectively arranged on the inner side of the long threads and the inner side of the short threads, and chamfers are respectively arranged at the outer end of the long threads and the outer end of the short threads. The bolt for the blade has the advantages that service requirements on the external shape and various performance indexes under the condition that the temperature is minus 40 DEG C are met, installation and service requirements of various generating sets with fans are met, and land and marine service requirements under severe conditions across the world are met.

Owner:SHANDONG GAOQIANG FASTENER

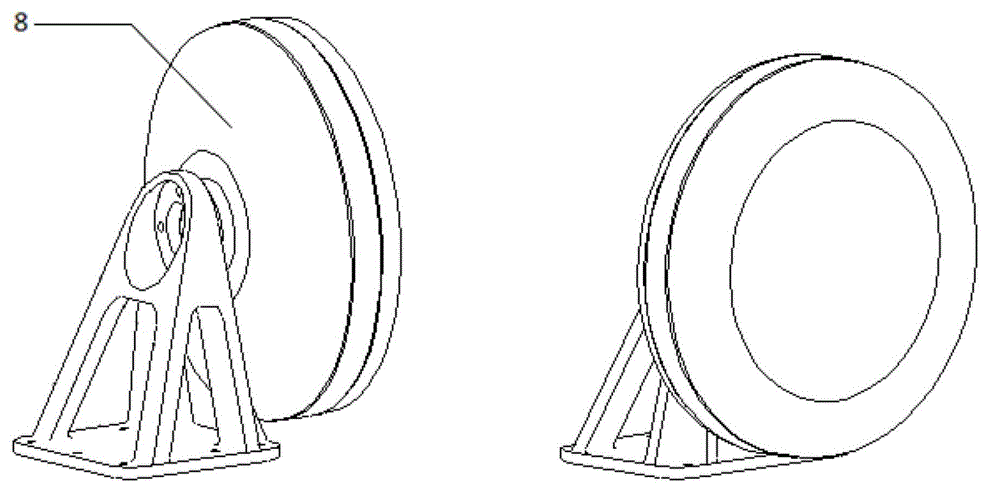

Spatial Constant Moment Passive Drive Device

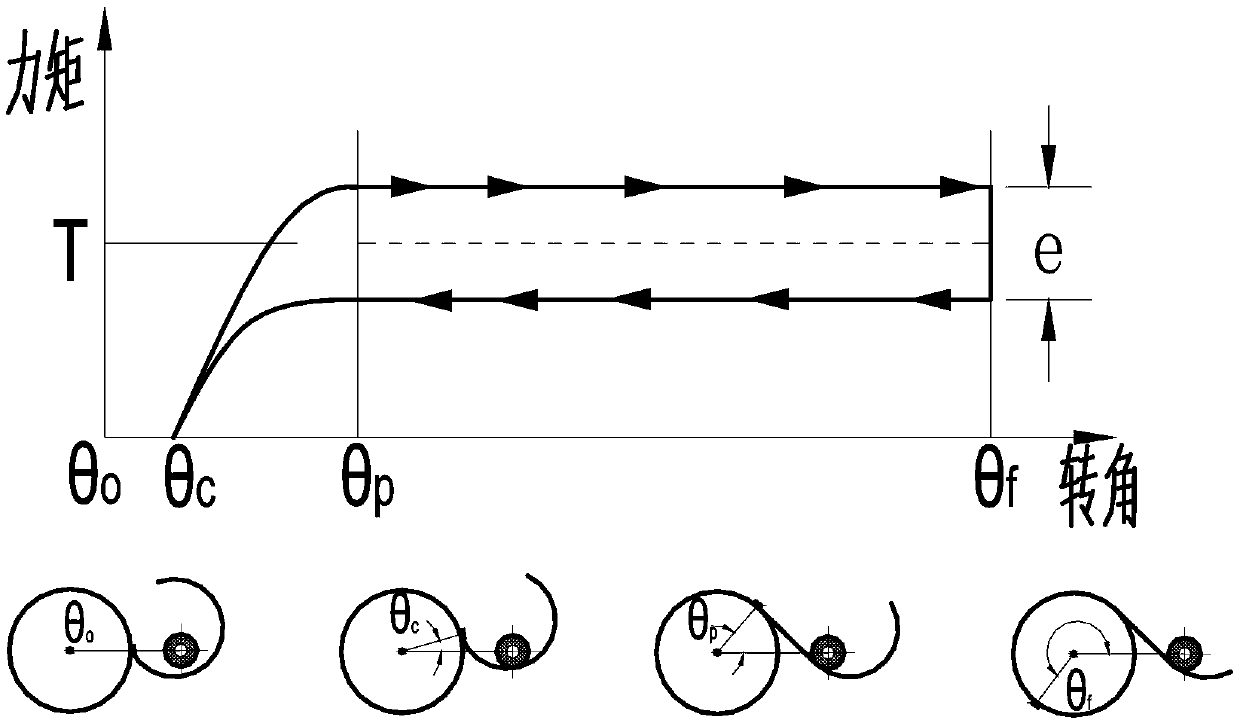

ActiveCN103241388BConstant torqueReduce shockCosmonautic vehiclesCosmonautic partsSpace constantMechanical engineering

The invention provides a space constant torque passive driving device comprising a first mounting portion, a second mounting portion, a spring fixing disc, a spring guiding disc and an energy storage spring. The first mounting portion is connected with the second mounting portion through a shaft. The spring fixing disc is connected with the first mounting portion. The spring guiding disc is connected with the second mounting portion. The energy storage spring is connected with the spring fixing disc and the spring guiding disc respectively. The pace constant torque passive driving device has the advantages of constant torque, small impact, wide torque outputting range and high generality.

Owner:SHANGHAI SATELLITE ENG INST

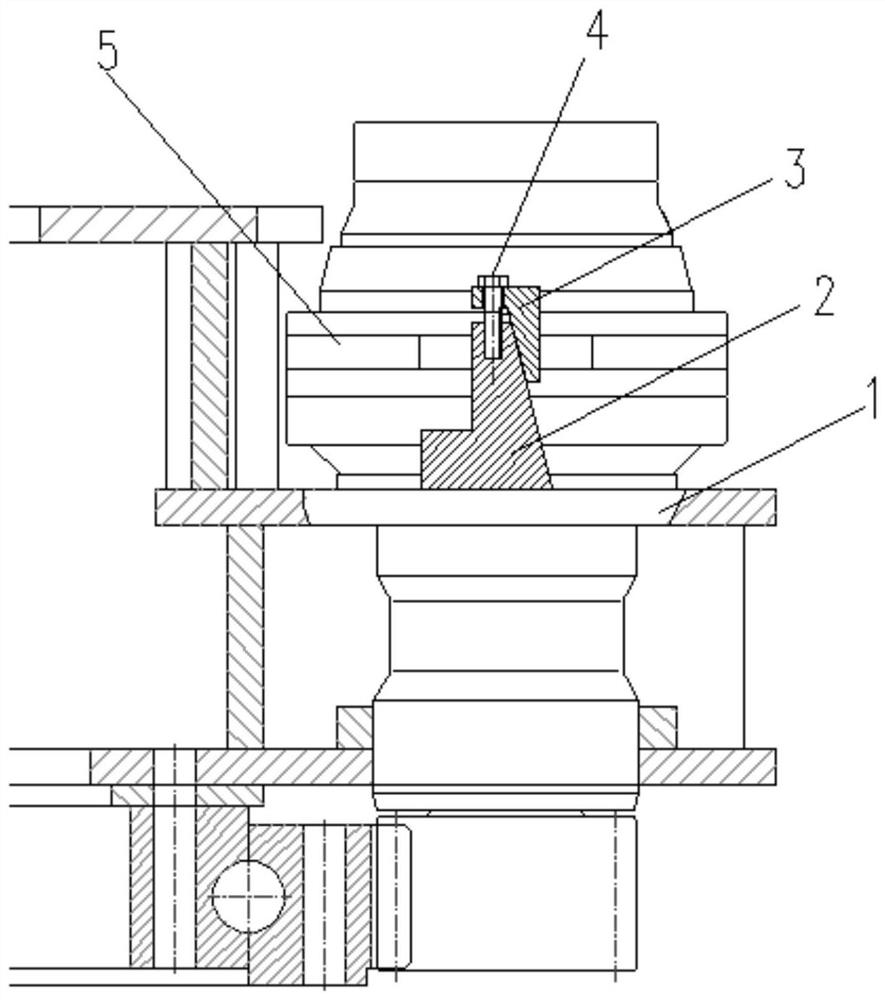

Tower crane slewing mechanism mounting method

The invention discloses a tower crane slewing mechanism mounting method. A mounting device comprises a fixed support mounted on a slewing bearing frame, a wedge block matched with the fixed support and a connecting piece, the fixed support is in a wedge shape with the wide lower portion and the narrow upper portion, the inclined face of the wedge block is matched with the upper portion wedge-shaped inclined face of the fixed support, the upper portion of the wedge block horizontally extends to form a top cover, the connecting piece penetrates through the top cover to fix the wedge block on the fixed support, the slewing bearing frame is fixed on the side edge of the slewing mechanism, a bayonet is formed in a rotating arm of the slewing mechanism, and the bayonet is aligned with the fixed support for installation. According to the tower crane slewing mechanism mounting method, and efficient machining of the slewing bearing frame, stable installation of the slewing mechanism and rapid installation of the slewing mechanism are achieved.

Owner:GUANGXI CONSTR ENG GROUP CONSTR MACHINERY MFG

A kind of marine heavy crane and underwater installation process

ActiveCN106564819BMeet the requirements for installation and useImprove installation accuracyCranesMarine engineeringTower

The invention discloses a heavy crane for ships and an underwater installation technology, the heavy crane for the ships comprises a support base, a tower body, a lifting arm, a steel wire rope and a hook, the lower end of the tower body is connected with the support base, the lifting arm is connected with the flange face of the tower body, one end of the steel wire rope is connected with the lifting arm, the other end of the steel wire rope is connected with the hook, and the support seat comprises a center seat, a plurality of adjustable auxiliary seat sets and an electric device. The underwater installation technology for the heavy crane for the ships is as follows: pre order preparation work, a tower body installation process, a lifting arm installation process and finishing work, the main installation steps are as follows: using a 200t engineering floating crane to lift the tower body about 110t for alignment connection with the support seat, using two quay cranes for combined lifting to lift the lifting arm about 65t, and aligning the flange face of the lifting arm for connection with the tower body. The heavy crane for the ships can shorten the shipbuilding cycle, and has the advantages of ingenious design, convenient installation and the like.

Owner:TAIZHOU SANFU SHIP ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com