Loop gravity-assisted heat pipe heat transfer device

A gravity heat pipe and loop technology, which is applied to the heat transfer principle and device field of a new loop gravity heat pipe, can solve the problems of high engineering cost, high construction difficulty, inconvenience, etc., so as to increase the heat transfer area of the cold end and improve the heat transfer. Efficiency, the effect of reducing heat transfer thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

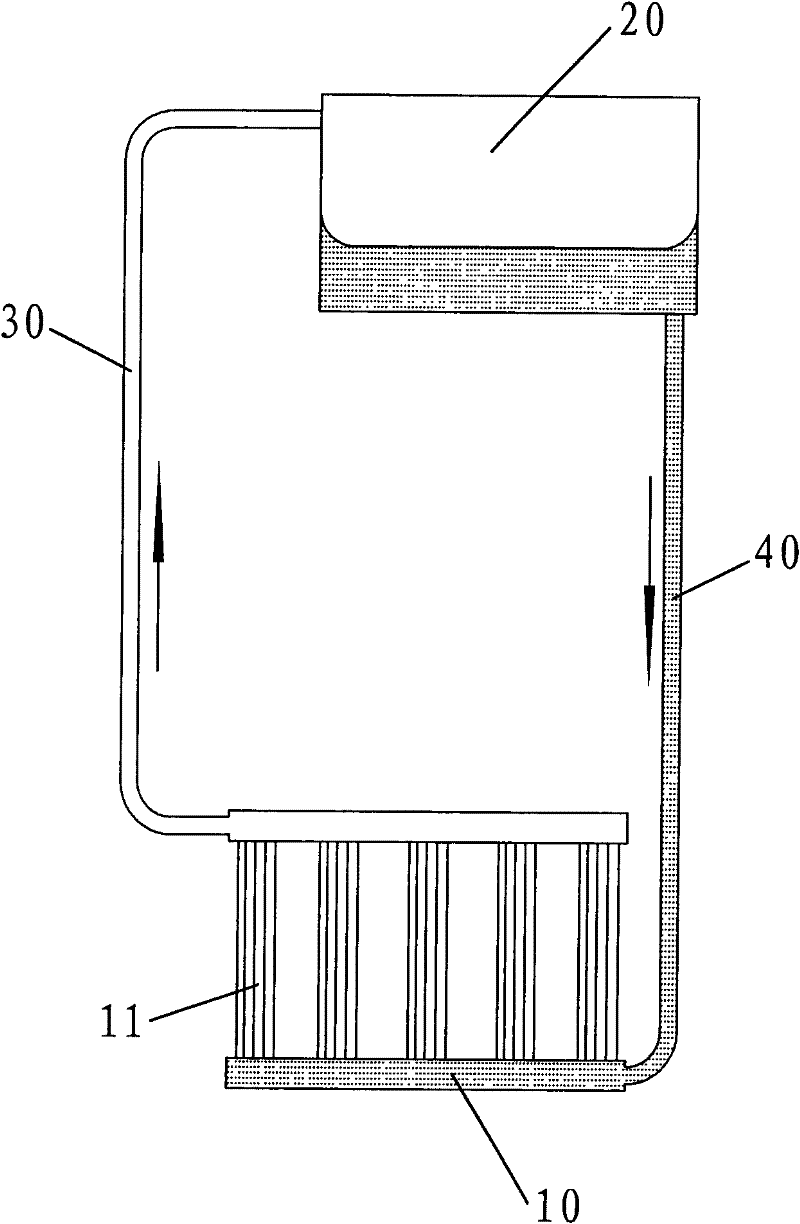

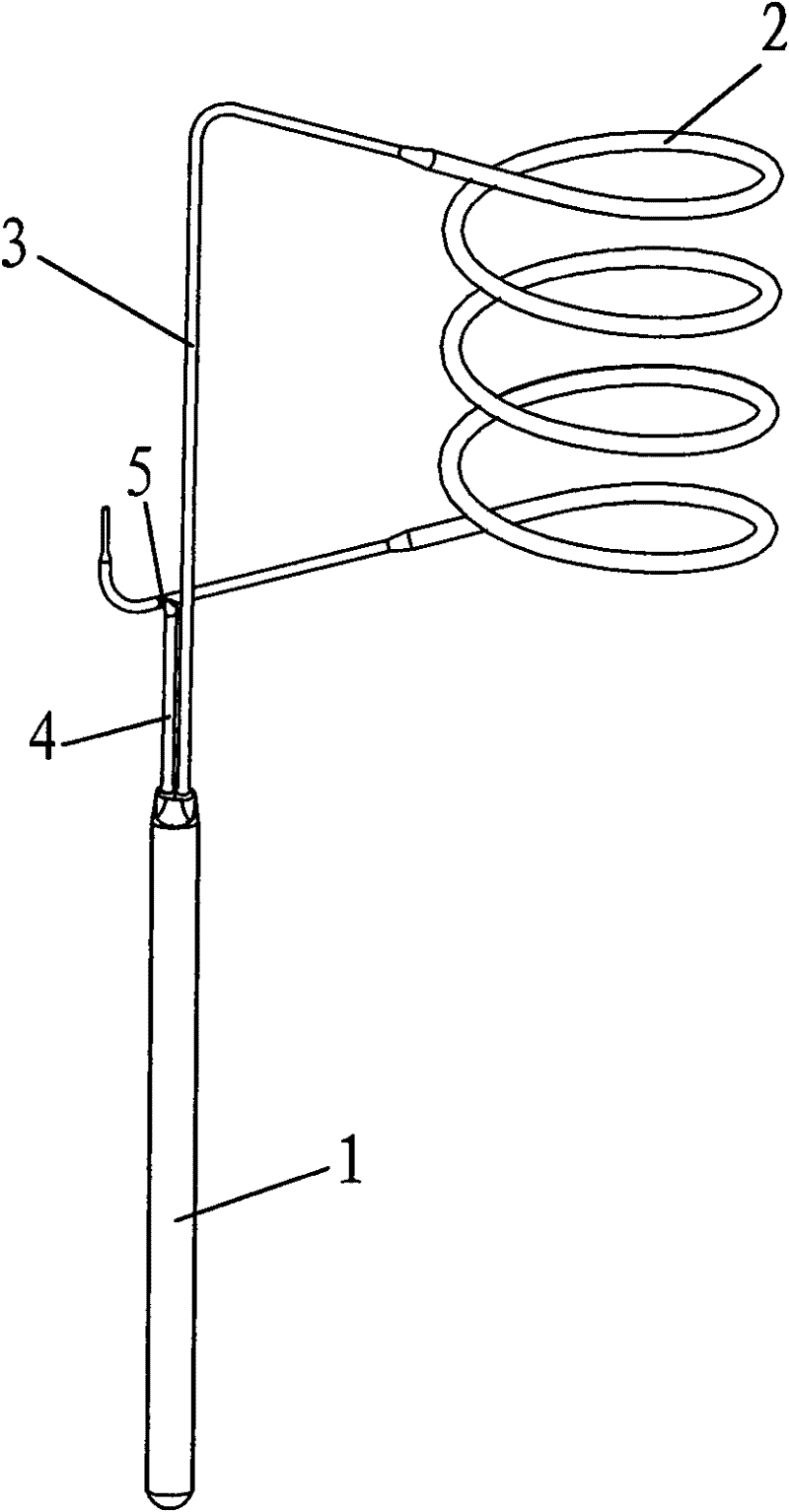

[0044] see image 3 As shown, a loop gravity heat pipe heat transfer device of the present invention mainly includes an evaporator 1 , a condenser 2 , a steam pipeline 3 and a liquid pipeline 4 .

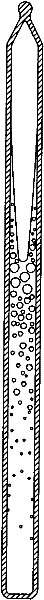

[0045] Among them, please refer to Figure 4 As shown, the evaporator 1 is a tubular evaporator, which is sealed inside and equipped with a working medium 7. The inlet of the steam pipeline 3 is slightly protruded into the top of the evaporator 1, and the outlet of the liquid pipeline 4 passes through the top of the evaporator 1 and is inserted into the Bottom of evaporator 1. The inner surface of the shell of the evaporator 1 can be Figure 5 The smooth surface shown in (a) can also be other structured surfaces to enhance boiling heat transfer and liquid reflux capabilities, such as Figure 5 The straight grooved surface shown in (b), Figure 5 The surface of the spiral groove shown in (c), the spiral groove structure can be continuous or discontinuous, and can also be as Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com