Tower crane slewing mechanism mounting method

A technology of slewing mechanism and tower crane, which is applied in the direction of cranes, etc. It can solve the problems of installation failure of slewing mechanism, increase bearing torque, time-consuming and labor-intensive problems, so as to solve the problem of easy loosening of bolt groups, improve processing efficiency and solve assembly difficulties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

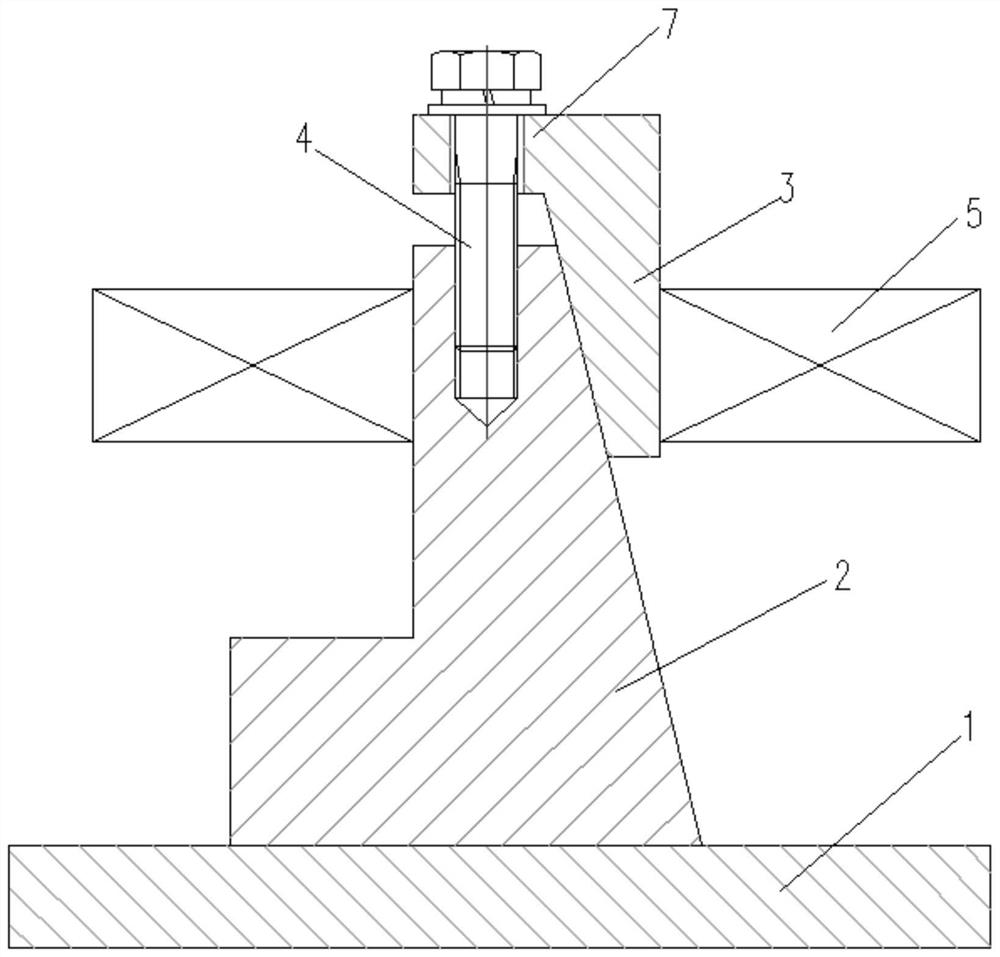

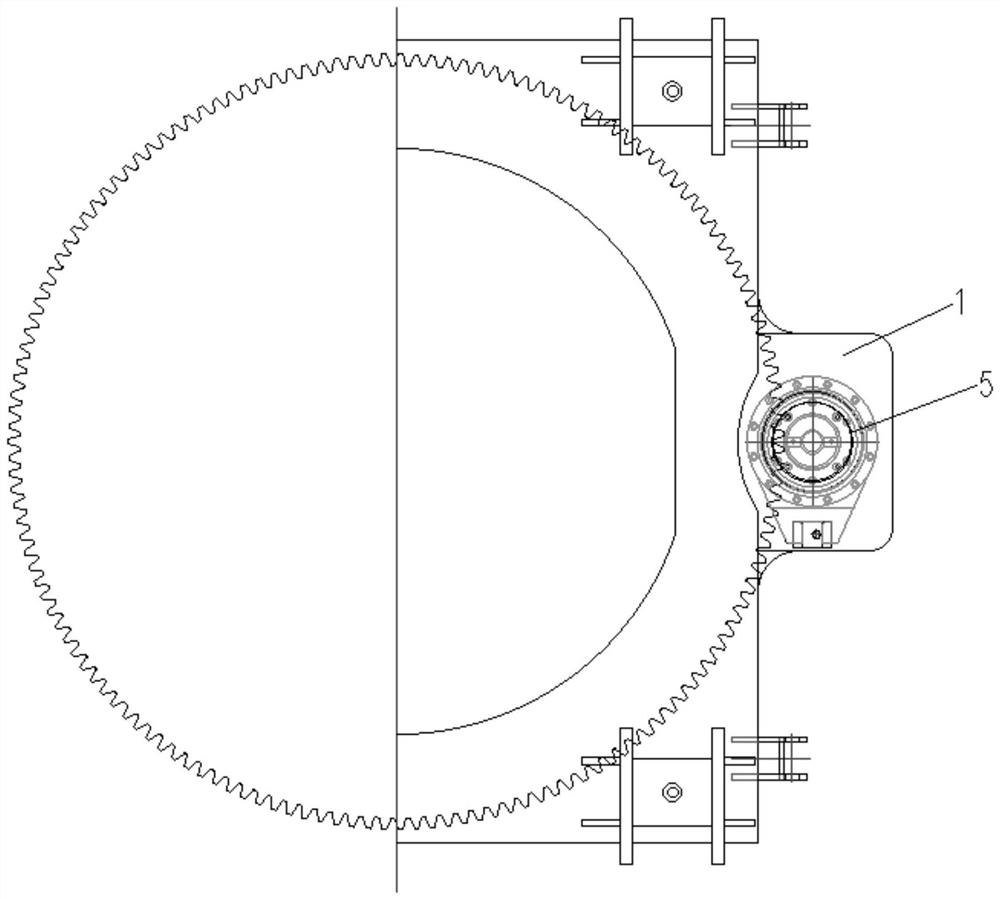

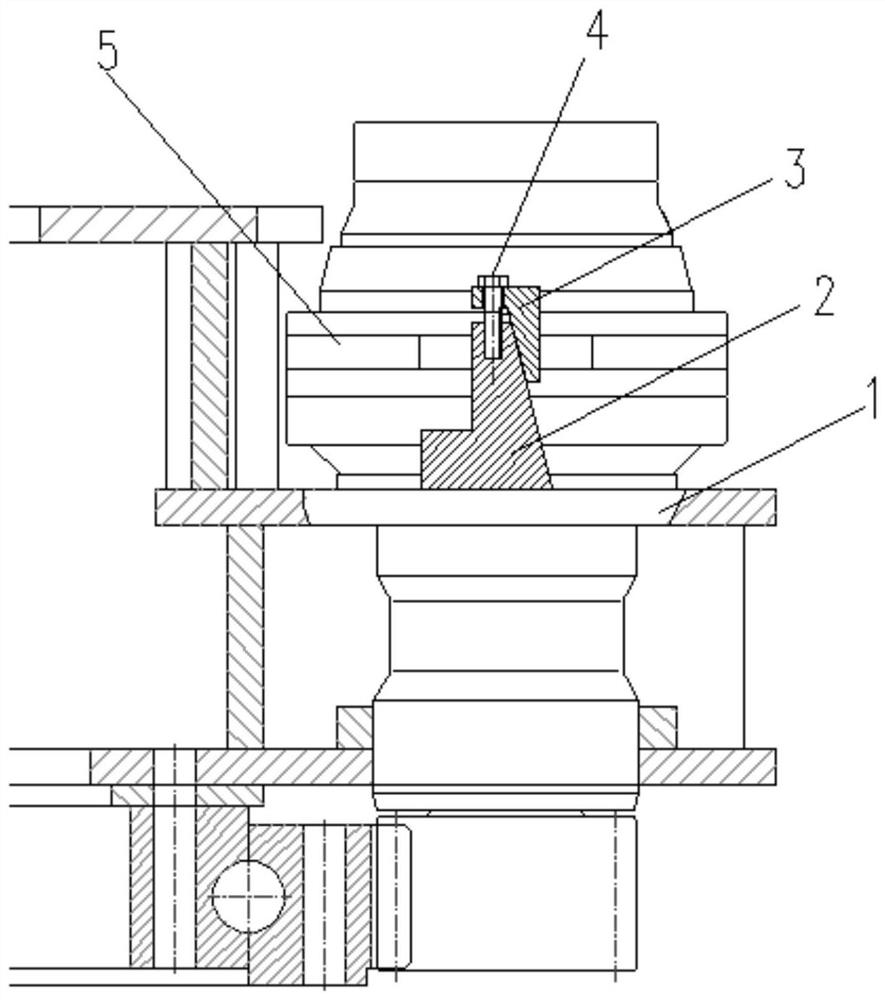

[0026] Such as figure 1 As shown, a tower crane slewing mechanism installation device includes a fixed support 2 installed on the slewing support frame 1, a wedge 3 and a connecting piece 4 adapted to the fixed support 2, and the fixed support 2 is the bottom Wide and narrow wedge-shaped, the slope of the wedge 3 is adapted to the upper wedge-shaped slope of the fixed support 2, the upper part of the wedge 3 extends horizontally to form a top cover, and the connecting piece 4 penetrates the top cover to connect the wedge 3 Fixed on the fixed support 2, the slewing support frame 1 is fixed on the side of the slewing mechanism 5, and a bayonet is provided on the rotating arm 6 of the slewing mechanism, and the bayonet is aligned with the fixed support 2 for installation. According to the assembly and force characteristics of the slewing mechanism 5, a fast, simple and stable installation method is developed, and at the same time, the slewing mechanism can be assembled quickly, e...

Embodiment 2

[0034] A method for installing a slewing mechanism of a tower crane. A slewing mechanism arm 6 is provided on the slewing mechanism, a bayonet opening is provided on the slewing mechanism arm, and a mounting assembly detachably engaged by a wedge is provided at the bayonet. The installation device The bottom of the slewing support frame is fixed on the slewing support frame, and the entire installation device is clamped in the bayonet. The key problems to be solved are: 1. The fixed support of the slewing mechanism is directly welded on the slewing support frame, which solves the problem of the installation bolt group of the slewing support frame slewing mechanism. The machining of the mounting holes is cumbersome, and it is difficult to require high precision. 2. Improve the stability of the installation of the slewing mechanism and the efficiency and simplicity of the processing of the slewing support frame and the installation of the slewing mechanism.

[0035] The installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com