On-track monitoring device for tension of spacecraft rope

A rope tension and monitoring device technology, applied in the direction of tension measurement, etc., can solve the problems of complex conditioning circuits, large weight and resources, large weight and volume, etc., and achieve the effect of broad application prospects, simple interface and correct principle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention are described in detail below: this embodiment is implemented under the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided. It should be noted that those skilled in the art can make some modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

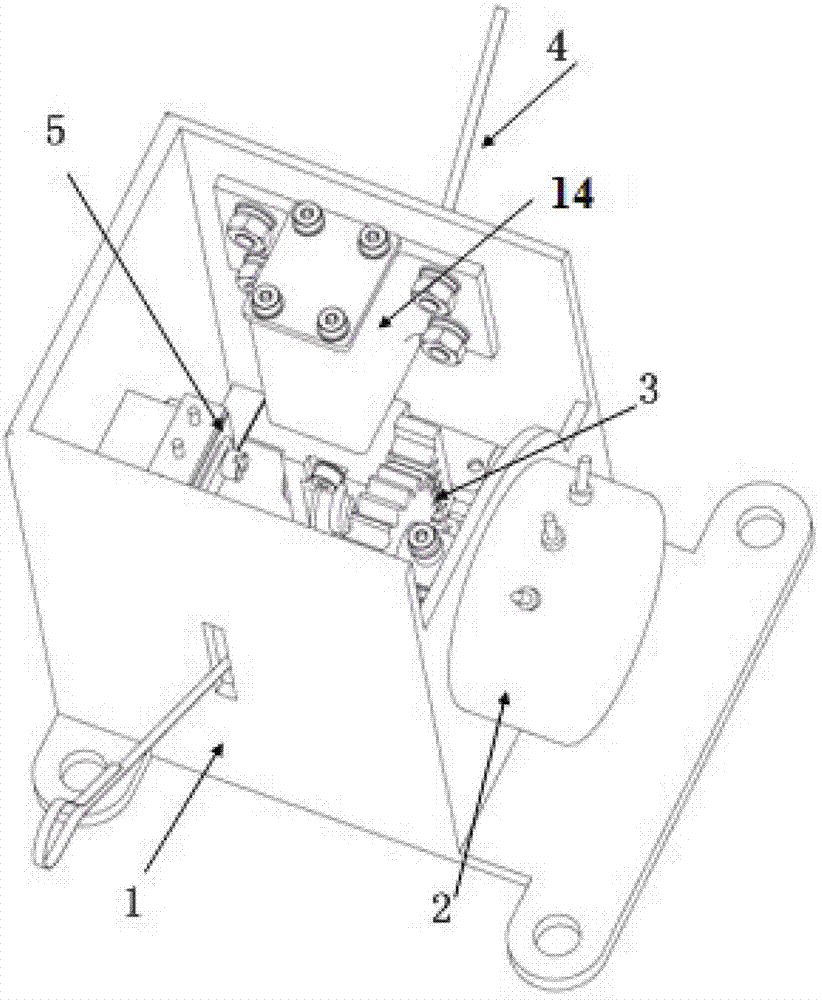

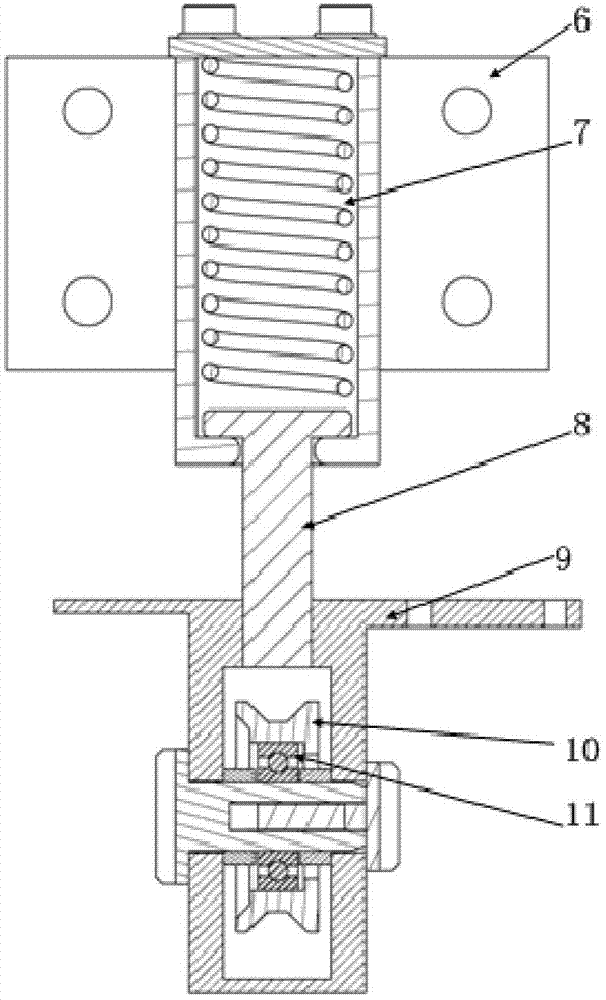

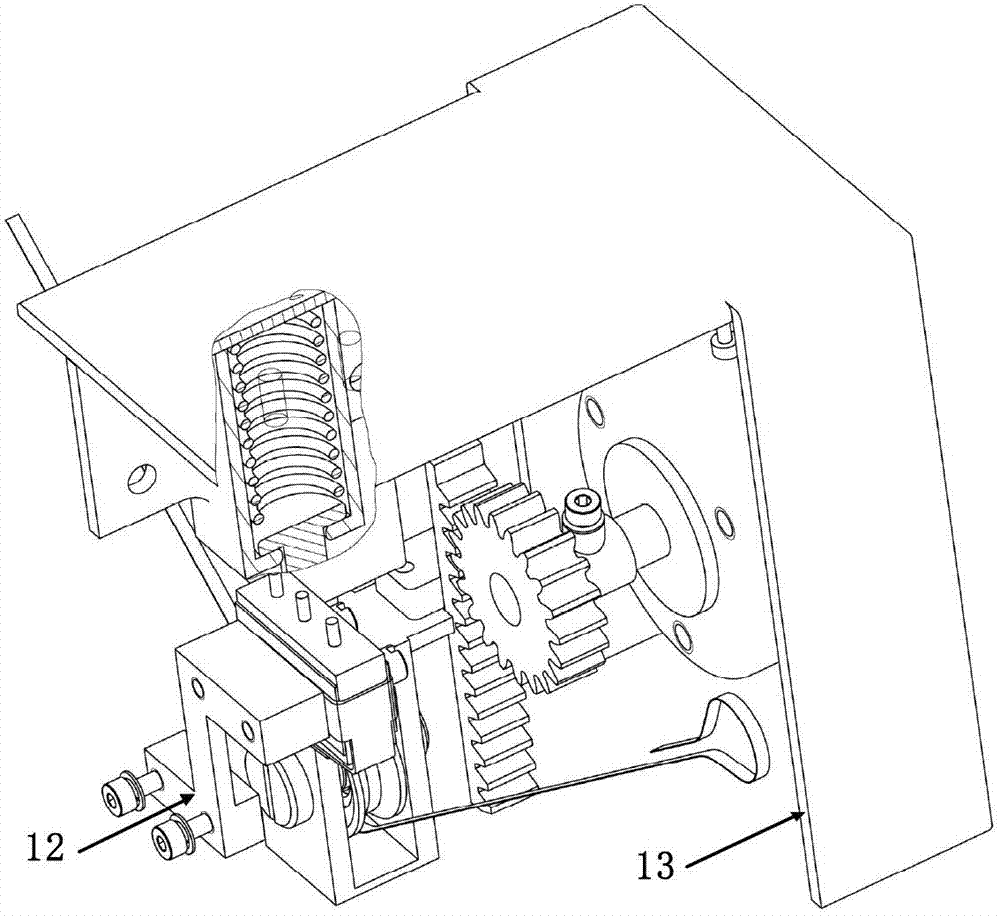

[0027] Such as figure 1 As shown, this embodiment provides a cable tension on-orbit monitoring device for a spacecraft, including an angular position sensor, a rack and pinion transmission assembly, a micro switch, a mounting sleeve, a compression spring, a push rod, and a roller assembly, Wherein, the rope rotates around the roller assembly, and the roller assembly is compressed by the compression spring through the push rod, the compression spring is arranged in the installation sleeve, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com