Heavy crane for ships and underwater installation technology

An installation process and heavy-duty technology, applied in the direction of cranes, etc., can solve the problems of large number of supports, affecting the installation plane accuracy of the ring gear of the crane, poor versatility, etc., and achieve the effect of improving work efficiency and crane installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

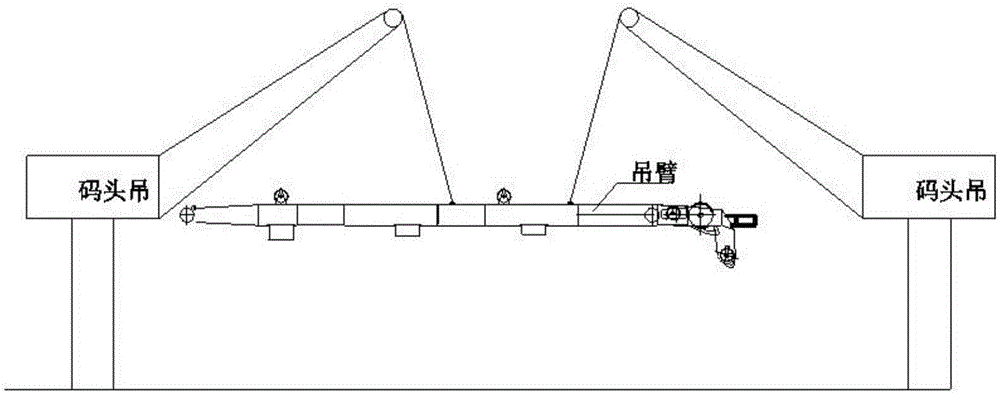

[0041] The present invention is a marine heavy crane and underwater installation process,

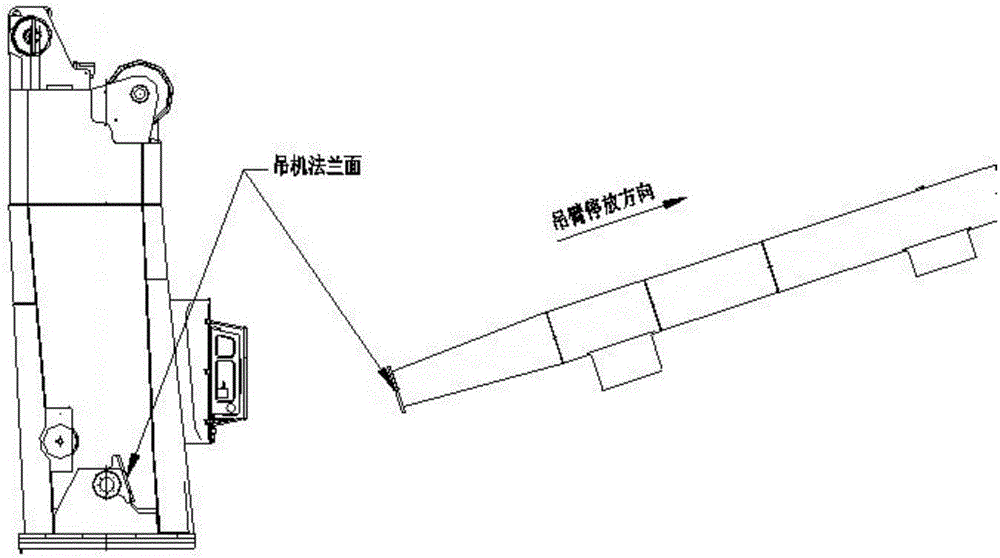

[0042] A heavy-duty marine crane includes a support, a tower body, a boom, a wire rope, and a hook. The lower end of the tower body is connected with the support, the boom is connected with the flange surface of the tower body, one end of the steel wire rope is connected with the boom, and the other end is connected with the hook.

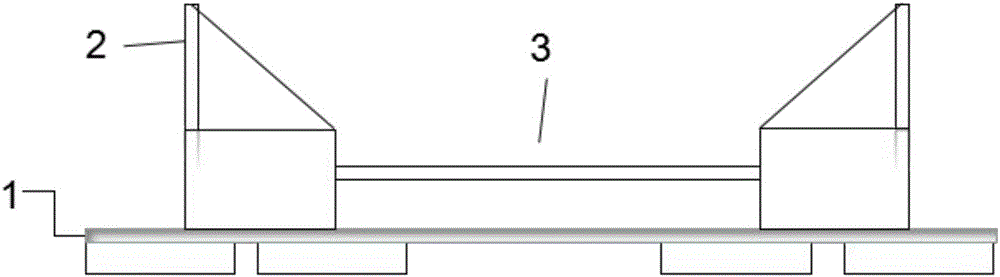

[0043] like figure 1 As shown, the support includes a central seat 1, several adjustable auxiliary seat groups 2, and an electric device 3. The central seat 1 is placed on the installation station and includes two opposite adjustable auxiliary seats. The auxiliary seat group 2 is arranged on the central seat 1 , and the electric device 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com