Aircraft engine compartment air inlet flue fairing

An engine compartment and air intake technology, which is applied to the power plant on the aircraft, the components of the aircraft power plant, and the combustion of the intake port of the power plant, etc. The complex shape and other problems of the road can achieve the effect of meeting the installation and use requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

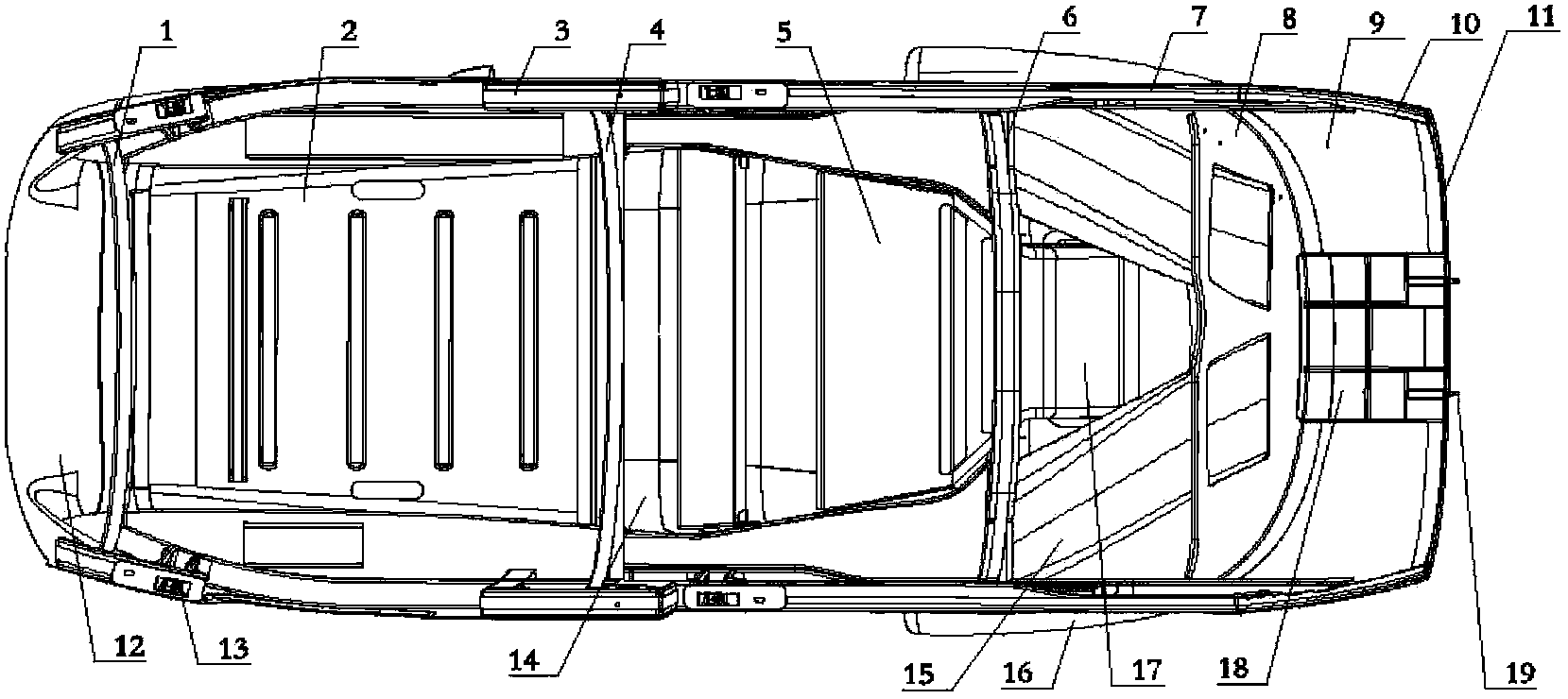

[0018] YF aircraft nacelle inlet fairing adopts a new shape design, and the new shape has better aerodynamic performance. For the specific structure of the intake fairing of the engine compartment, see figure 1 .

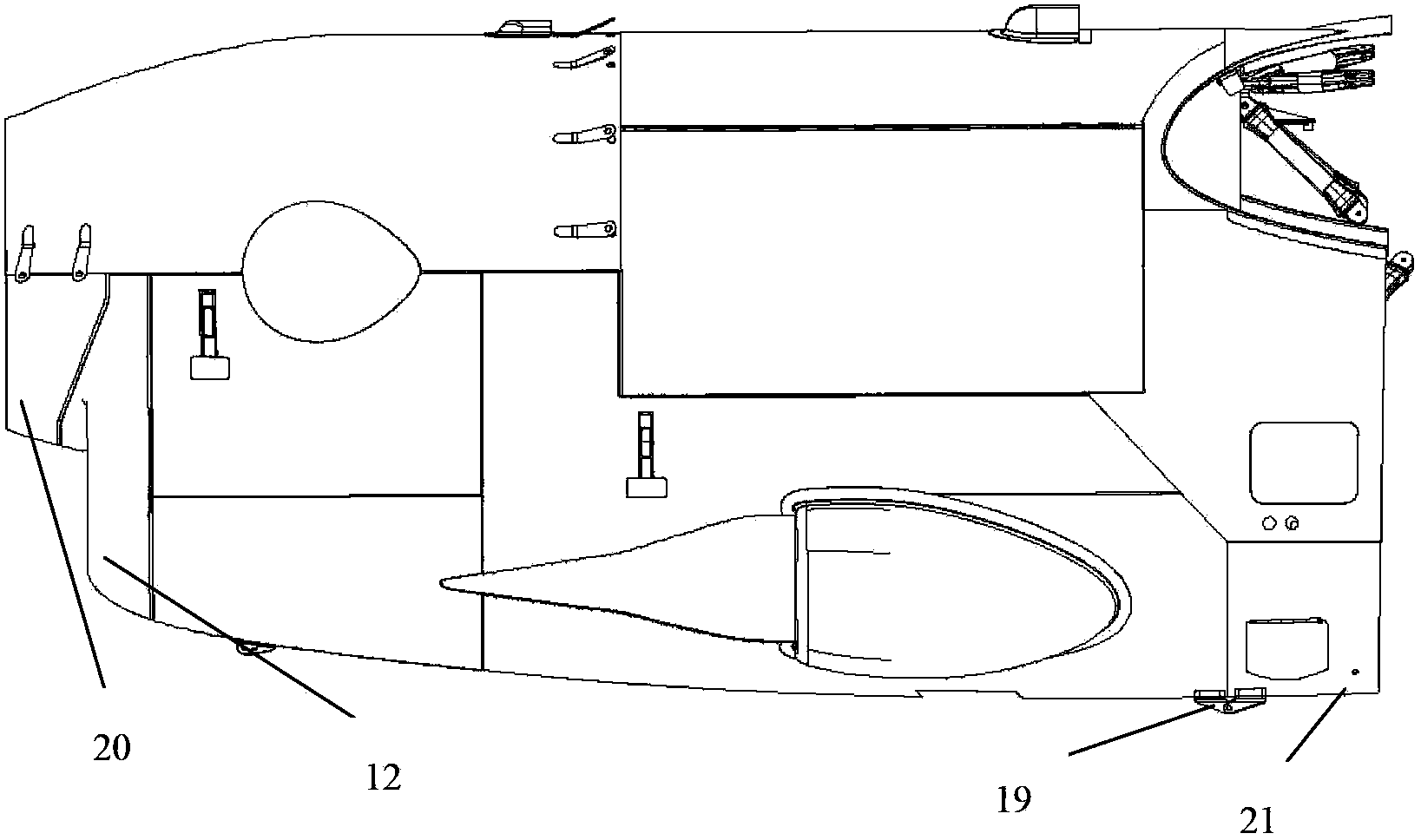

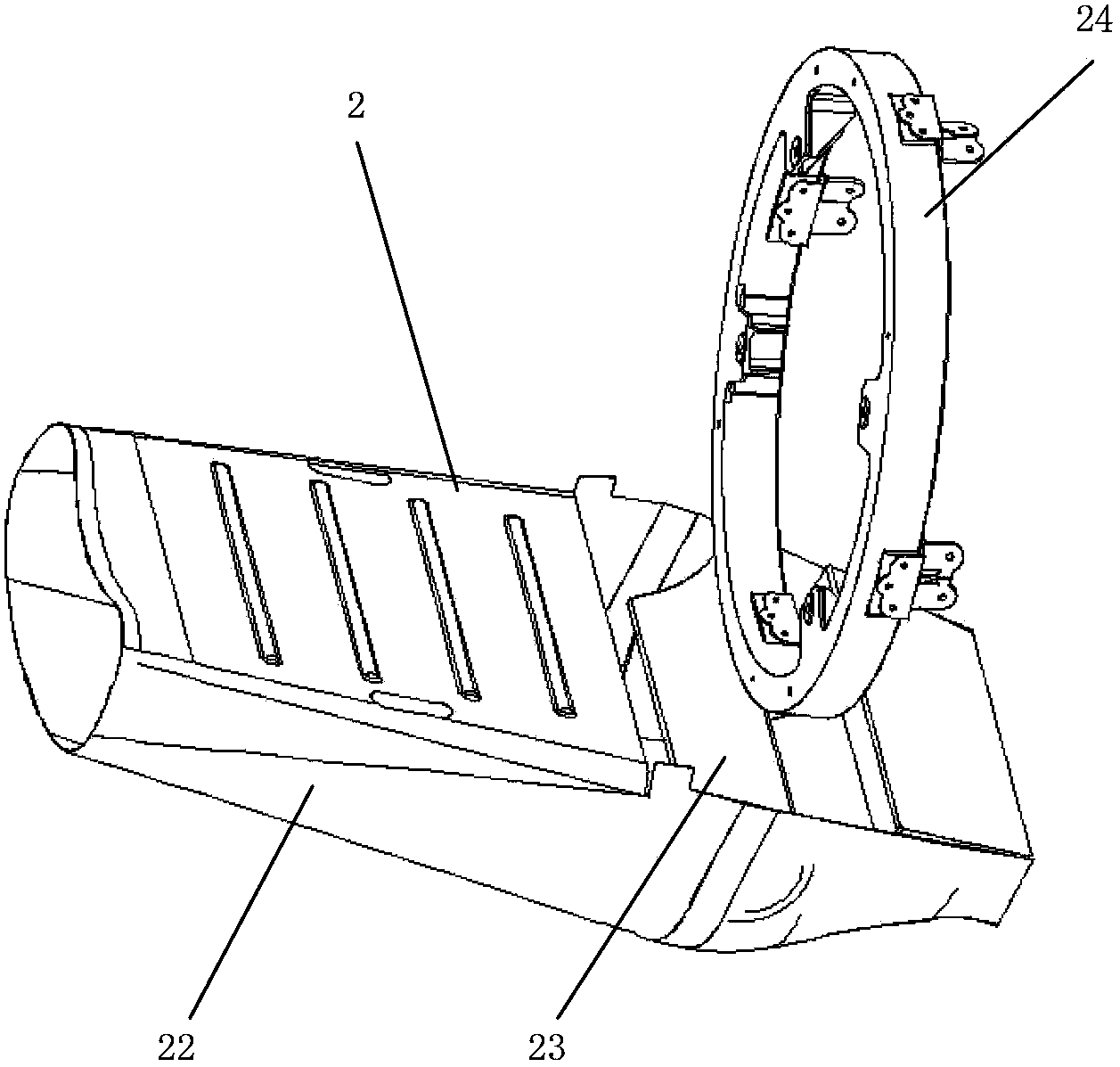

[0019] The engine intake fairing is the largest movable cover in the engine compartment, and is mainly used for engine inspection and maintenance. The main structure includes 3 frames 1, the upper cover plate of the air inlet 2, the sealing belt 3, the front sealing plate 4, the screen assembly 5, 9 frame 6, the upper stringer 7, 10 frame 8, the skin assembly 9, and the oblique beam 10 , end frame 11, rear lip 12, lock assembly 13, engine air intake assembly 14, lubricating oil air intake assembly 15, lubricating oil radiator fairing 16, ice and snow separation channel assembly 17, joint reinforcement 18, connection Parts such as joint 19. Among them, the sealing belt 3 is designed as a rubber material; the front sealing plate 4, the screen assembly 5, the frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com