Anti-loose connecting pair

A connecting pair and anti-loosening technology, applied in the direction of connecting components, threaded fasteners, screws, etc., can solve the problems of high maintenance cost, time-consuming and labor-intensive, easy to loosen, etc. The effect of strong anti-loosening ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the present invention, the present invention will be described in detail below in conjunction with specific drawings.

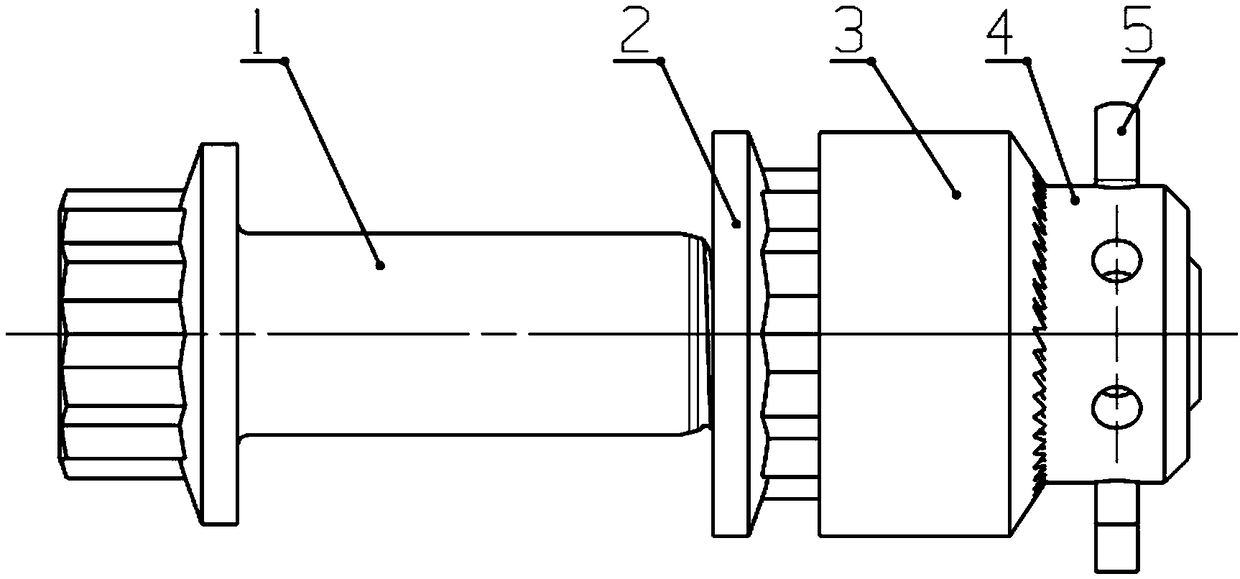

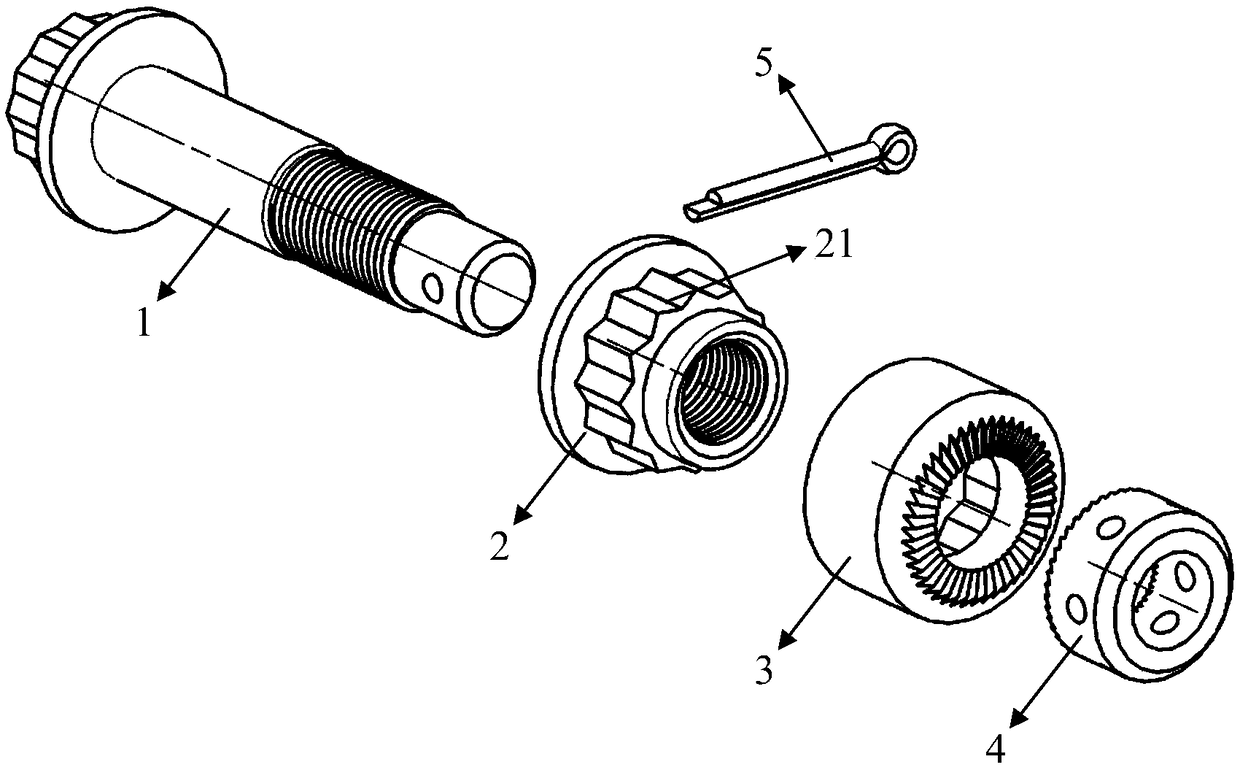

[0019] The anti-loose connection pair provided by the present invention is such as Figure 1-2 As shown, it includes a bolt 1, a nut 2, a sleeve body 3, a ring body 4 and a pin body 5.

[0020] Bolt 1 ( Figure 3-6 ) is the main load-bearing part, and the rod body includes a polished rod part 11, a threaded part 12 and a stop part 13 in sequence. The polished rod portion 11 is the main load-bearing part of the bolt 1 , and its diameter is one specification larger than the major diameter of the threaded portion 12 , so it can bear the relatively large shear force exerted by the connecting structure. The circular arc at the connection part of the head 14 of the bolt 1 and the polished rod 11 is strengthened by cold rolling to increase the bonding force between the head 14 and the polished rod 11, realize the fatigue resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com