Tapered roller bearing with positioning groove in outer ring end face

A tapered roller bearing and outer ring end face technology, applied in the field of auto parts, can solve the problems of poor surface stress, slippage, insufficient bearing interference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

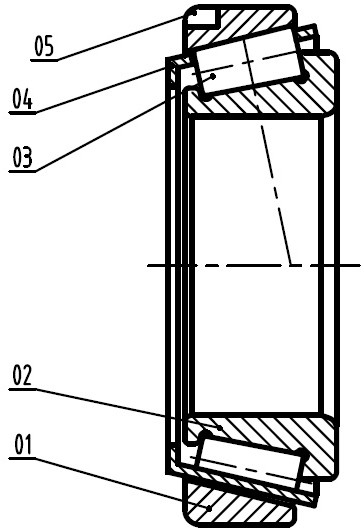

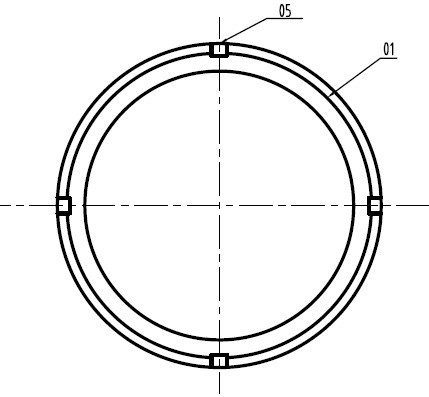

[0023] Such as Figure 1 to Figure 3 shown. An embodiment of a tapered roller bearing with a positioning groove on the end surface of the outer ring of the present invention, which is composed of an outer ring 01, an inner ring 02, a rolling body 03 and a cage 04, wherein the inner ring 02, the rolling body 03 and the cage 04 is a conventional tapered bearing part. The outer ring 01 is also the same as the outer ring of a conventional tapered bearing except for the keyway 05.

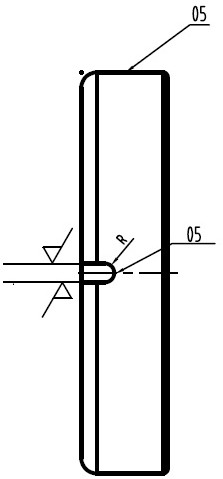

[0024] The keyway 05 is arranged at the joint of the outer diameter of the end surface of the outer ring 01, starting from the large end surface of the outer ring 01 and extending axially along the outer diameter. Keyway 05 is a semi-closed structure with a single round head flat keyway. There are four key grooves 05, which are evenly distributed along the outer diameter and the circumferenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com