Gas extraction drilling orifice device and operating method thereof

A gas extraction and orifice technology, which is applied in gas discharge, safety devices, mining fluids, etc., can solve the problems of coal and gas outburst accidents, high gas concentration, affecting the safety production efficiency of coal mines, etc., to achieve reliable sealing and prevent gas The effect of an overrun accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

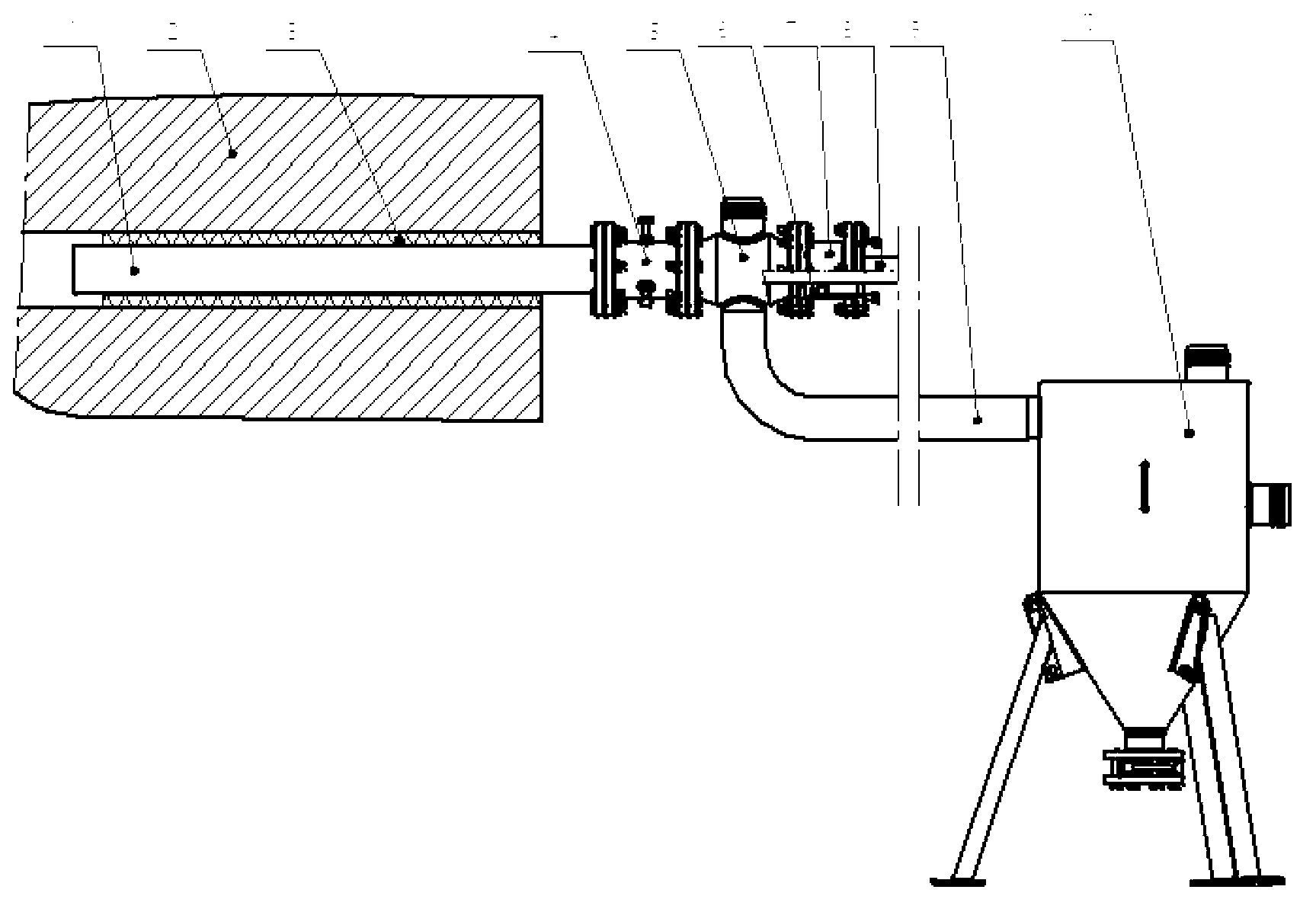

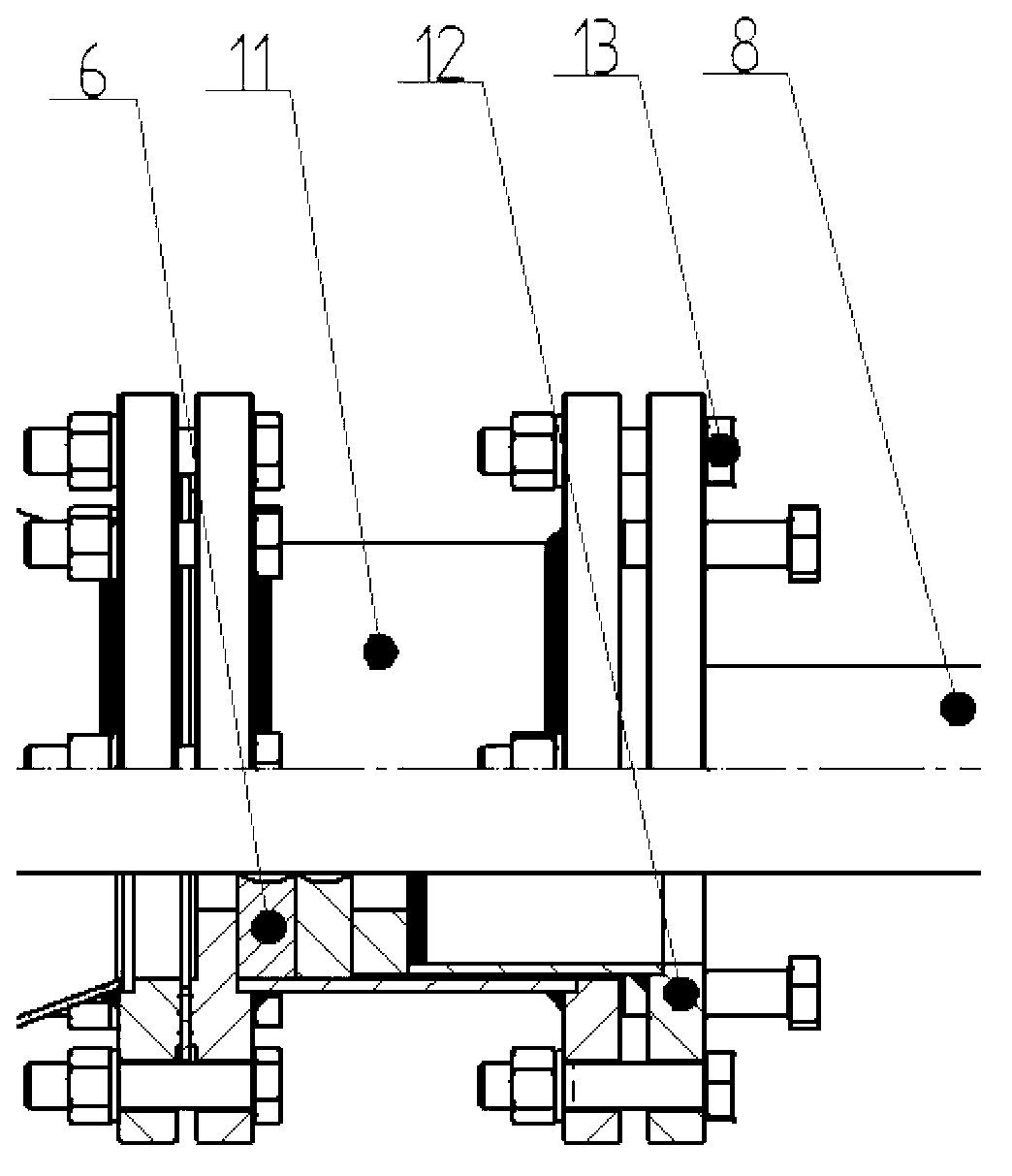

[0022] see figure 1 , a gas drainage drilling orifice device, including an orifice pipe 1, an outburst prevention pipe 4, a cross 5, a sealing assembly 6, an orifice sealing pipe 7, a rubber hose 9, and a gas-water separator 10, wherein the outburst prevention The pipe 4, the cross 5 and the orifice sealing pipe 7 are connected by flanges in turn, and are fixed and sealed on the borehole wall together with the orifice pipe 1. The gas-water separator 10 is connected with the lower port of the cross 5 through the rubber pipe 9.

[0023] Before use, ream the drilled hole to the specified diameter and depth, lower the orifice pipe 1 into the hole, and fill the space between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com