Track-type natural gas pipeline valve

A natural gas pipeline and rail-type technology, which is applied to sliding valves, valve devices, engine components, etc., can solve the problems of inconvenient operation, large power and space, and high safety risks, and achieves a small occupied area, easy operation, and stability factor. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

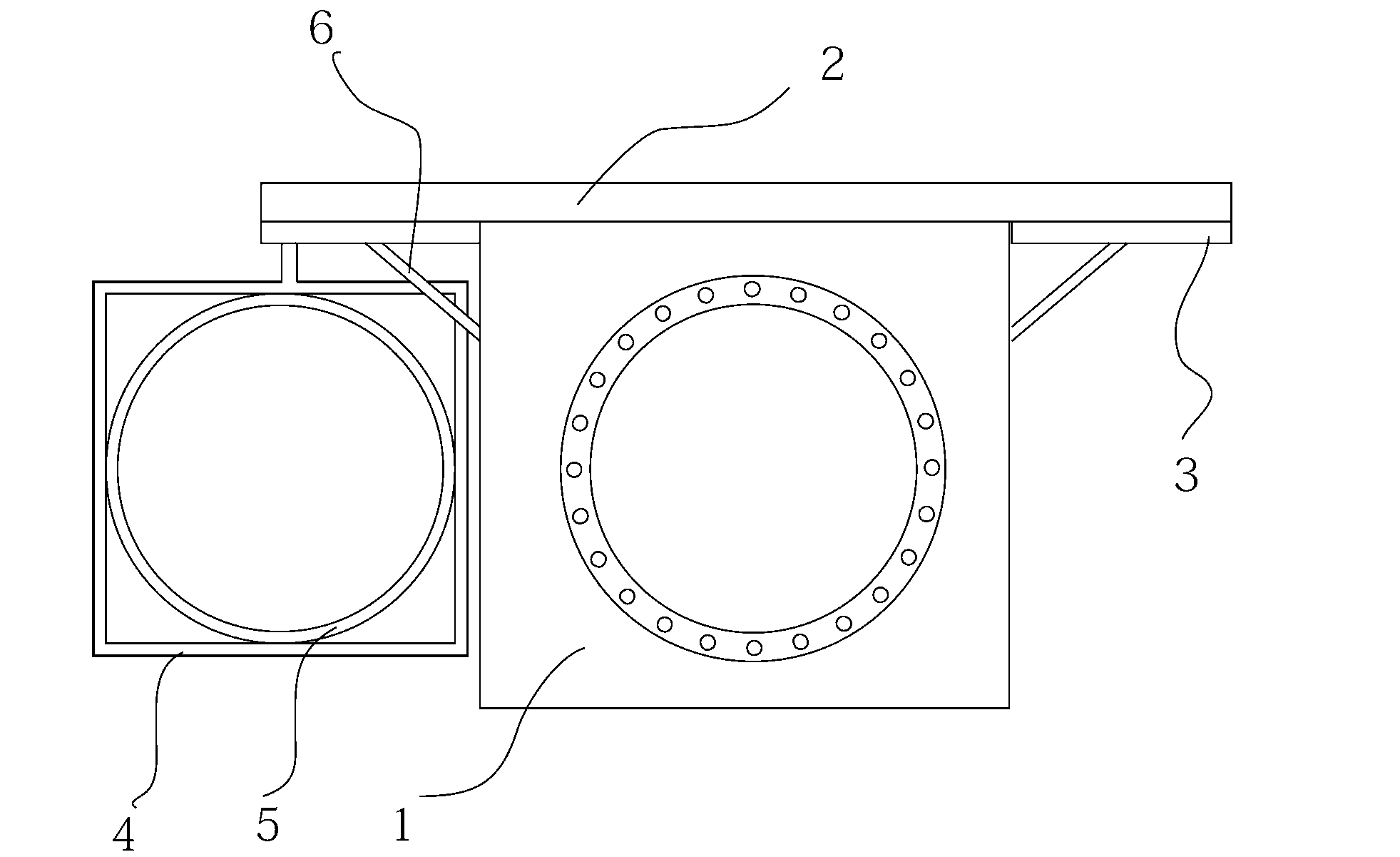

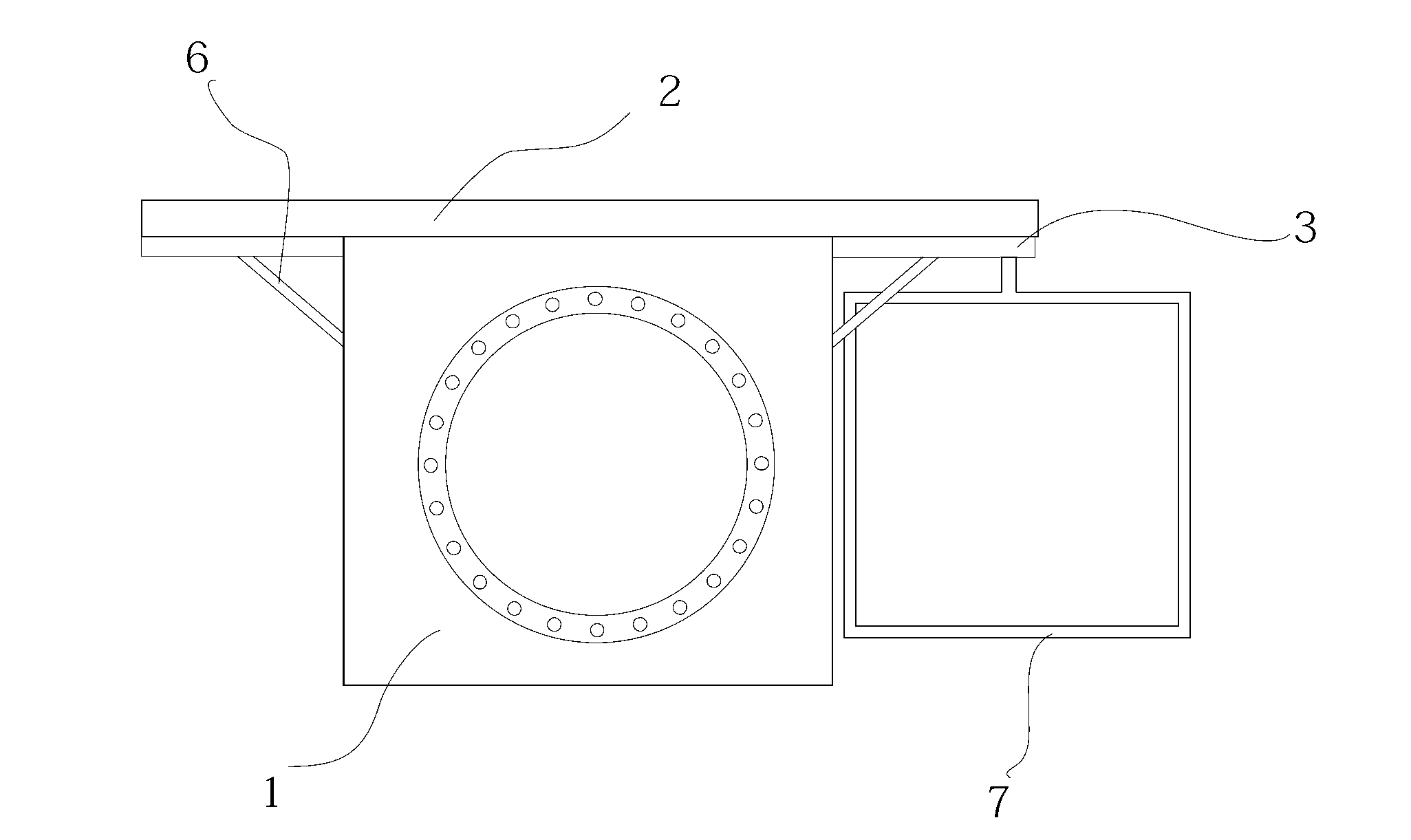

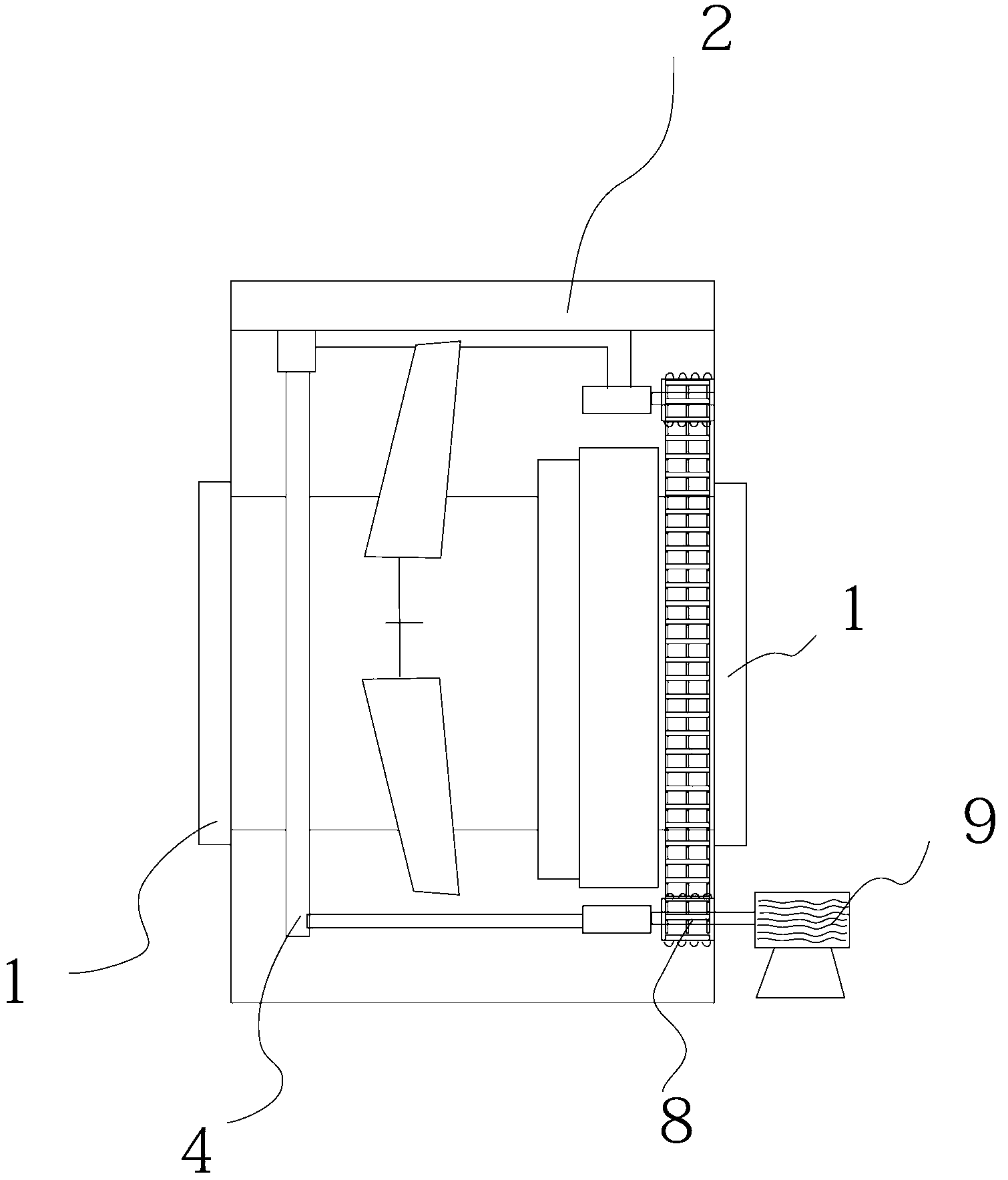

[0014] Such as figure 1 , 2 As shown, a track-type natural gas pipeline valve includes a valve seat 1, a top beam 2 is installed above the valve seat 1, and a suspended guide rail 3 is installed below the top beam 2, and the guide rails 3 are sequentially below A valve plate 7 and a frame 4 are fixed; a valve ring 5 is installed in the middle of the frame 4 .

[0015] In order to keep the guide rail 3 moving during the movement and make it difficult to desolder, a fixed arm 6 is installed at the joint between the valve seat 1 and the guide rail 3 .

[0016] when working, such as Figure 1-2 As shown, the guide rail drives the valve plate and frame 4 to slide from left to right. First, the valve plate 7 leaves the valve seat 1 and continues to move forward, and then the valve ring 5 enters the valve seat 1, which realizes the process from closing to opening of the valve. The surface of the valve ring 5 is provided with a circle of rubber pads, which can effectively prevent n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com