Bioregenerative particle and powder mixed burner

A bio-regeneration and burner technology, which is applied in the combustion, combustion and ignition, and combustion methods of solid fuels, can solve the problems of difficult popularization and utilization, high cost, and high combustion cost of biomass-regenerated fuels, so as to facilitate regular cleaning and save use. , the effect of conducive to burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

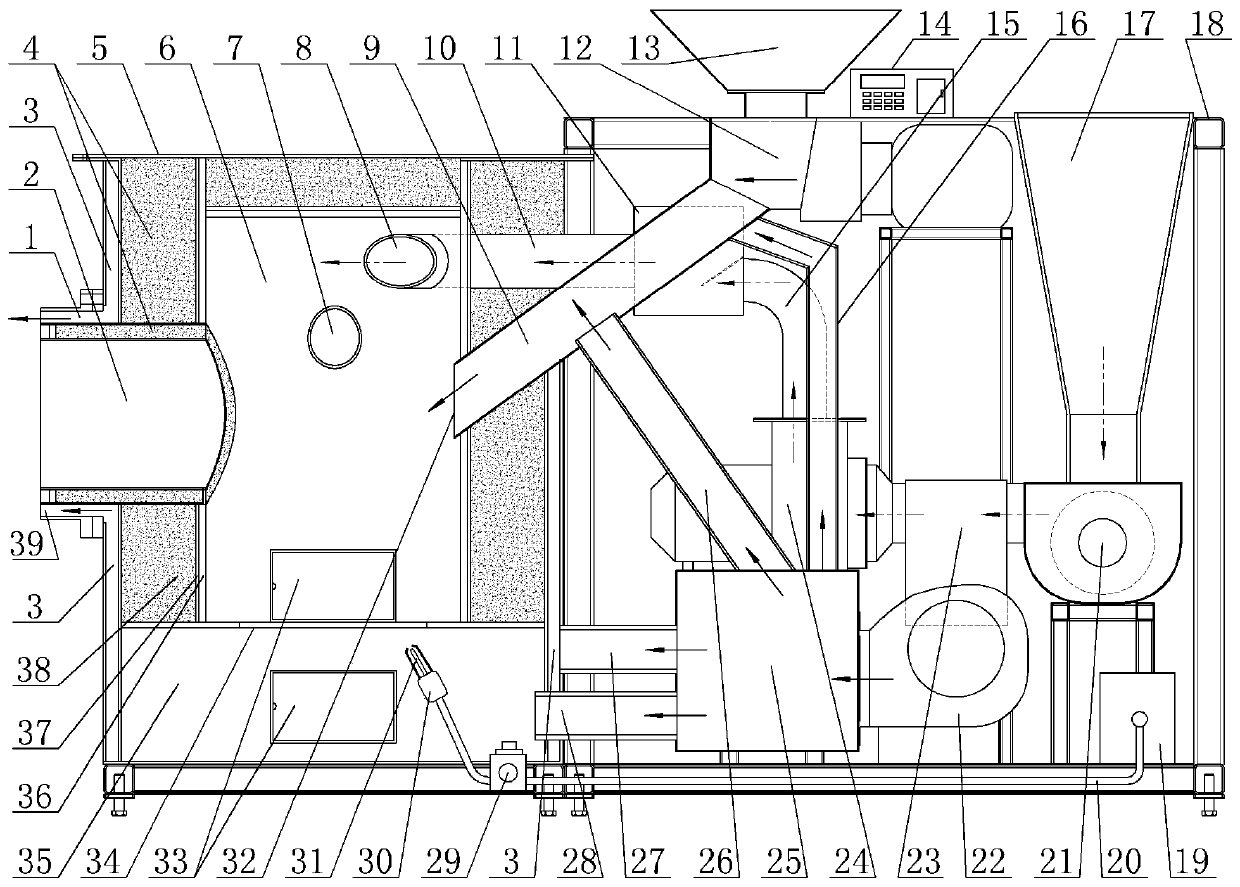

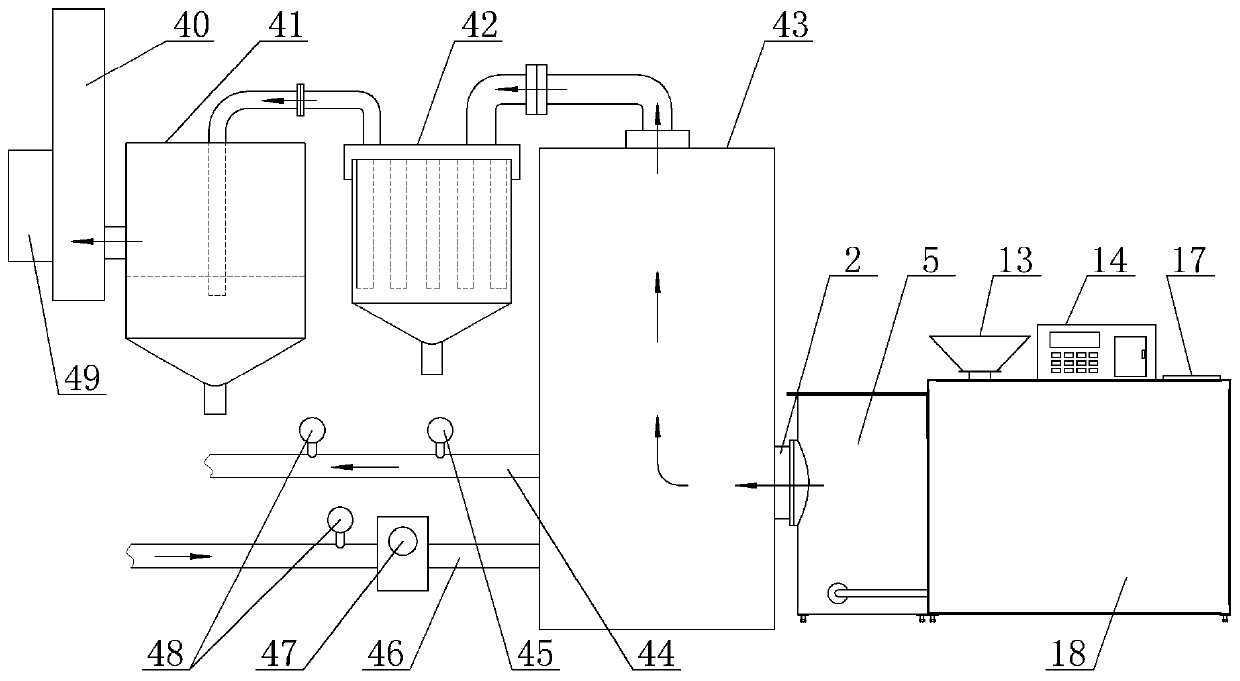

[0032] The biological regeneration particle and powder mixed combustion machine has a frame 18, and the frame is equipped with a combustion tank, an air supply mechanism, a particle material feeding mechanism, a powder material feeding mechanism, and an ignition mechanism;

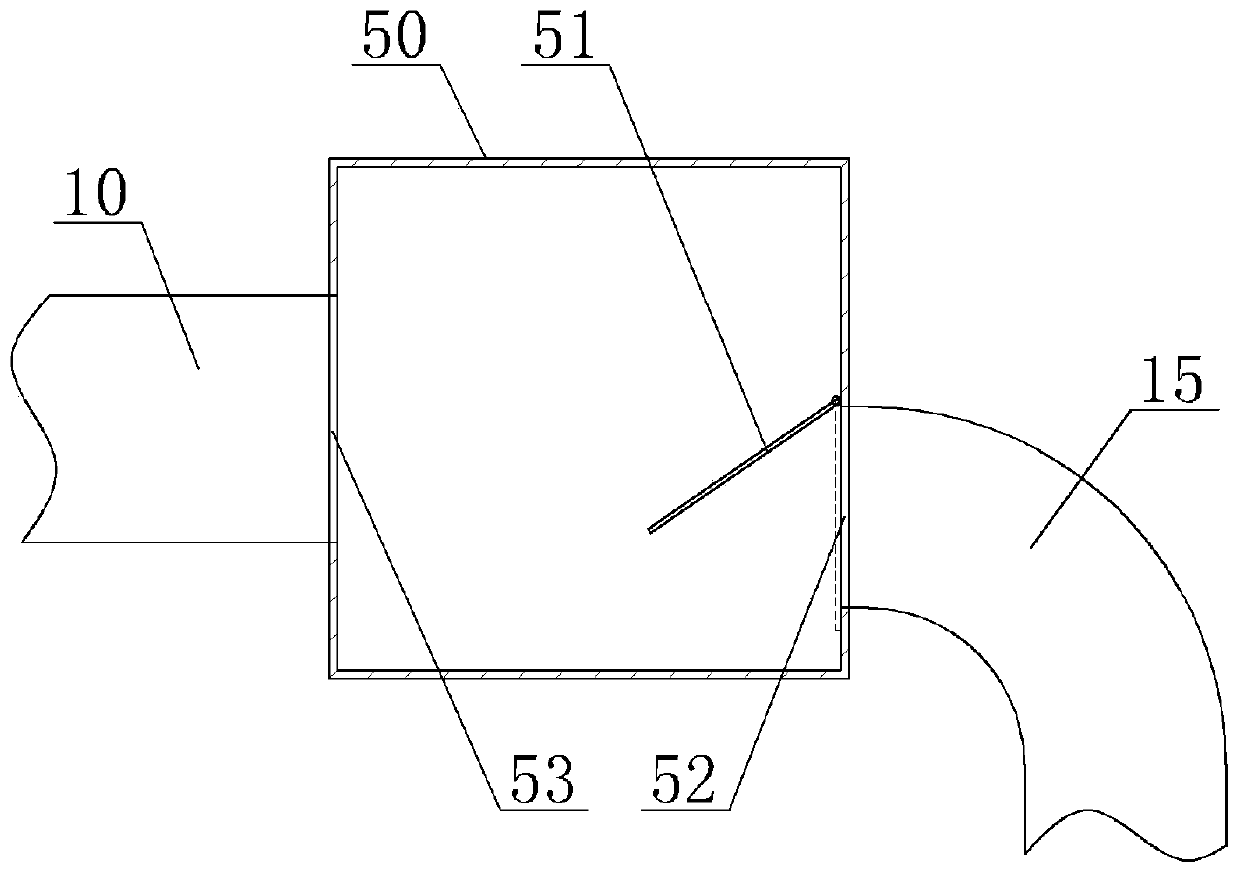

[0033]Described combustion tank has cylindrical tank body 5, and the outer wall of tank body is provided with tank wall interlayer 3, is provided with fire grate 34 in the tank body, and the tank interior space below fire grate is ash chamber 35, and the tank interior above fire grate The space is the combustion chamber 6, and the inner wall of the tank around the combustion chamber is provided with a refractory insulation layer 4, and the tank body on the upper part of the combustion chamber is provided with a powder inlet 8, which is arranged along the direction of the tank wall, and is used to make the incoming The powder rotates along the inner wall of the tank through the feeding inertia, which is bene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com