Bushing closing-up processing method

A processing method and bushing technology, which are applied in the field of small load-bearing lock bushing closing processing, can solve problems such as lock pin squeezing, and achieve the effect of good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

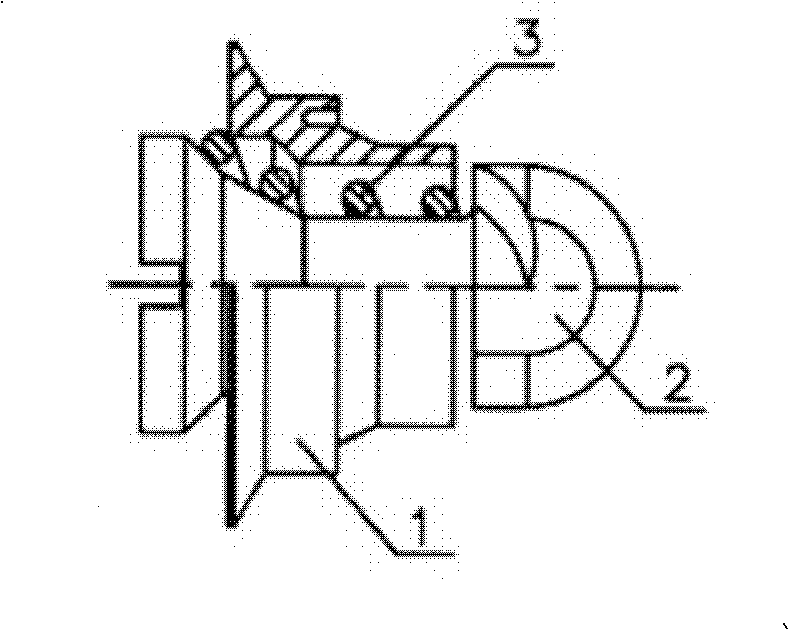

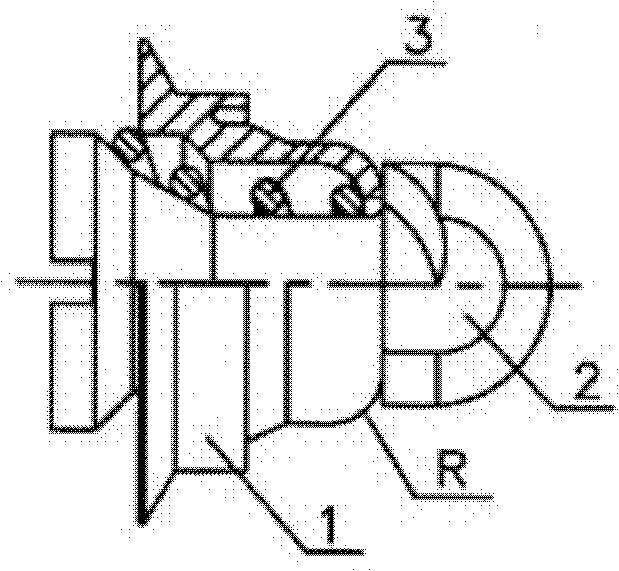

[0009] Attached below Figure 1~3 To further describe the present invention, one of the main components of the bearing lock is the upper lock body structure, such as figure 1 As shown, the end of the bushing 1 is required to be closed during assembly (such as figure 2 center R), so that the spring 3 is enclosed in the bushing 1, and the assembly of the lock body is completed; now, rollers are generally used on lathes for closing processing, and the processing method of one-time closing forming is adopted, and the lock pin 2 is easy to be closed during forming. squeezed, such as figure 2 shown.

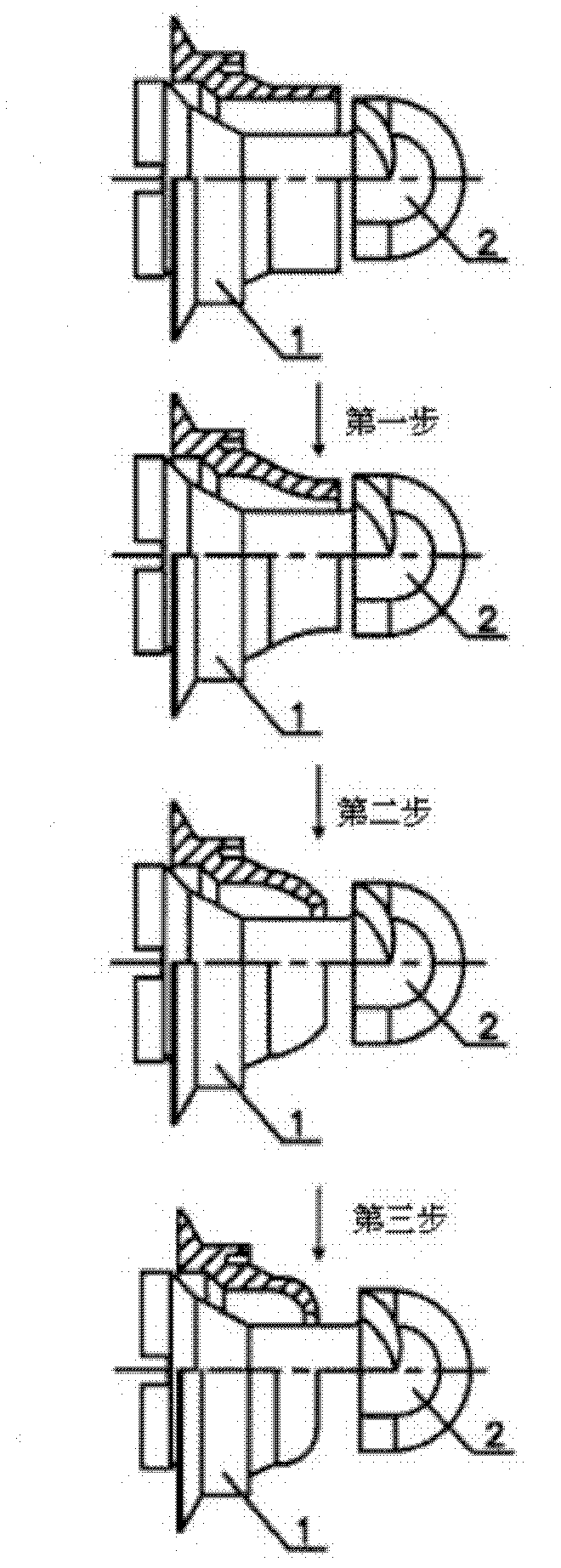

[0010] The present invention is to change the one-time closing forming into the three-time closing forming processing method, and its specific implementation steps are shown in image 3 (spring 3 is not shown); this scheme makes bushing 1 have a process of pre-deformation, re-deformation, and final deformation in the closing-up forming process. In the pre-deformation stage, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com