Non taking soil drawing hole method for construction of sinking pile for prestressed pipe pile or prefabricated square pile

A technology of prestressed pipe piles and construction methods, which is applied to sheet pile walls, foundation structure engineering, buildings, etc., can solve the problems of high cost and large pile counterforce, and achieve lower project cost, lower pile sinking force, and ensure The effect of engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

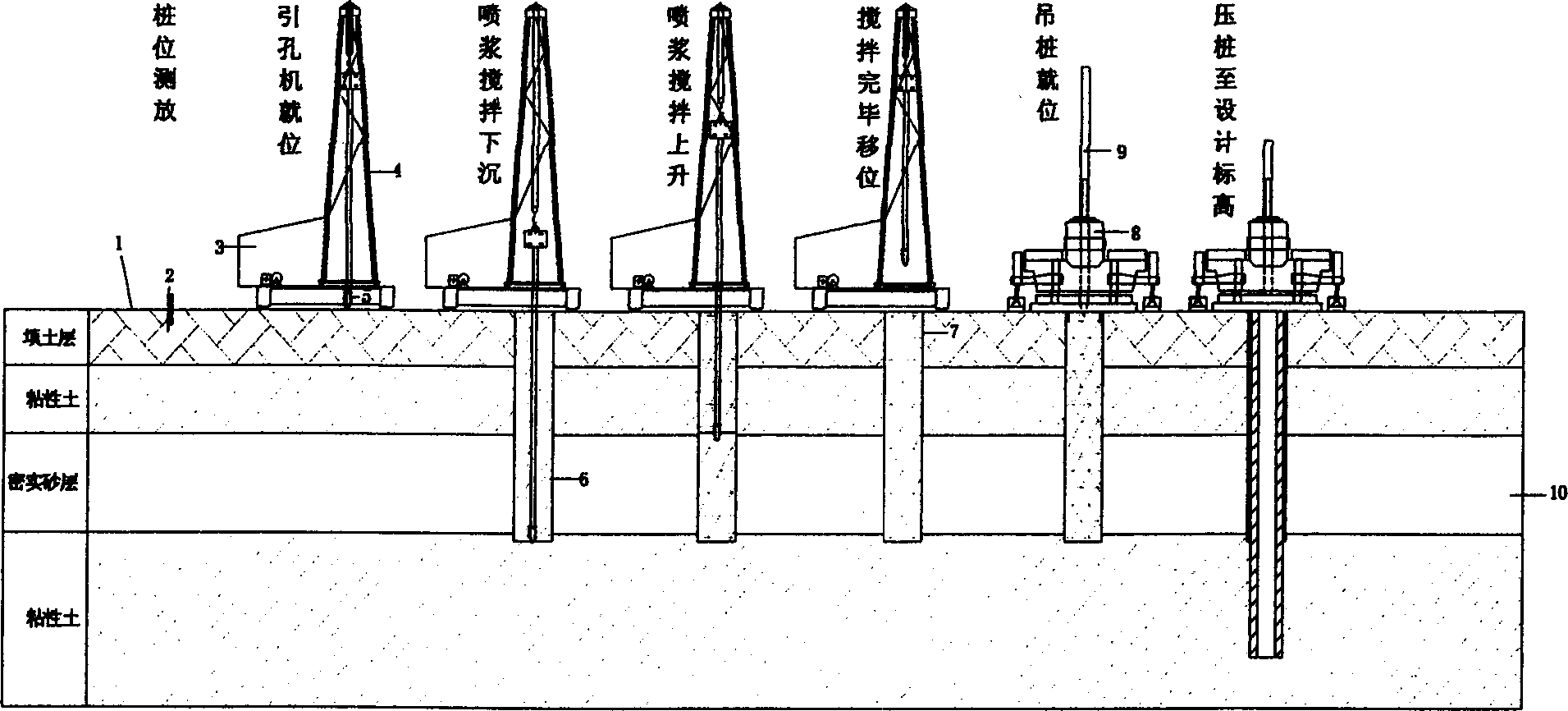

[0025] As can be seen from the accompanying drawings, a non-borrowing approach prestressed pipe pile or prefabricated square pile pile sinking construction method, the steps are:

[0026] A. Pile position measurement: measure and place the pile positions according to the design drawings, each pile position is driven into the ground with a bamboo stick with a length of 20 cm and a width of 1-1.5 cm, paint the top of the bamboo stick exposed to the ground, and It should be flat with the ground surface to avoid damage or displacement when people walk or the pile driver moves. For the convenience of review and measurement, certain control points should be arranged according to the axis and protected with cement mortar;

[0027] B. Lead hole construction: use SMW construction method machine or high-power deep mixing machine to carry out lead hole construction at the pile position. The depth of the pilot hole is determined according to the burial depth of the sand layer, and it is ...

Embodiment 2

[0030] As can be seen from the accompanying drawings, a non-earth-borrowing prestressed pipe pile or prefabricated square pile pile sinking construction method, the work steps are:

[0031]A. Pile position measurement: Measure and place the pile positions according to the design drawing. Each pile position is driven into the ground with a bamboo stick with a length of 20 cm and a width of 1 cm. The surface is flat to avoid damage or displacement when people walk around. For the convenience of review and measurement, the sliding axis is set as the central axis control point every 10 to 15 meters and protected with cement mortar;

[0032] B. Leading hole construction: use high-power deep mixing machinery, use P032.5 ordinary Portland hydrochloric acid cement and bentonite as the components of the slurry, during the drilling process of the drilling rig, the slurry should be kept continuous and uniform, and the cement should be based on the weight of the soil. 15-18% mixed, benton...

Embodiment 3

[0035] As can be seen from the accompanying drawings, a non-borrowing approach prestressed pipe pile or prefabricated square pile pile sinking construction method, the steps are:

[0036] A. Pile position measurement: Measure and place the pile positions according to the design drawing. Each pile position is driven into the ground with a bamboo stick with a length of 20 cm and a width of 1.5 cm. The surface is flat to avoid damage or displacement when people walk around. For the convenience of review and measurement, the central axis control point is made along the intersection of the axis and protected with cement mortar;

[0037] B. Pilot hole construction: use high-power deep mixing machinery and use P032.5 ordinary Portland hydrochloric acid cement and bentonite as the components of the slurry. During the drilling process of the drilling rig, the slurry supply should be kept continuous and uniform, and the cement should be 10% of the soil weight. ~12% mixed, bentonite with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com