Method for planting prestressed pipe pile at one step

A technology for prestressed pipe piles and planting piles, which is applied in sheet pile walls, buildings, infrastructure projects, etc., can solve the problems of cross construction and large pile driving reaction force, save project cost and improve the friction resistance around piles. , the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

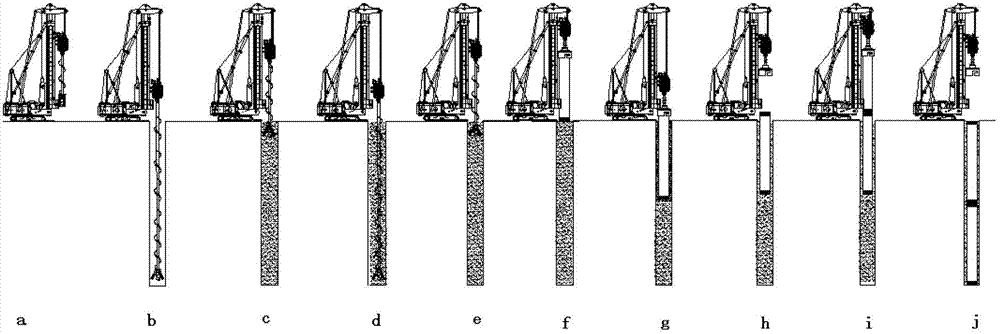

[0023] The one-time pile planting method of the prestressed pipe pile of the present invention is specifically described in conjunction with the accompanying drawings.

[0024] The disposable pile planting method of prestressed pipe pile of the present invention comprises the following steps:

[0025] a. Drilling rig in place: First, the construction site must be leveled and compacted to ensure roads, water, and electricity. According to the design intention, personnel and mechanical equipment such as pile machines and theodolites must be equipped. Operators must be familiar with geological conditions. Then accurately determine the pile position on the flat and compacted construction site, and make obvious marks, including the mark after the hole is formed, and the pile driver will go to the designated pile position and align it in place.

[0026] b. Pilot hole operation: start the pile machine, and sink the drill pipe along the guide frame to the design depth. The pile machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com