Powder remover

A technology of de-powdering and stripping, applied in beehives, applications, beekeeping, etc., can solve the problems of crowding and crowding, affecting the normal entry and exit efficiency of bees, etc., and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

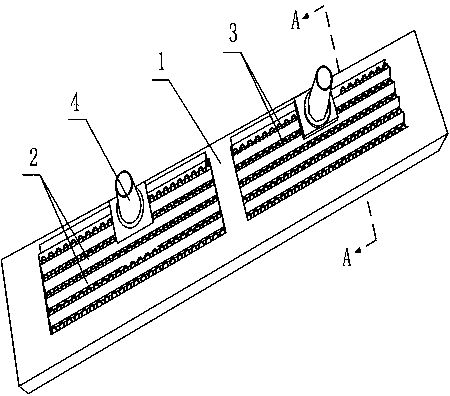

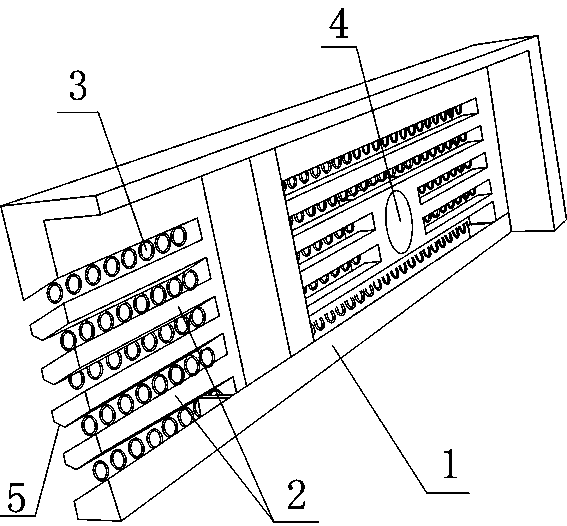

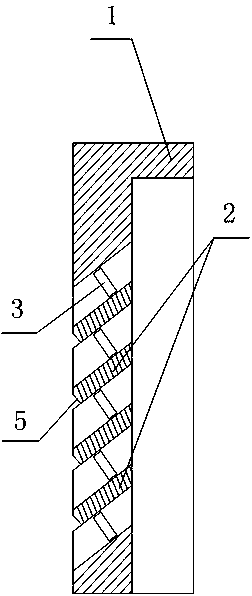

[0026] Such as Figure 1 to Figure 3 As shown, the powder remover of the present invention includes a powder remover plate body 1, and a plurality of spacers 2 are arranged in the powder remover plate body 1, and between the powder remover plate body 1 and the spacer bars 2, and adjacent Powder removal holes 3 are arranged between the spacers 2, and a one-way channel 4 is provided on the powder remover plate body 1, and the spacer bars 2 are arranged from the outside to the inside of the powder remover plate body 1, and are arranged obliquely from bottom to top; Between two adjacent spacers 2, the top edge of the spacer 2 located below is higher than the bottom edge of the spacer 2 located above. The angle between the spacer 2 and the horizontal plane is 30°. The one-way channel 4 has a smooth outer surface. On the outer side of the spacer 2 , a slope 5 that is not parallel to the outer side is cut; the powder removal hole 3 is perpendicular to the surface of the spacer 2 . ...

Embodiment 2

[0029] On the basis of Embodiment 1, the included angle between the spacer 2 and the horizontal plane in this embodiment is 60°. Good results can also be obtained.

Embodiment 3

[0031] On the basis of Embodiment 1, the included angle between the spacer 2 and the horizontal plane in this embodiment is 45°. An included angle of 45° is the optimal solution. This angle can ensure that the spacer 2 blocks light, and at the same time, it can satisfy pollen sliding down the surface of the spacer 2 and prevent pollen from staying on the spacer 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com