Mounting structure of car-coupler shock absorber

A technology of buffer device and installation structure, which is applied to traction devices, transportation and packaging, railway car body parts, etc., can solve the problem of not being suitable for installation of WILLISON couplers, and achieve the effect of facilitating inspection and maintenance and preventing decoupling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

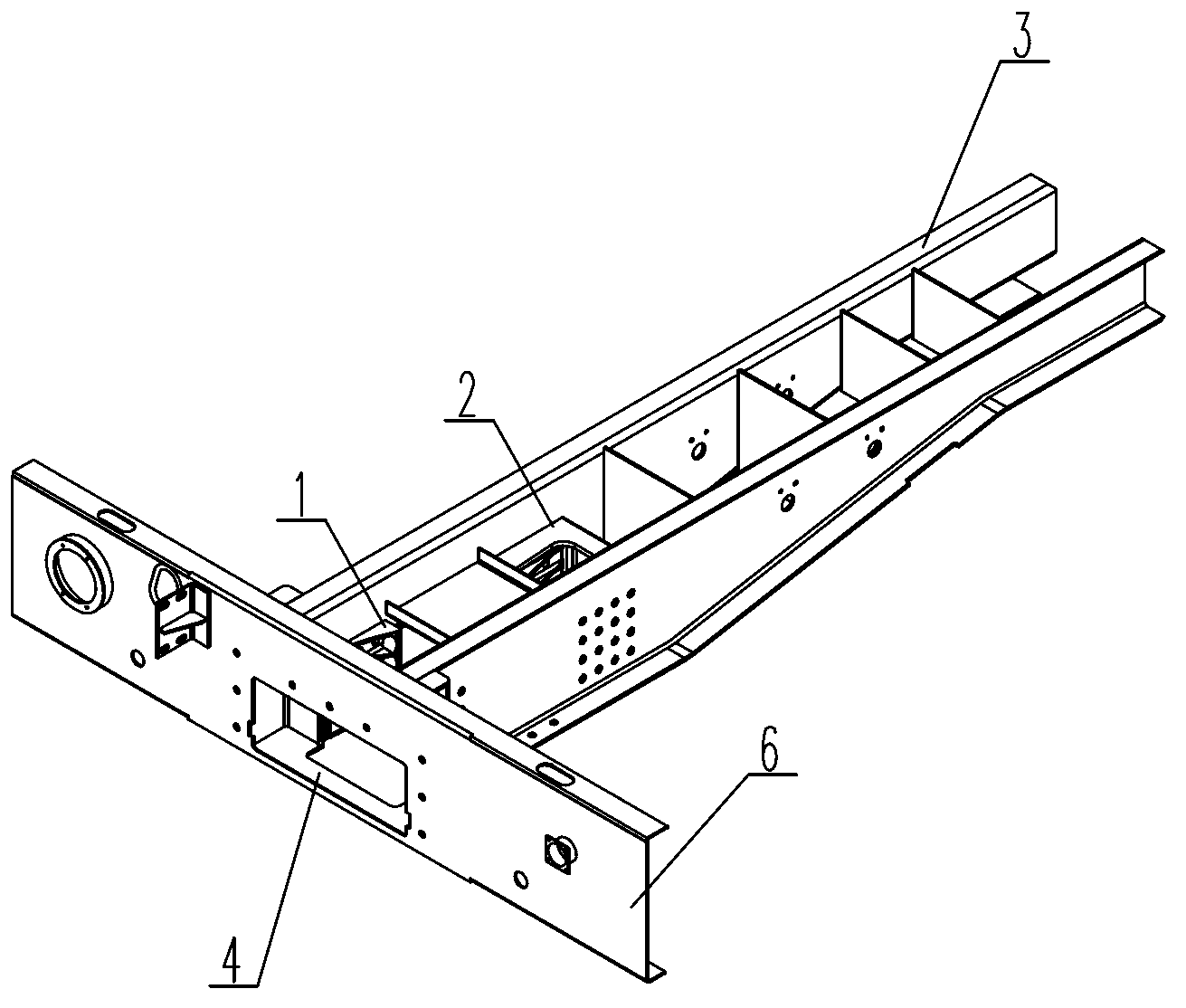

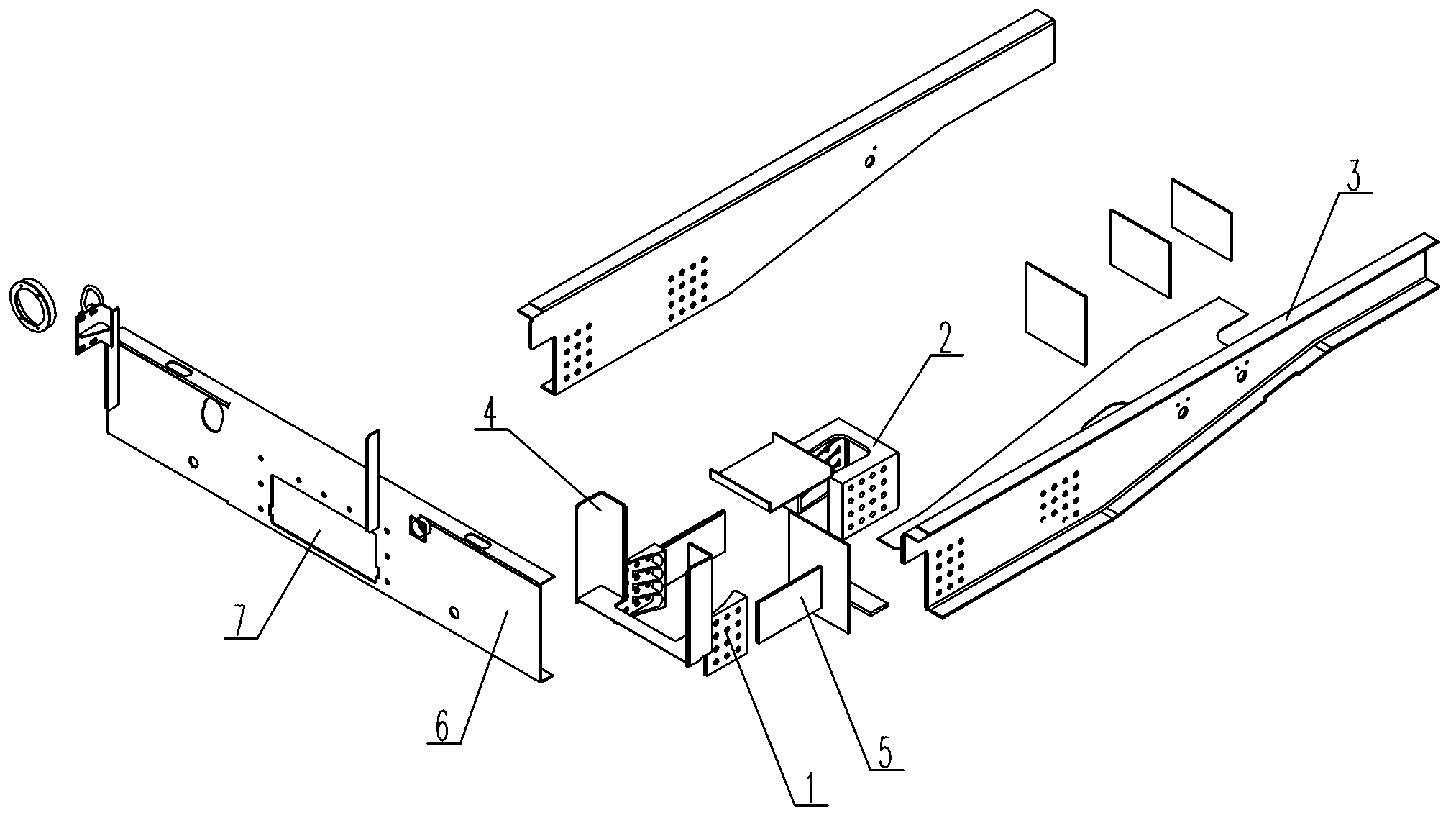

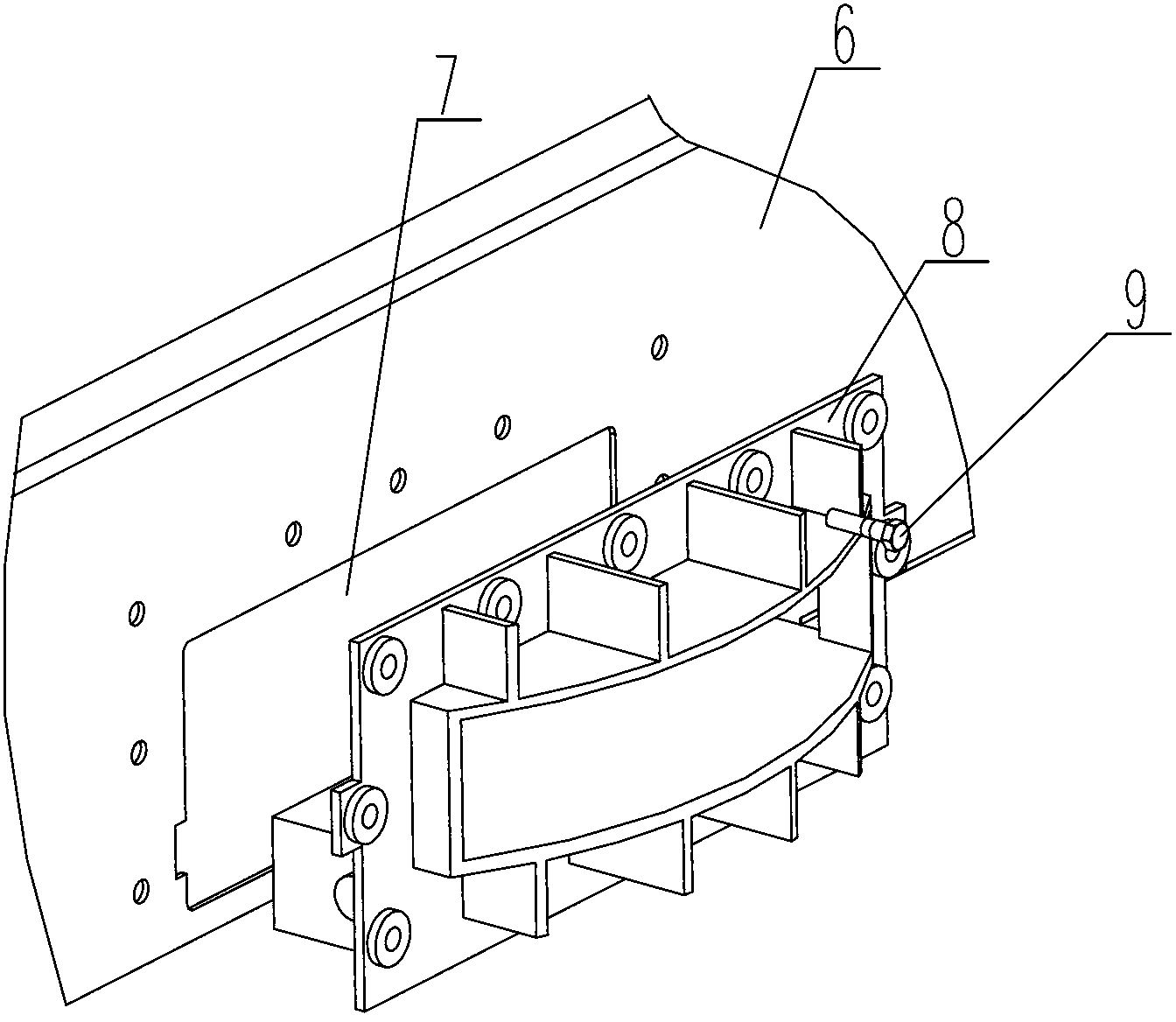

[0020] like figure 1 As shown, the coupler buffer device of this embodiment consists of: an impact seat, a front slave plate seat 1, a rear slave plate seat 2, a coupler frame 4, a rectangular opening 7 for the impact seat to be inserted and fixed is opened in the middle of the end beam 6, and the coupler frame 4 Welding and fixing on the inner side of the end beam 6 of the rectangular opening 7 and at the same time welding and fixing with the draw beam 3, the impact seat is fixed on the front end of the rectangular opening 7 in the middle of the end beam 6 through high-strength bolts 9, and the coupler restoring device is placed in the coupler frame 4, The two ends of the coupler recovery device are opposed to the inner wall of the coupler frame through the two side plates of the impact seat 8. The front plate base 1 and the rear plate base 2 are riveted and fixed on the traction beam 3 along the longitudinal direction. The buffer is placed between the front plate base and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com