Low-resistance and high-efficiency locking method and device for quick-opening door of pressure vessel

A pressure vessel, low-resistance and high-efficiency technology, applied in pressure vessels, fixed-capacity gas storage tanks, gas/liquid distribution and storage, etc., can solve problems such as unfavorable automatic control, unfavorable safe production, and locking hooks that cannot be locked. , to achieve low-resistance and high-efficiency fast-opening door locking method, facilitate automatic control, and reduce the effect of power input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

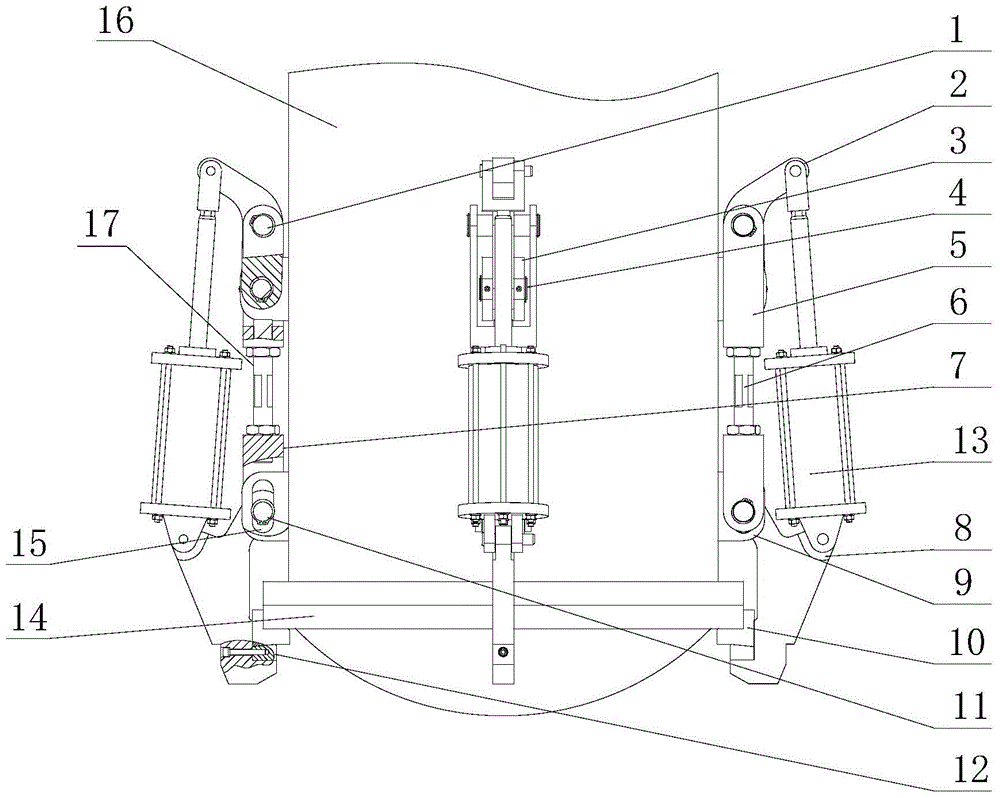

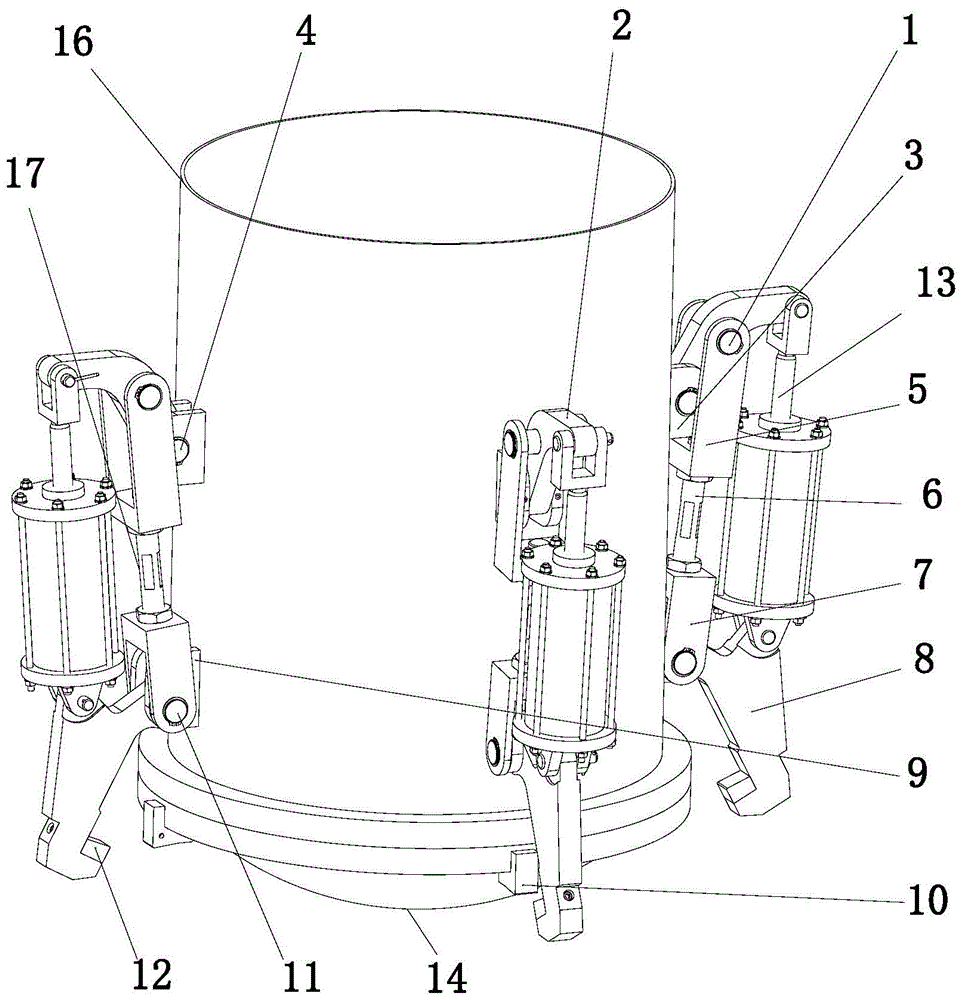

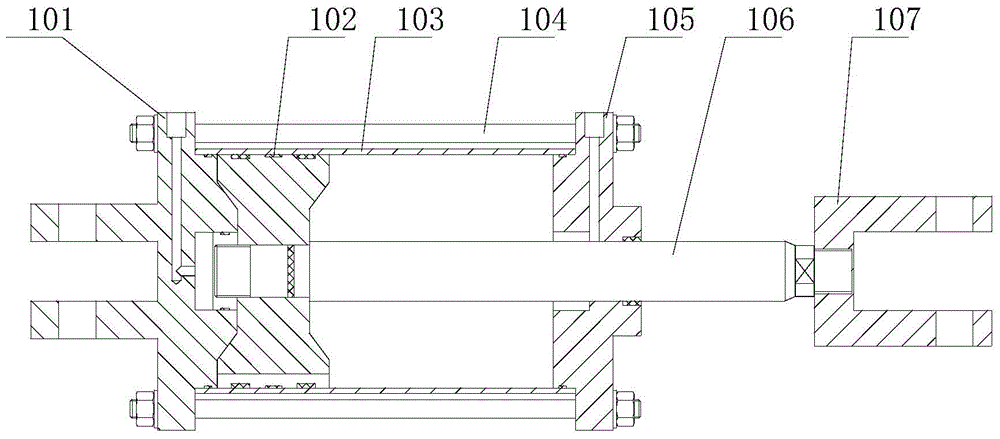

[0028] Example. The fast-opening low-resistance and high-efficiency locking method of the pressure vessel is characterized in that: a power source is used to expand the locking mechanism of the slider crank, and the locking hook connected to the locking mechanism of the slider crank is wound around the third pin shaft fixed on the pressure vessel. Rotate until it fits the inclined pad iron, and the inclined iron on the locking hook does not touch the inclined pad iron; as the power source continues to expand, the arm of the crank slider locking mechanism will drive the adjustable pull rod combination As the parts move, the locking hook is also lifted upwards until the bottom cover is locked; the centerlines of the first pin, the second pin and the third pin on the crank slider locking mechanism are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com