Adjustable open-circuit guide circuit

An adjustable and guide plate technology, applied in the direction of circuits, printed circuit components, electrical components, etc., can solve problems such as the difficulty of debugging and adjusting impedance values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The same components are denoted by the same reference numerals below.

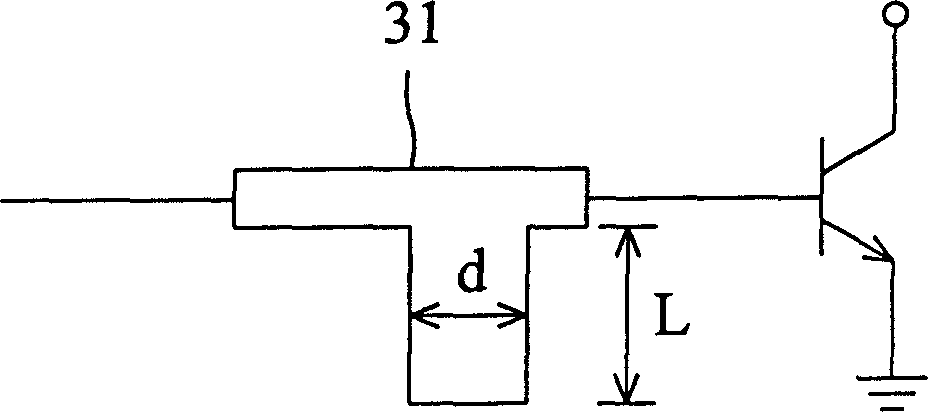

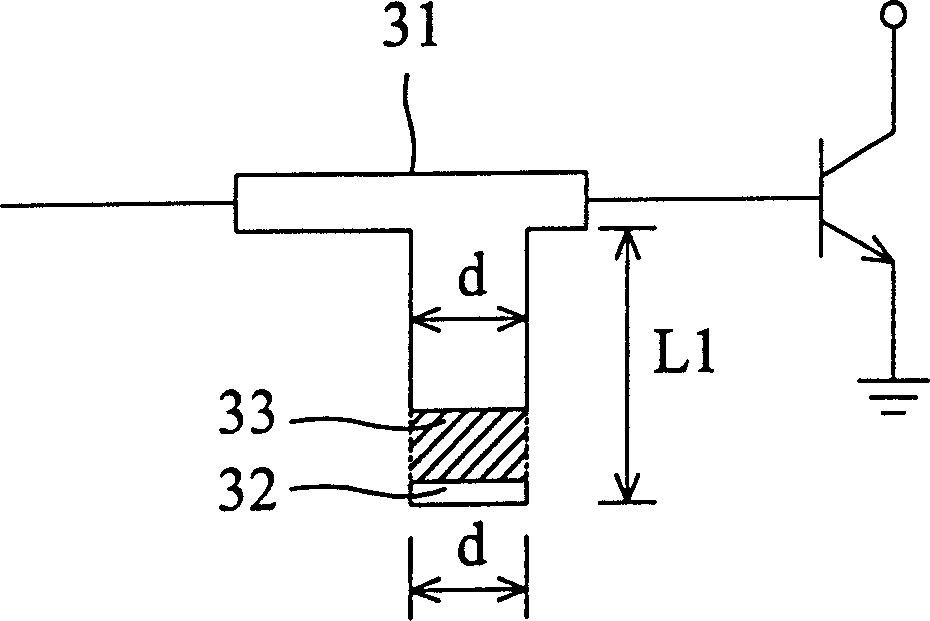

[0014] Figure 3a is a schematic diagram of an adjustable open flipper circuit configured monolithically in accordance with the present invention. exist Figure 3a Among them, a conductive metal sheet 32 whose length is equal to the width d of the open end of the open stud 31 is attached to the open end along with the open stud 31 during circuit layout. an appropriate distance below. When debugging, if it is found that the equivalent capacitance (or inductance) value required by the circuit must be increased, then if Figure 3a As shown, solder 33 is used to connect the metal piece 32 to the open end, so that the total length of the open end of the open guide plate changes from L to L1. Wherein, the solder can be any electrically conductive material such as tin, gold, copper, and the like. Additionally, if Figure 3b As shown, the preset conductive metal sheets can be a plurality of conducti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com