Anti-decoupling device for crane hook

An anti-decoupling and crane technology, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve problems such as easy scratches on the hands, inconvenient operation of the hook, and the anti-decoupling device cannot be in the normal working position, so as to avoid injuries , to ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Most of the existing anti-decoupling devices for hooks are simple baffles using springs. The efficiency of unhooking and hooking is low during use, and actual users will use multiple slings to lift items. However, too many slings or wire ropes affect The reset of the hook anti-decoupling device is prevented, so that the anti-decoupling device cannot be in the normal working position.

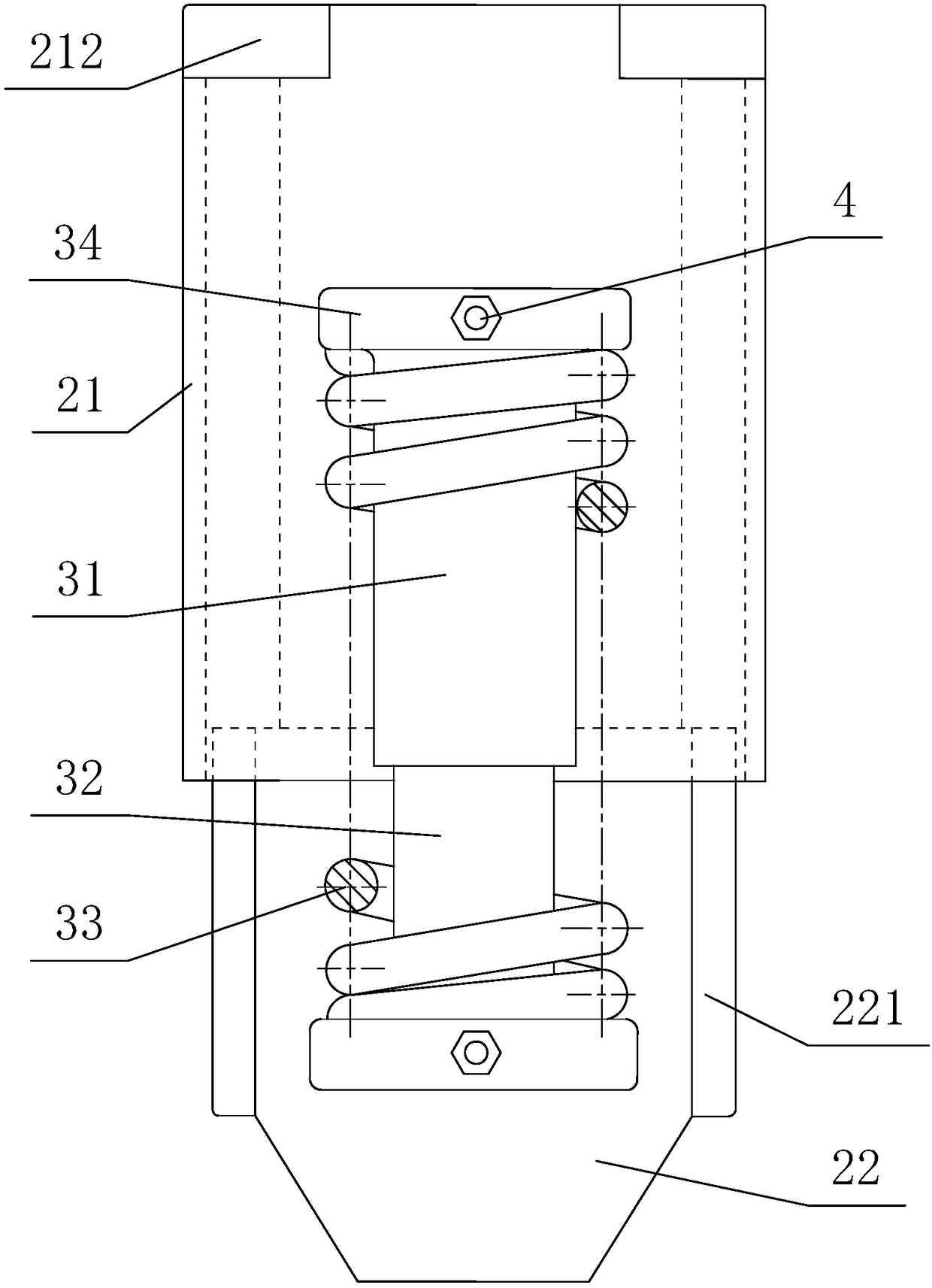

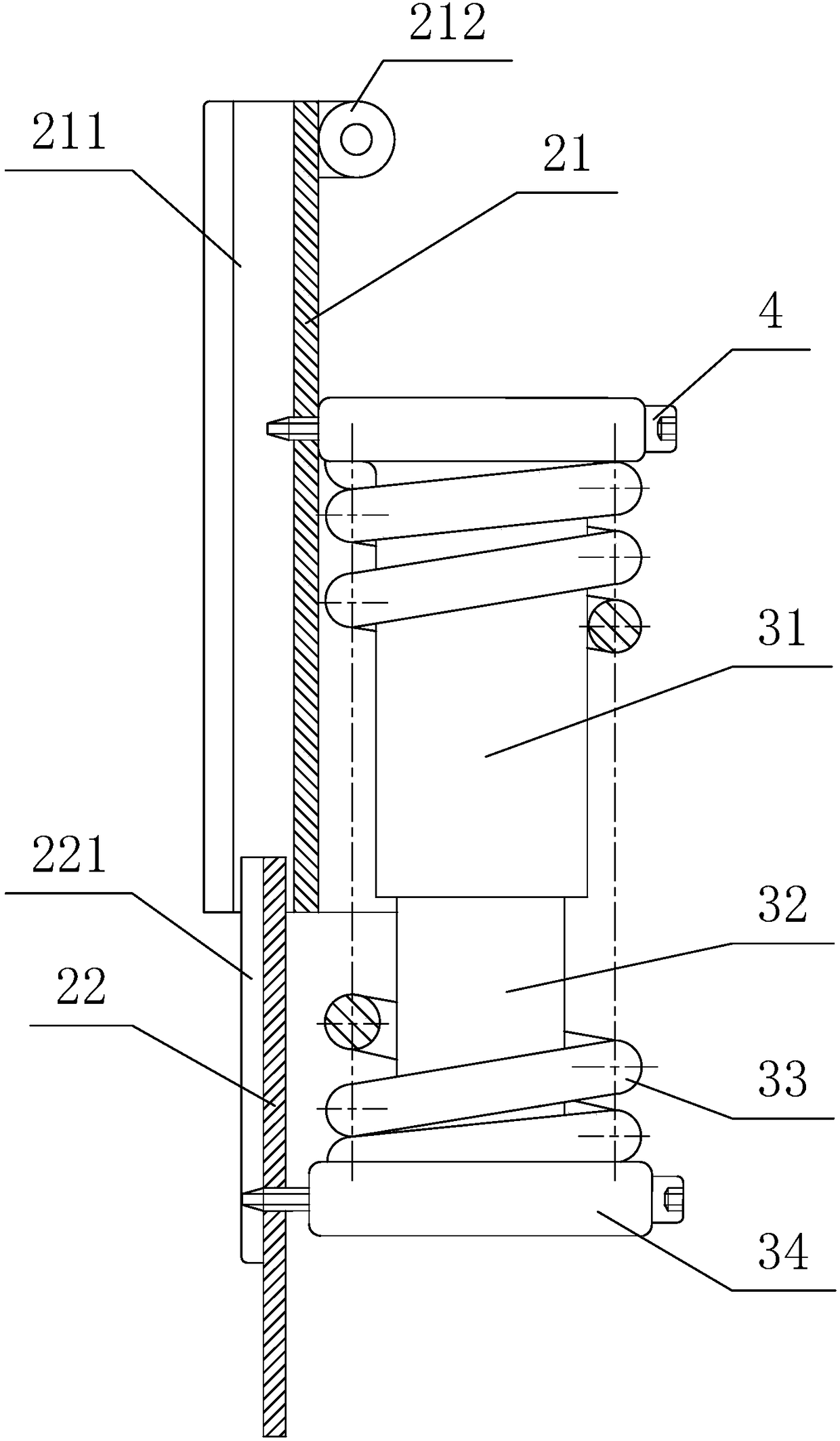

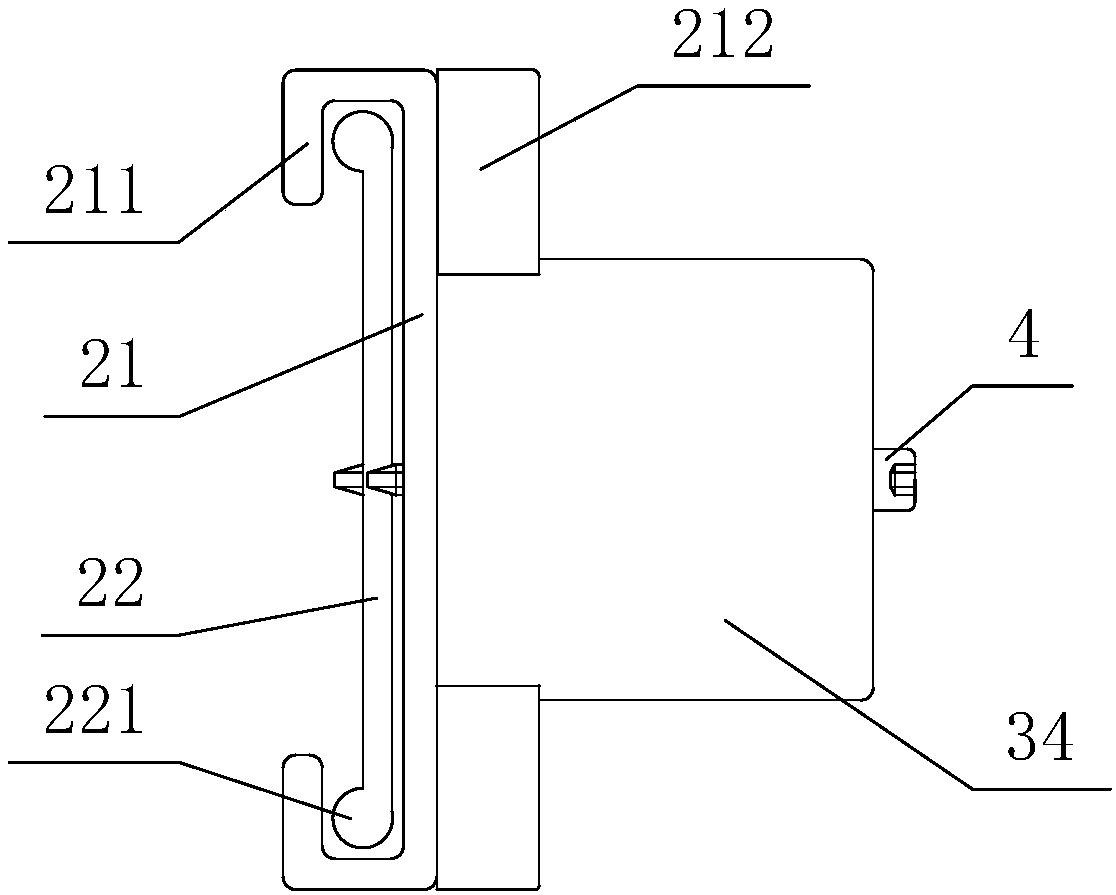

[0029] Aiming at the technical problems existing in the above-mentioned prior art, the embodiment of the present invention provides an anti-decoupling device for a crane hook, which includes an anti-decoupling plate hinged on the hook, and the hinge between the anti-decoupling plate and the hook is provided with a Torsion spring, the anti-dropping plate is composed of two baffles, the two baffles form a sliding connection through an elastic telescopic structure, and the elastic telescopic structure includes a telescopic telescopic piece and is located between the two ends of the telescopic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com