Intelligent double-layer ash discharging device

An ash unloading device and intelligent technology, which is applied in packaging, large containers, loading/unloading, etc., can solve problems such as poor unloading effect, blockage of the unloading port, cumbersome process, etc., and achieve strong practicability and promotion and application value , easy access, and easy mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

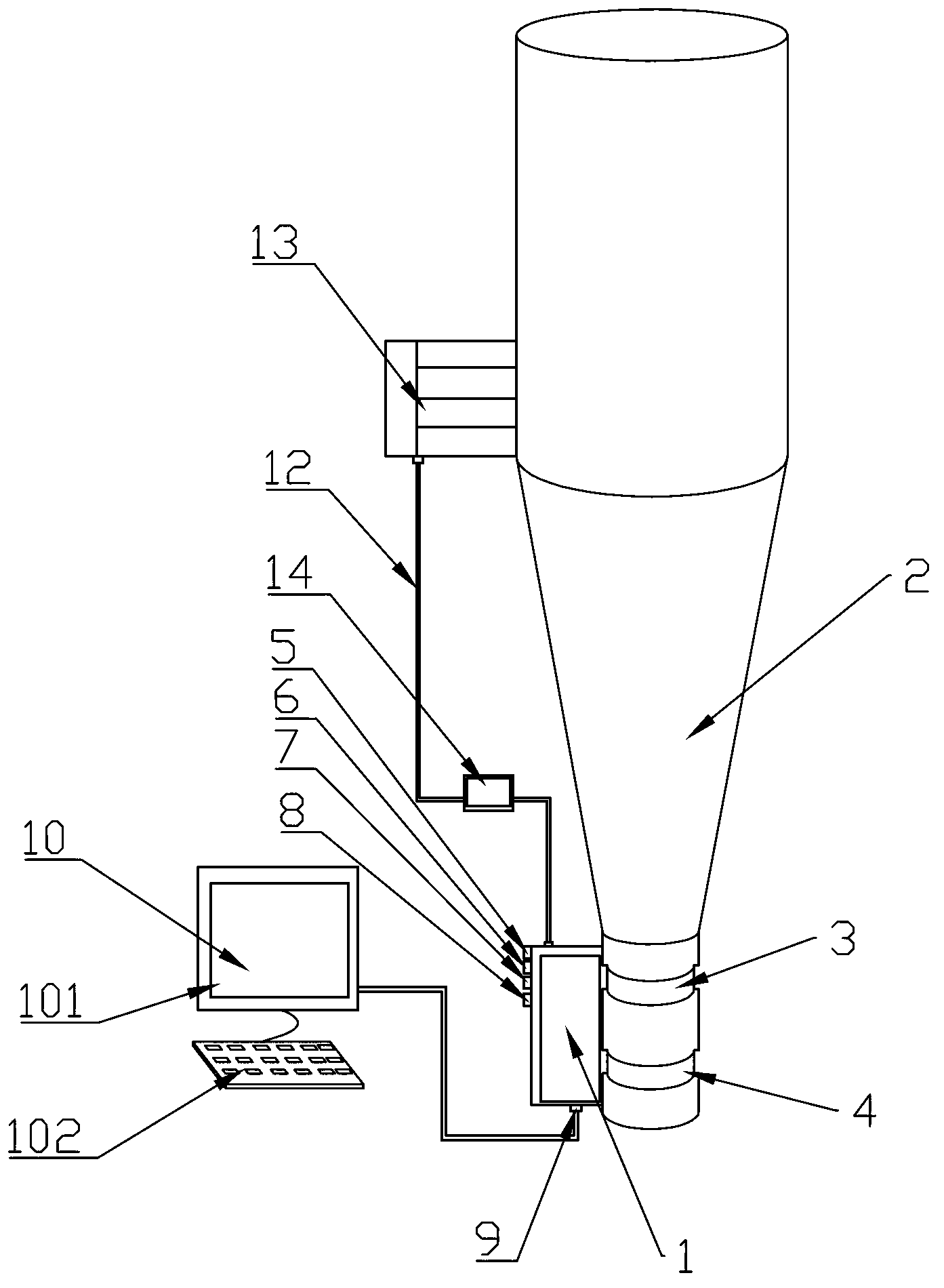

[0013] like figure 1 As shown, an intelligent double-layer ash unloading device of the present invention is characterized in that it includes a controller 1, and the controller 1 is an embedded controller, which adopts an embedded structural design, so that the controller and each execution detection The mechanism is integrated in one body, and can independently and intelligently complete the predetermined functions. The controller 1 is connected to the upper automatic valve 3 and the lower automatic valve 4 provided in the ash hopper 2 of the dust removal equipment, and the upper automatic valve 3 is set on the controller 1 to control the opening of the upper automatic valve 3. The upper automatic valve 4 closes the upper automatic valve closes the position proximity switch 6 and the lower automatic valve 4 opens the lower automatic valve closes the position proximity switch 7 and controls the lower automatic valve 4 closes the lower automatic valve closes the position proxim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com