Quart continuous melting furnace

A continuous melting furnace and quartz technology, applied in the field of quartz production equipment, can solve the problems of uneven heating of continuous melting furnace and insufficient diameter of quartz tube

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

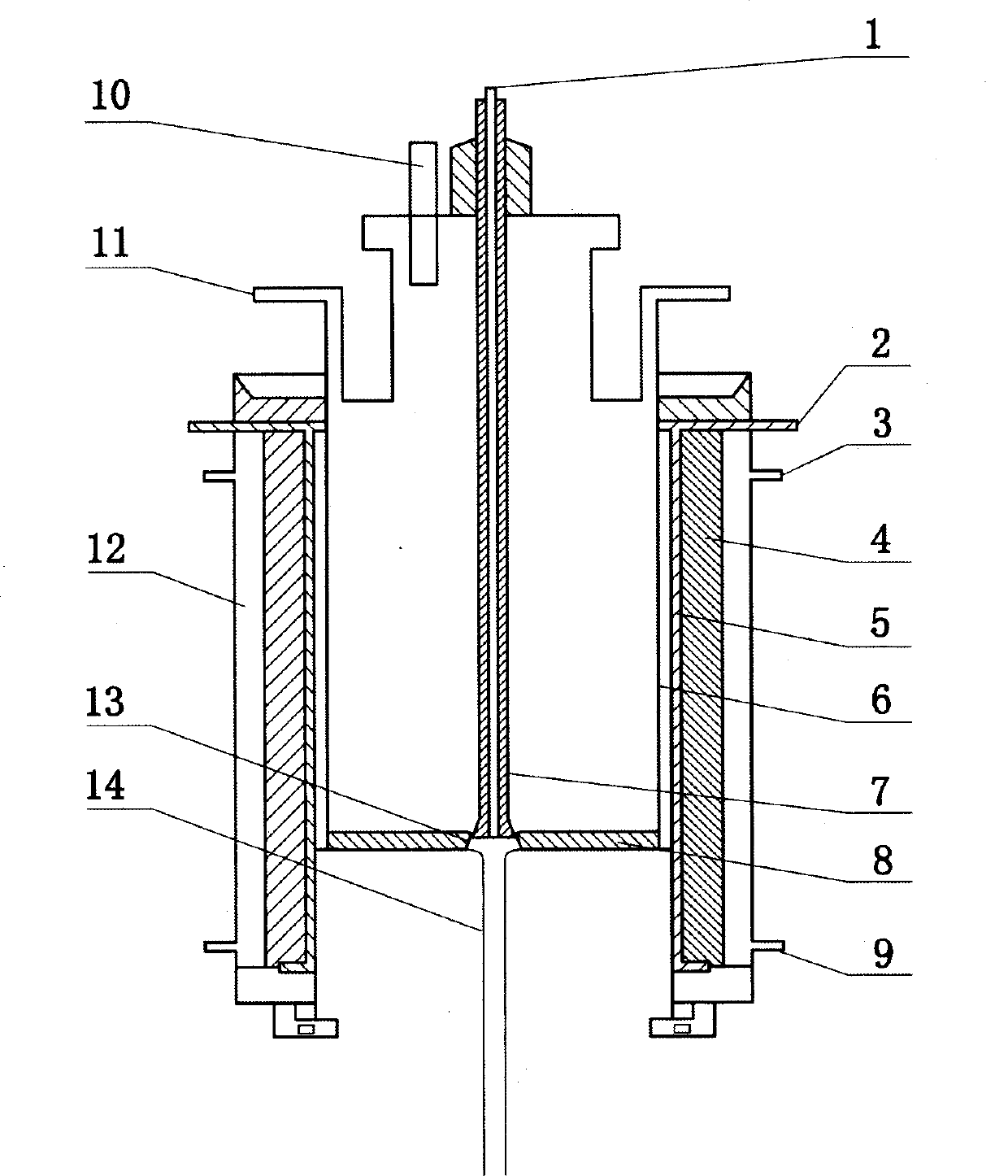

[0014] Such as figure 1 Shown, a kind of quartz continuous melting furnace comprises furnace body 12, is located at the tungsten crucible 6 in the furnace body, is located at the insulating layer 4 between tungsten crucible 6 and furnace body 12 walls, and tungsten crucible 6 tops are provided with feed pipe 10 and The tungsten core rod protective gas inlet 1, the bottom of the tungsten crucible 6 is provided with a forming material table 8, the middle of the material table 8 is provided with a forming port 13, a tungsten core rod 7 is provided at the forming port 13, and a heating device is provided outside the tungsten crucible 6 The device, the heating device is composed of molybdenum electrode 2 and molybdenum mesh 5, and is characterized in that: 6 groups of molybdenum mesh 5 evenly cover the outside of the crucible 6.

[0015] Further, the distance between the molybdenum meshes 5 is 2-2.5mm.

[0016] Further, the diameter of the forming opening 13 is in the range of 3-4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com