Knitting method of fabric by flatbed knitting machine

A technology for knitted fabrics and flat knitting machines, which is applied to weft knitting, flat knitting machines with individual moving needles, and knitting, and can solve problems such as rising device costs, complicated devices, and increased use of knitting threads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

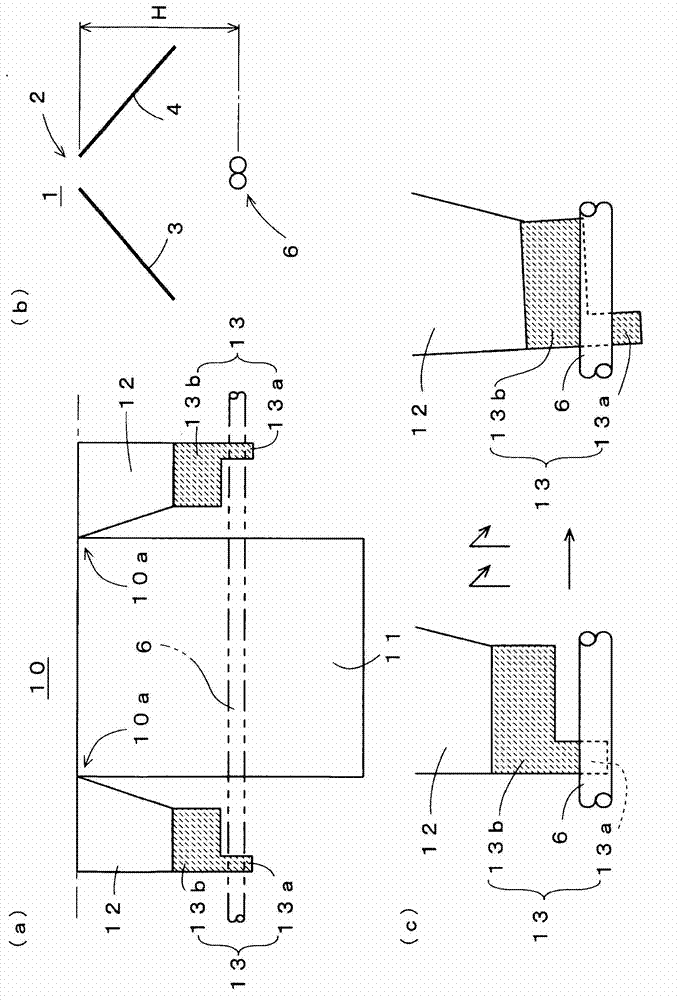

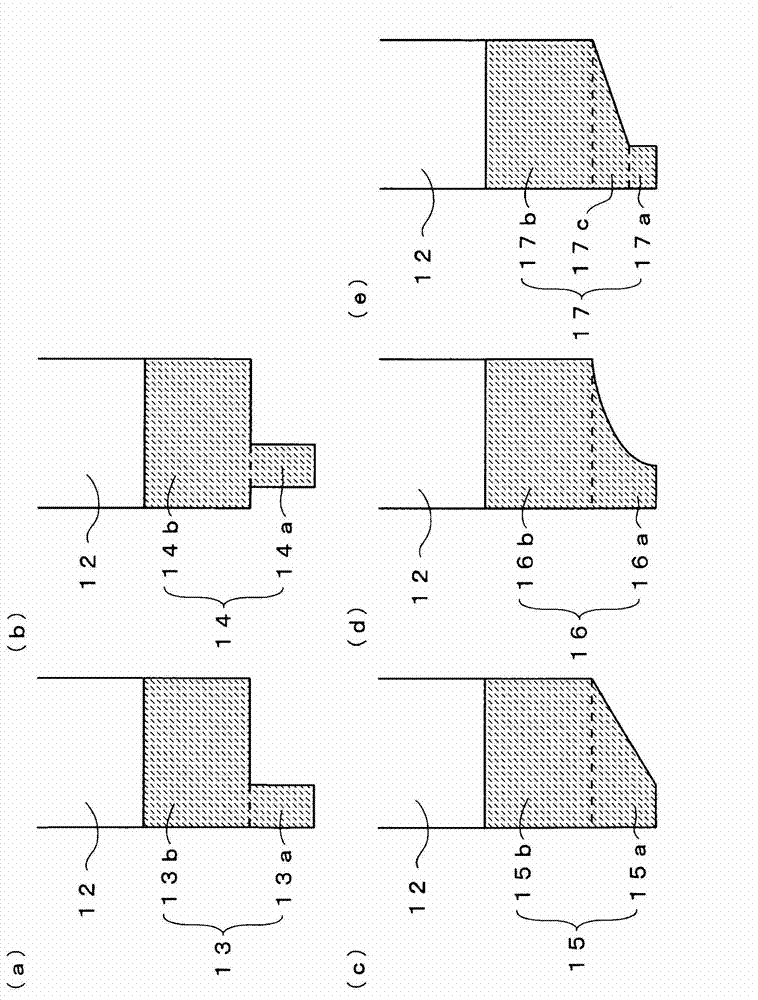

[0035] figure 1In (a), as Embodiment 1 of the present invention, the state in which the joint knitting method of knitted fabric according to the present invention is applied to the knitted fabric 10 is simplified and shown, and in (b), the knit used for knitting is shown in simplified form. The structure of the flatbed knitting machine 1 is shown in simplified form, and (c) shows the effect when joint knitting is performed by the pine-eye course portion 13 . In Embodiment 1 of the present invention, the knitwear 10 is also woven as a tubular knitted fabric in which the sleeves 12 are separated on both sides of the body 11, and joined when reaching the armpit 10a to form a tubular body. Then, in order to reduce the diameter of the cylindrical body, approaching is performed to narrow the knitting width. The weaving and knitting of the knitted fabric 10 itself formed by such weaving Figure 4 The knitwear 5 of (b) is performed in the same manner.

[0036] That is, if figure ...

Embodiment 2

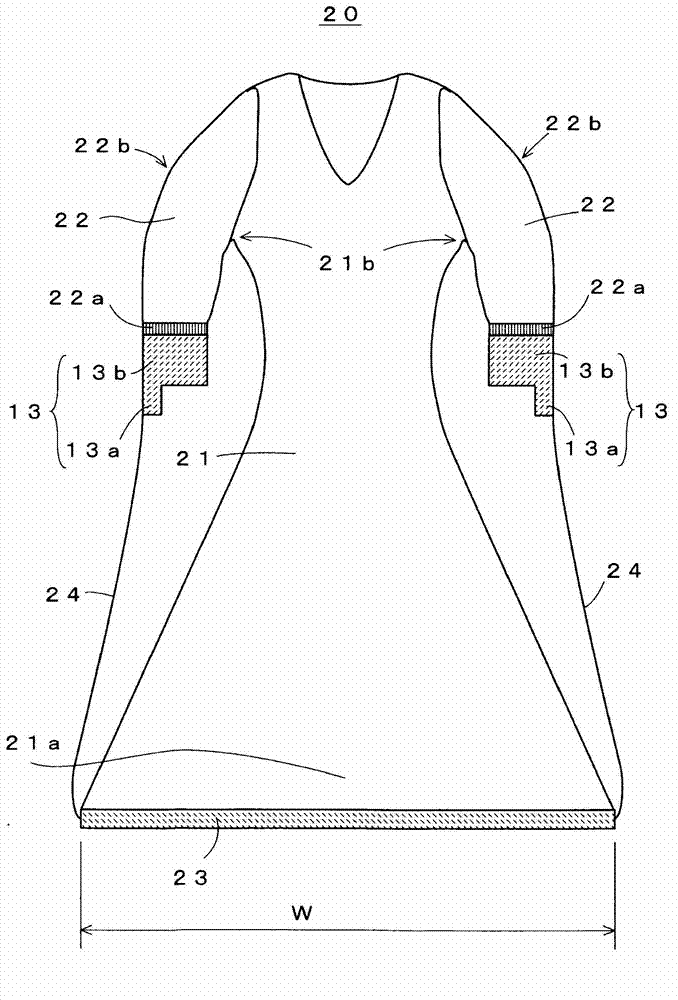

[0045] image 3 The simplified structure of the knitted fabric 20 to which the joint knitting method of the knitted fabric according to Example 2 of the present invention is applied is shown. The body part 21 which becomes the basic knitted fabric of the knit fabric 20 has the shape which continues integrally with the skirt part 21a which hem spreads. At least the lower end side of the skirt portion 21a is knitted using a range W that is a wide range of needle beds 3 and 4, and the range W includes a segment for knitting the sleeve 22 that is shorter than the body 21. The pine eye course portion 13 starts knitting within the range W of the needle bed section used for knitting the skirt portion during knitting of the body 21 . The sleeves 22 to be the additional knitted fabric are knitted from the cuff opening 22a continuous with the pine eye course part 13, and are joined to the body part 21 after knitting in parallel until the body part 21 is knitted to the underarms 21b. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com