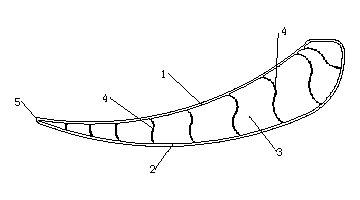

Inner fin of highway guardrail

A kind of guardrail and high-speed technology, applied in the direction of roads, road safety devices, roads, etc., can solve the problems that the guardrail is easily damaged, and the guardrail cannot provide protection, so as to achieve firm and tight connection, good absorption of impact force, and improved safety performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Combine below figure 1 Specific description embodiment:

[0013] An inner wing of a high-speed guardrail is characterized in that the inner wing of the high-speed guardrail includes a wing body 1, and the wing body 1 shrinks gradually from the head to the tail, and the wing body 1 includes a shell 2 and a hollow body. Cavity 3, the cavity 3 is provided with a number of internal ribs 4, the internal ribs 4 are S-shaped, and the R angle 5 of the tail of the wing body 1 is 0.5-0.7 degrees.

[0014] Preferably, the shell is processed by extruding PVC resin through toughening and modifying formula.

[0015] Preferably, the thickness of the outer shell is 2.5-3.0mm, and the thickness of the inner rib is 0.8-1.0mm.

[0016] When the inner wing of the high-speed guardrail provided by the present invention is in use, the entire inner wing is arranged inside the outer wing, so that the inner wing and the outer wing are closely connected. The wing body gradually shrinks from th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap