Filling device for mixing and filling emulsion explosive on scene

An emulsion explosive and on-site technology, which is applied in blasting and other directions, can solve the problems of slow charging speed, many auxiliary processes, and high cost, and achieve the effects of increasing charging speed, saving side power, and reducing equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

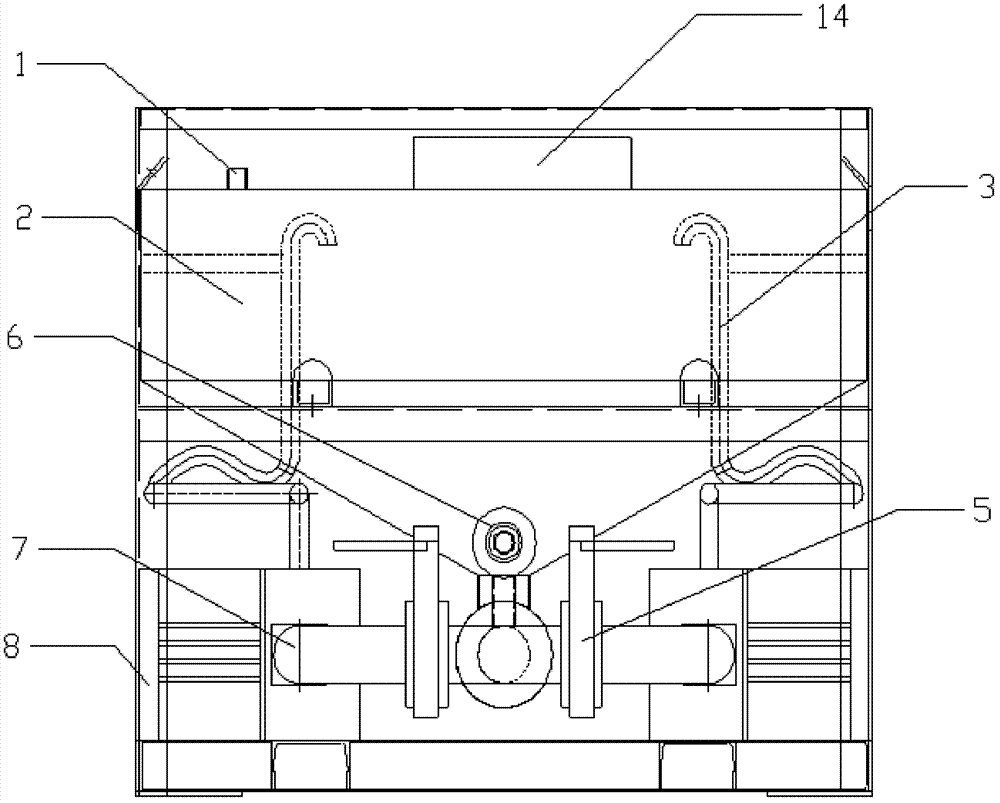

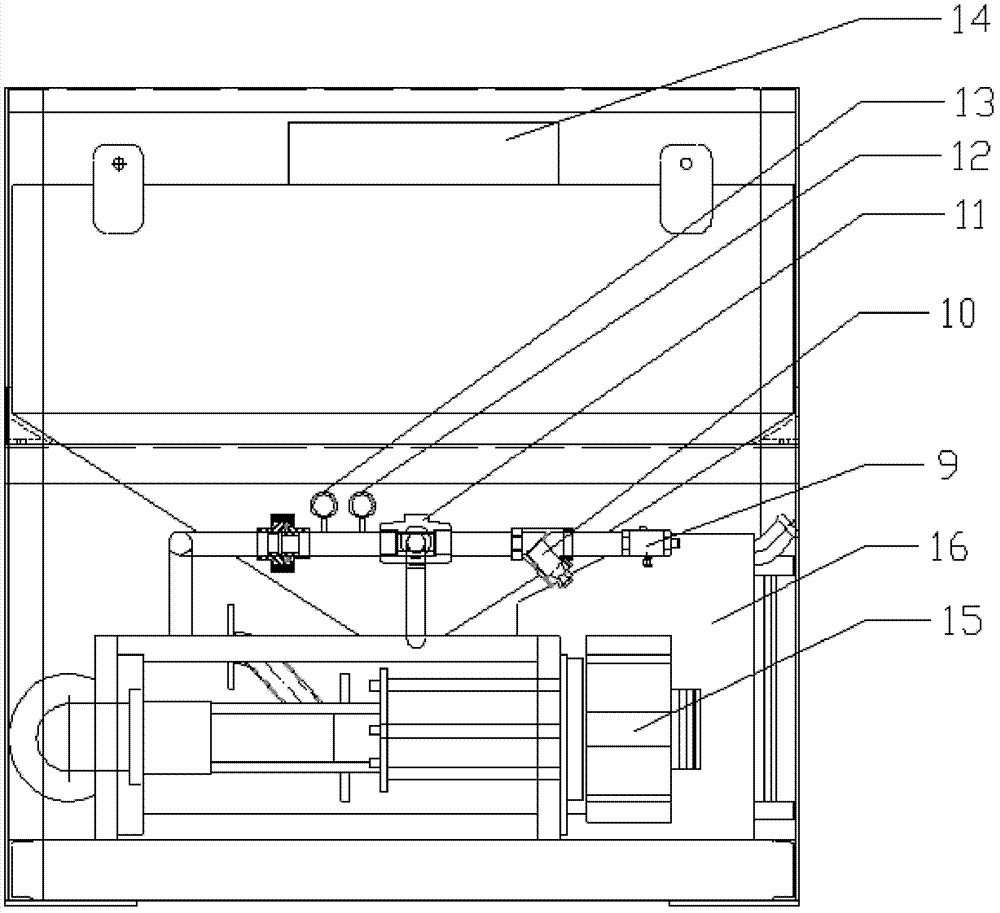

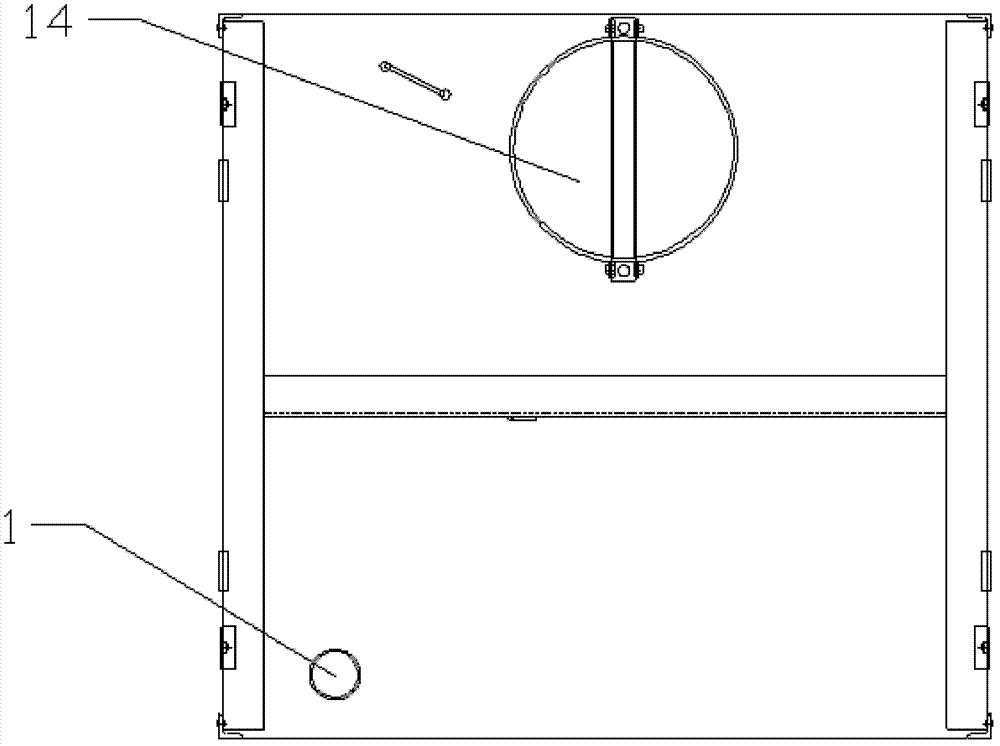

[0028] Embodiments of the present invention provide an on-site mixing and filling device for emulsion explosives of the present invention, comprising a matrix storage container, more than one sensitizing liquid storage container, a cleaning water storage container, a support frame and a filling control system, the matrix storage container Set on the supporting frame; the sensitizing liquid storage container, the cleaning water storage container and the filling control system are all set in the supporting frame; the filling control system includes more than two sets of filling equipment; the filling equipment includes a power system, a matrix pump, sensitizing liquid pump, substrate filter and water ring injector; the power system provides power for the substrate pump and the sensitizing liquid pump; the feed port of the substrate pump is connected with the substrate storage container, and the substrate pump The discharge port is connected with the substrate filter and the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com