The filling system based on the combination of source grain shell and detonator seat

A technology of seismic source charge and detonator seat, which is applied in the direction of ammunition, offensive equipment, weapon accessories, etc., can solve the problems of low degree of automation, affecting factory production efficiency and product quality, and achieve high degree of automation, which is beneficial to product quality control and delivery efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

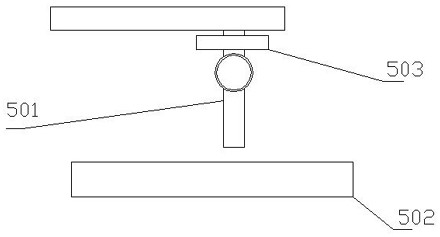

[0022] As shown in the accompanying drawings, the present invention includes a powder column metering charging device 501, a powder column shell delivery device 502 and a detonator seat filling device 503;

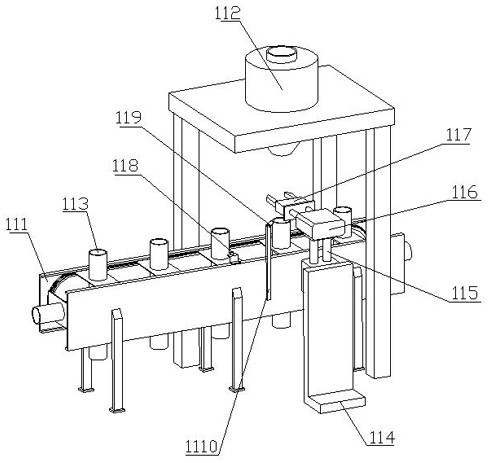

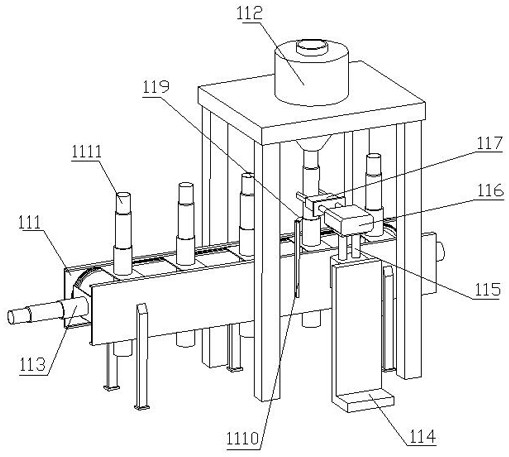

[0023] The drug column metering and charging device 501 includes a chain plate conveyor 111, a drug column clamping assembly and a warehouse-type weighing scale 112. Each chain plate of the chain plate conveyor 111 is provided with a first drug column containing barrel 113, and the chain plate Conveyor 111 is installed on the ground through supporting feet, and the drug column clamping assembly includes cylinder support plate 114, B lifting cylinder 115, C telescopic cylinder 116 and air claw 117, and cylinder support plate 114 is installed on the ground on one side of chain conveyor 111 Above, B lifting cylinder 115 is vertically and detachably installed on the cylinder support plate 114 through bolts, C telescopic cylinder 116 is horizontally and detachably mounted on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com