Rapid construction device suitable for high temperature fire zone

A technology of construction device and fire zone, which is applied in the field of rapid construction device, can solve the problems such as the distance between flying rocks and blasting, the difficulty of ensuring the quality of charge and filling, and the inconvenient loading of charge columns into blastholes, etc., so as to achieve blasting Large volume, shortening the time of water injection and cooling, and improving the effect of blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

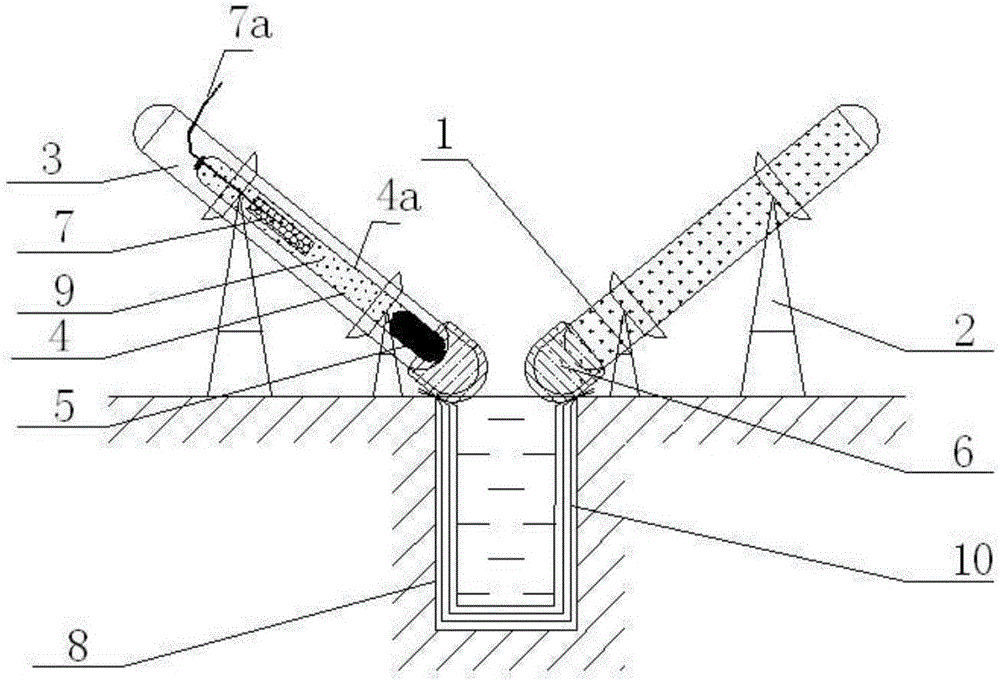

[0022] like figure 1 and 2 Shown: the present invention is applicable to the rapid construction device of high temperature fire zone by front low bracket 1, back high bracket 2, chute 3, charging bag 4, counterweight material 5, end cover 6, detonating charge package 7, blast hole 8. Composed of explosives 9, blast hole water storage bags 10 and other components.

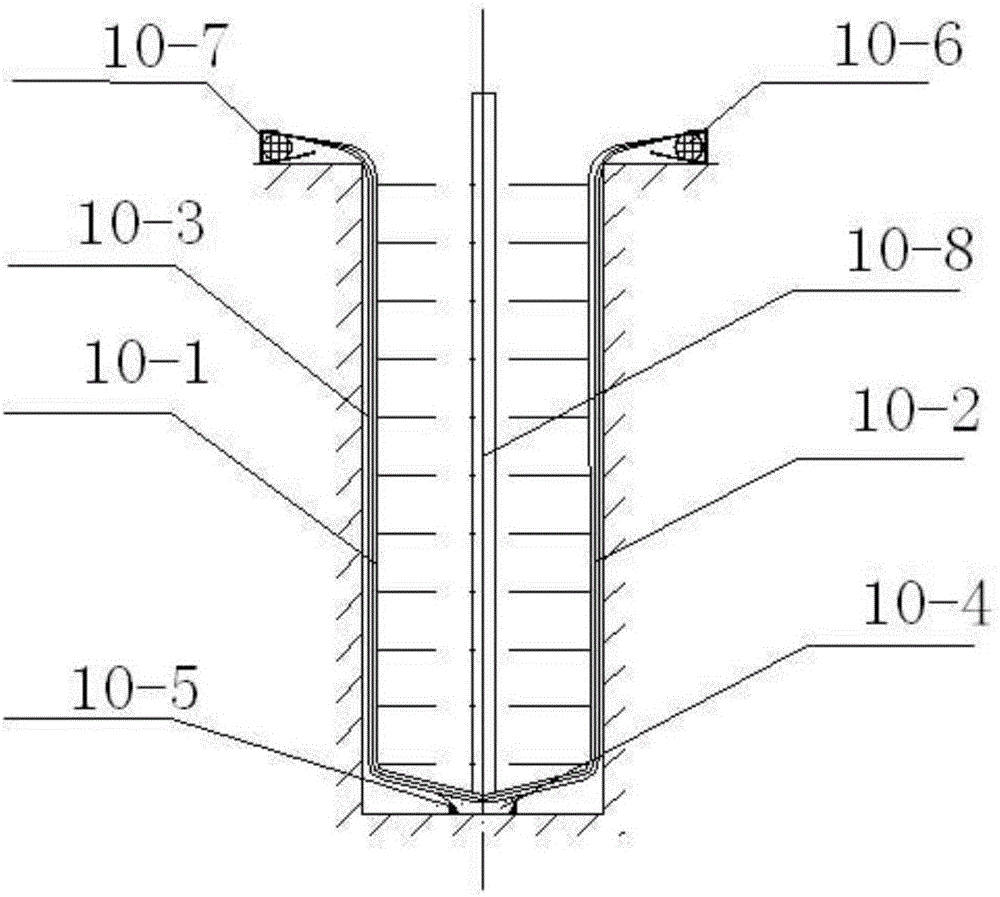

[0023] The blast hole 8 is equipped with a blast hole water storage bag 10, the blast hole water storage bag 10 is composed of a waterproof material layer 10-1, a slip resistant material layer 10-2, a high temperature resistant material layer 10-3, a closed joint 10-4, an iron wire 10-5, The casing iron ring 10-6, the tool clip 10-7, the blasthole support rod 10-8 and other components are composed.

[0024] The blasthole water storage bag 10 is a cylindrical bag body formed by bonding a waterproof material layer 10-1, a slip-resistant material layer 10-2, and a high-temperature resistant material layer 10-3 sequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com