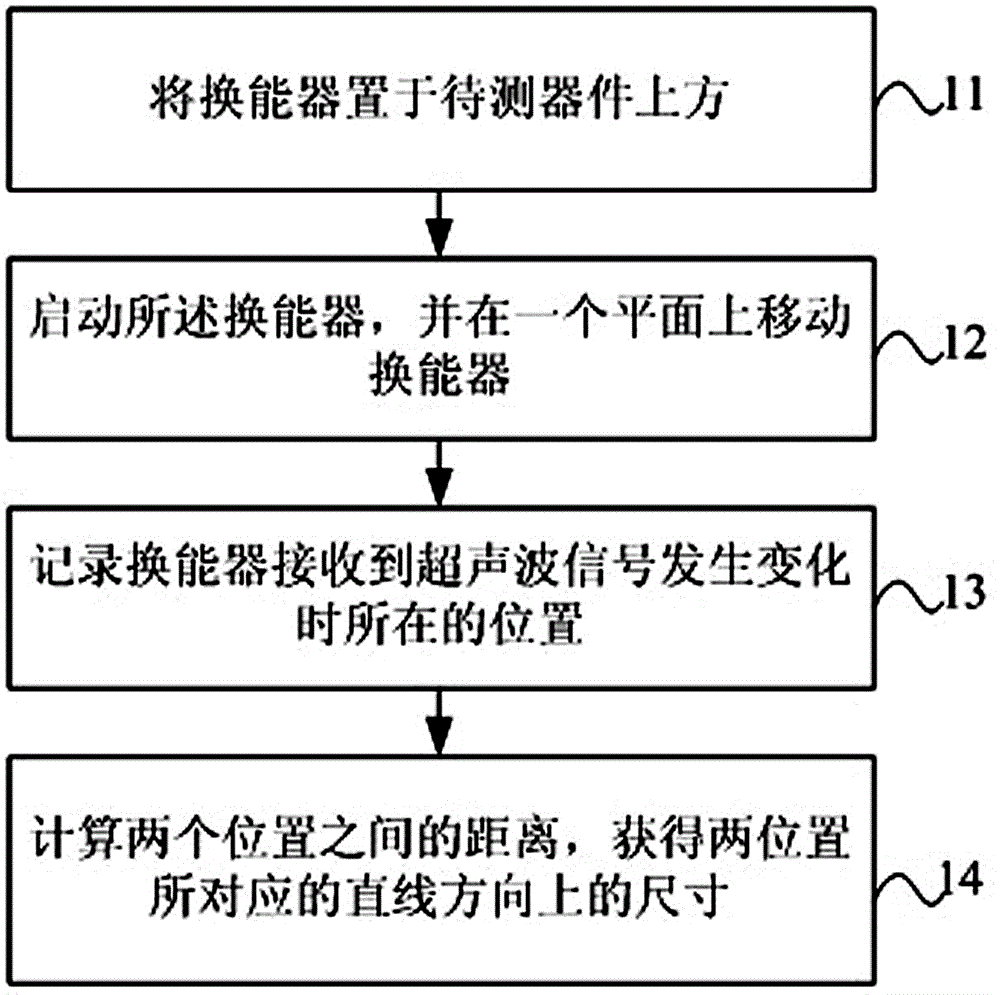

Ultrasonic based edge detection method

An edge detection and ultrasonic technology, applied in the field of measurement, can solve the problems of reducing the efficiency of detection, time-consuming, labor-intensive, errors, etc., and achieve the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] Ultrasonic waves are sound waves with a frequency exceeding 20Khz. Because of its very short wavelength, it propagates in a straight line like light waves. Some of the ultrasonic waves are reflected at the interface, and some will pass through the interface. The relative strength of ultrasonic reflection and transmission at the interface is determined by the acoustic impedance of the materials on both sides of the interface. Ultrasonic has the advantages of high resolution and high sensitivity. Using ultrasonic flaw detection can detect the size, position and shape of subtle defects in real time. Ultrasound is often used in non-destructive testing equipment (such as: ultrasonic scanning microscope), using sonar to find submarines and fish schools, physical examination equipment, ultrasonic cleaning machines (15~50KHz), ultrasonic humidifiers, ultrason...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com