Device and method for testing dynamic characteristics of single-screw or double-screw rolling supporting linear feed system

A technology of linear feed system and rolling support, which is applied in the direction of machine gear/transmission mechanism testing, etc., which can solve the problem that there is no double-screw span adjustment, the measurement of double-screw feed system cannot be realized, and the dynamic measurement of lead-screw span cannot be realized. characteristics, etc., to achieve the effect of clear test principle, compact structure, and easy and accurate acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

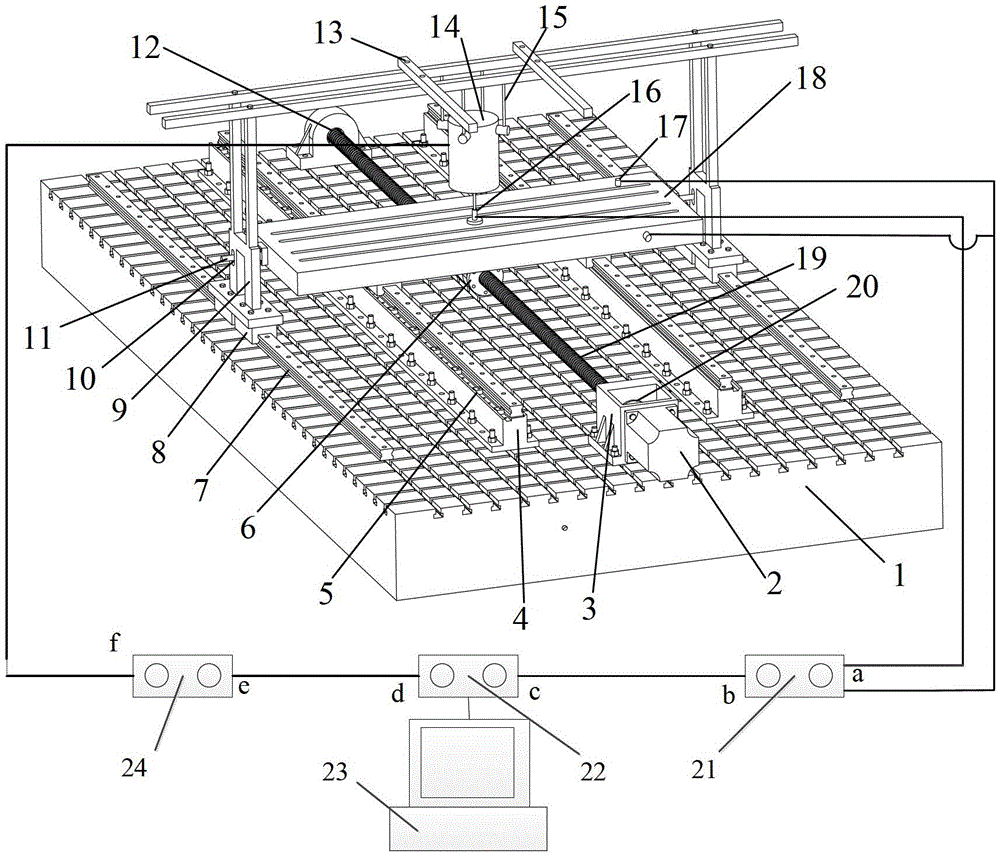

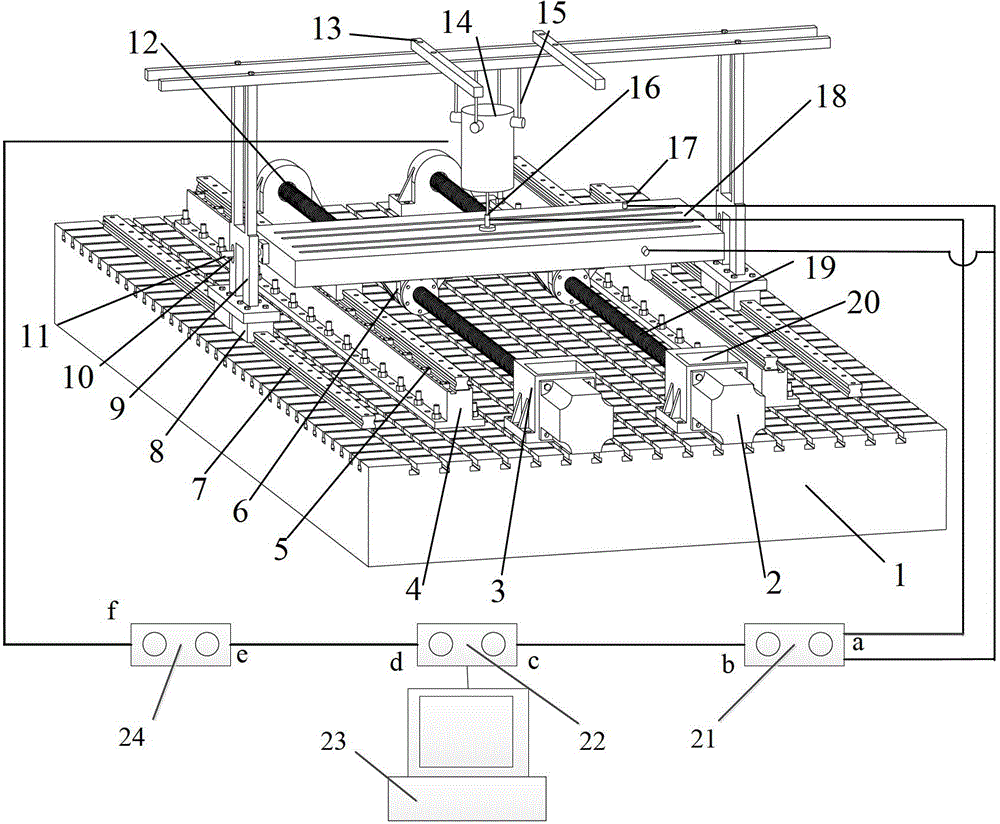

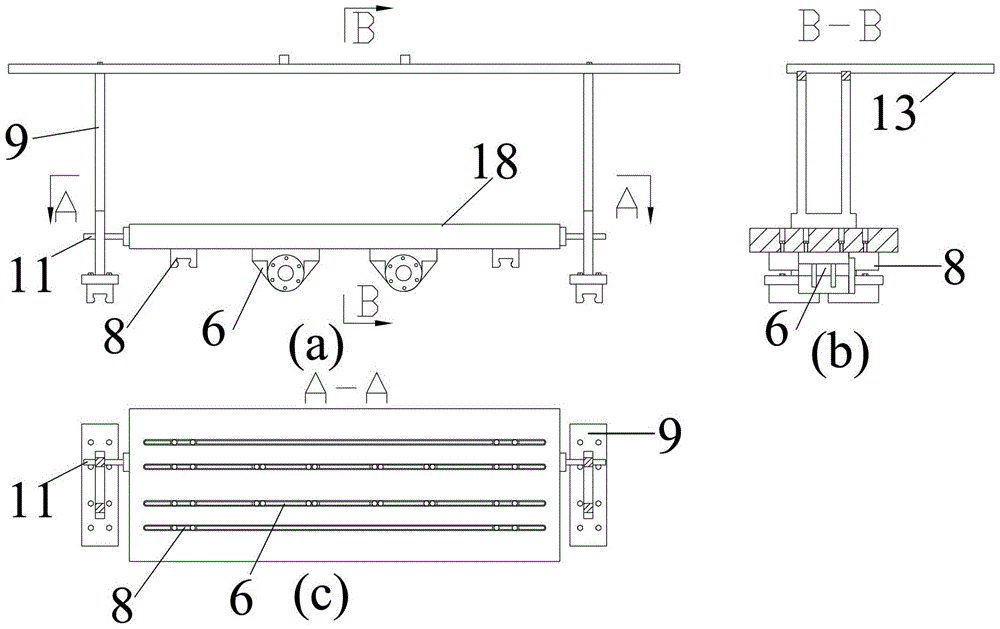

[0028] A device for testing the dynamic characteristics of a linear feed system with single and double lead screw rolling support, including a base 1, a guide rail mounting plate 4, a rolling guide rail 7, a rolling guide rail slider 8, a wedge block 5, a bearing seat 3, a bearing 12, and a shaft coupling 20. Ball screw pair 19, nut seat 6, motor 2, workbench 18, synchronization frame 9, synchronization push rod 11, rubber ring 10, suspension rod 13, vibrator 14, elastic rope 15, piezoelectric acceleration sensor 17. Impedance head 16, data collector 22, charge amplifier 21, power amplifier 24 and PC 23;

[0029] The upper surface of the base 1 is provided with mutually parallel and equidistant T-shaped grooves in both the transverse direction and the longitudinal direction, and two mutually parallel rolling guide rails 7 are fixedly connected to the outermost two longitudinal T-shaped grooves on the upper surface of the base 1 . The direction of extension is longitudinal, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com