Thermal cycle test equipment and test method

A test equipment and thermal cycle technology, used in measuring devices, instruments, scientific instruments, etc., can solve the problems of unbalanced thermal strain shock, small temperature difference, and inability to meet the requirements of the radiator, and achieve the effect of meeting the requirements of thermal cycle testing.

Inactive Publication Date: 2013-09-25

SOUTH AIR INT

View PDF8 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

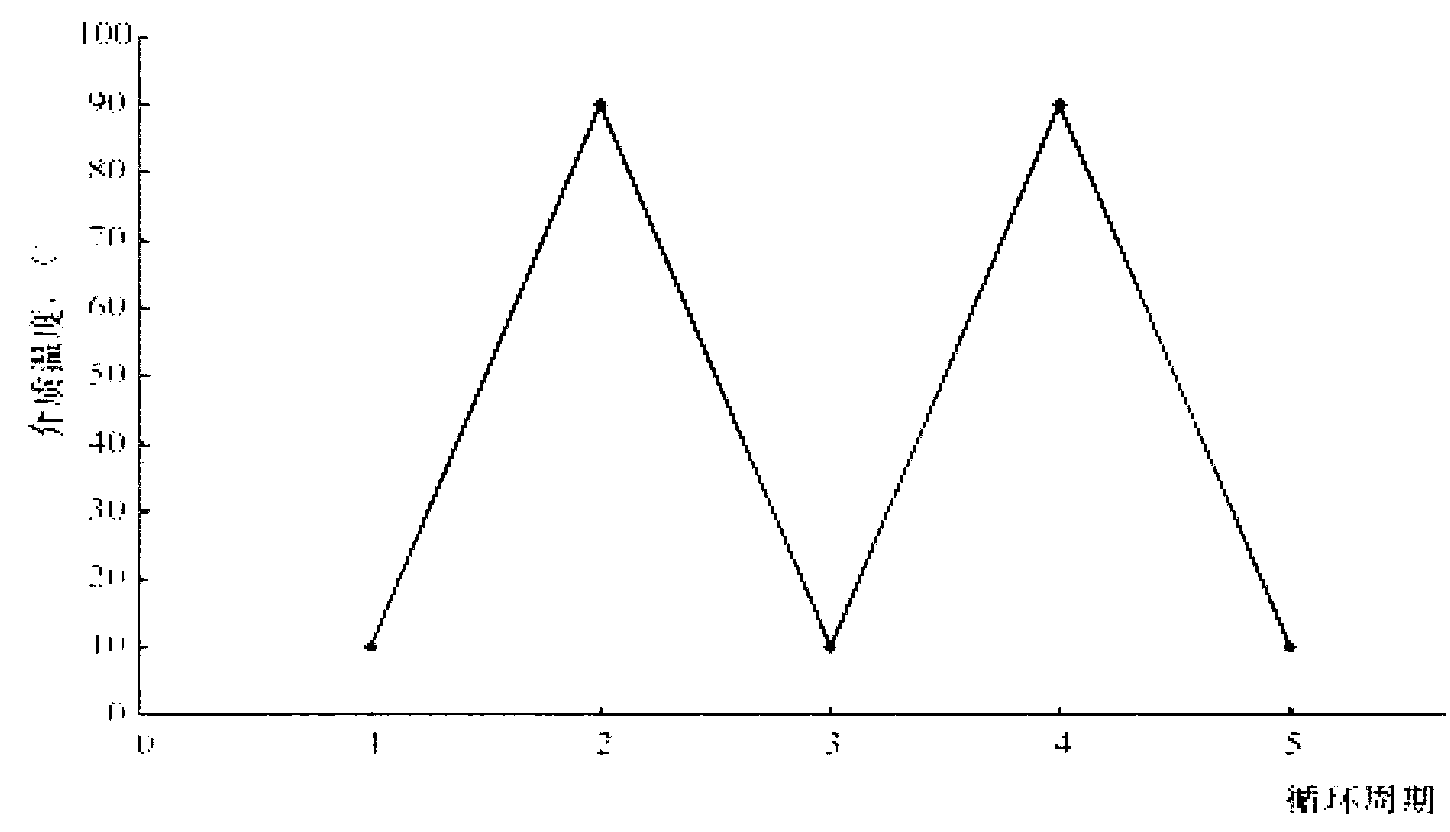

[0004] 1. Since both the high-temperature medium and the low-temperature medium use the same pump 4 to provide circulation power, and the heat exchange between the medium and the pump 4 occurs when the medium passes through the pump, the temperature of the medium injected into the test piece 3 rises and falls relatively gently. The temperature difference is small, and it is impossible to do a severe thermal strain impact test on the product, such as figure 2 shown;

[0005] 2. The thermal cycle test equipment cannot complete thermal cycle and thermal shock tests at temperatures below 0°C and lower;

[0006] Since the vehicle radiator contains components with large differences in thickness, heat storage, and thermal strain, such as fastening water chambers, sealing rings, fins, flat

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

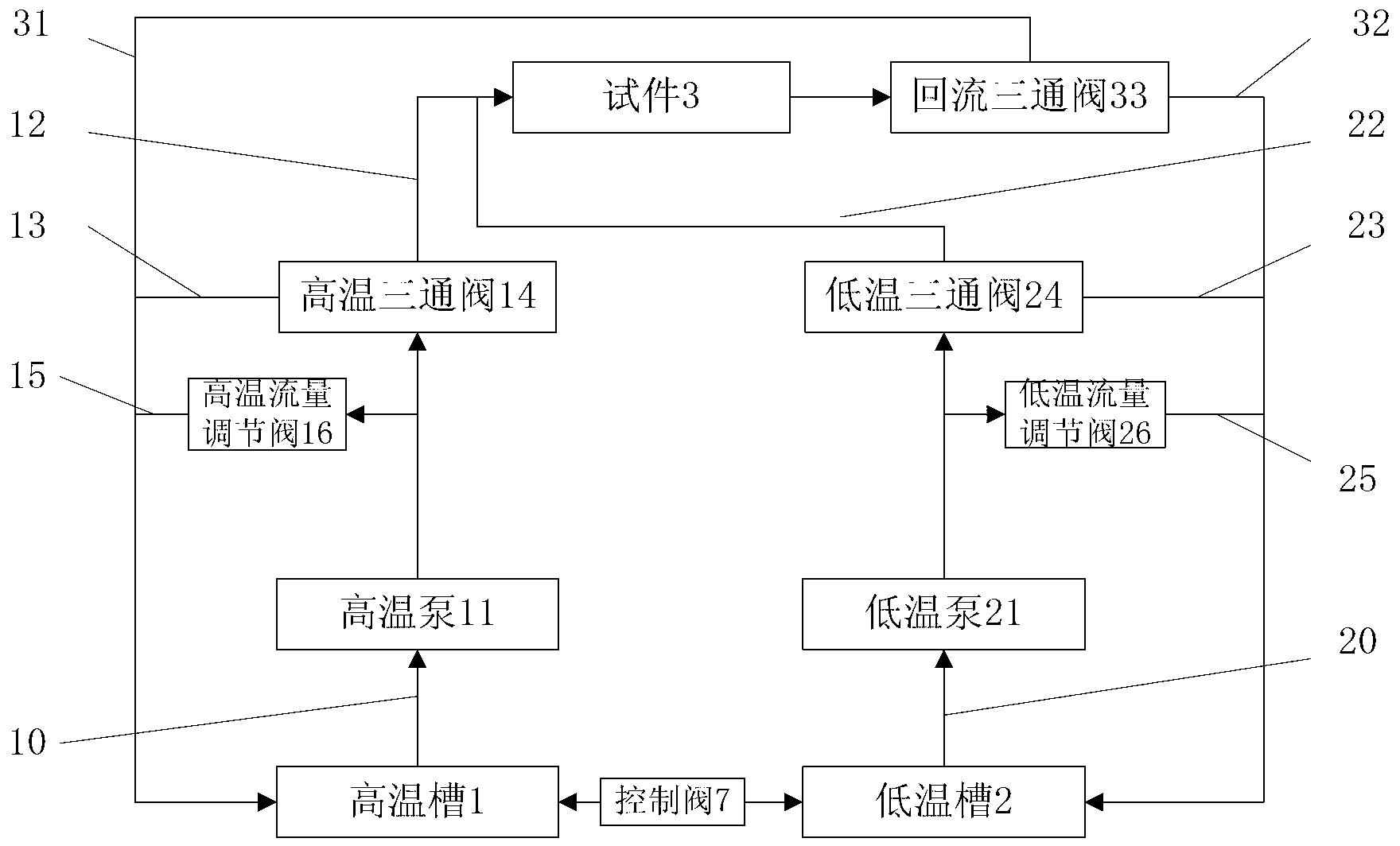

The invention discloses thermal cycle test equipment. The thermal cycle test equipment comprises a high-temperature tank, a low-temperature tank and a circulating pipeline system, wherein the circulating pipeline system comprises a high-temperature medium pipeline connected with the high-temperature tank, a low-temperature medium pipeline connected with the low-temperature tank, and a reflux pipeline used for medium reflux, the high-temperature medium pipeline is provided with a high-temperature pump, a high-temperature connecting pipe is arranged between an outlet of the high-temperature pump and a medium inlet of a test specimen, a high-temperature heat exchange pipe is arranged between the outlet of the high-temperature pump and the high-temperature tank, the low-temperature medium pipeline is provided with a low-temperature pump, a low-temperature connecting pipe is arranged between an outlet of the low-temperature pump and the medium inlet of the test specimen, a low-temperature heat exchange pipe is arranged between the outlet of the high-temperature pump and the low-temperature tank, the reflux pipeline comprises a high-temperature reflux pipeline and a low-temperature reflux pipeline which are arranged in parallel and connected with a medium outlet of the test specimen, the high-temperature reflux pipeline is connected with the high-temperature tank, and the low-temperature reflux pipeline is connected with the low-temperature tank. The invention also discloses a thermal cycle test method. The thermal cycle test equipment and the test method can be used for realizing the rapid change of temperature.

Description

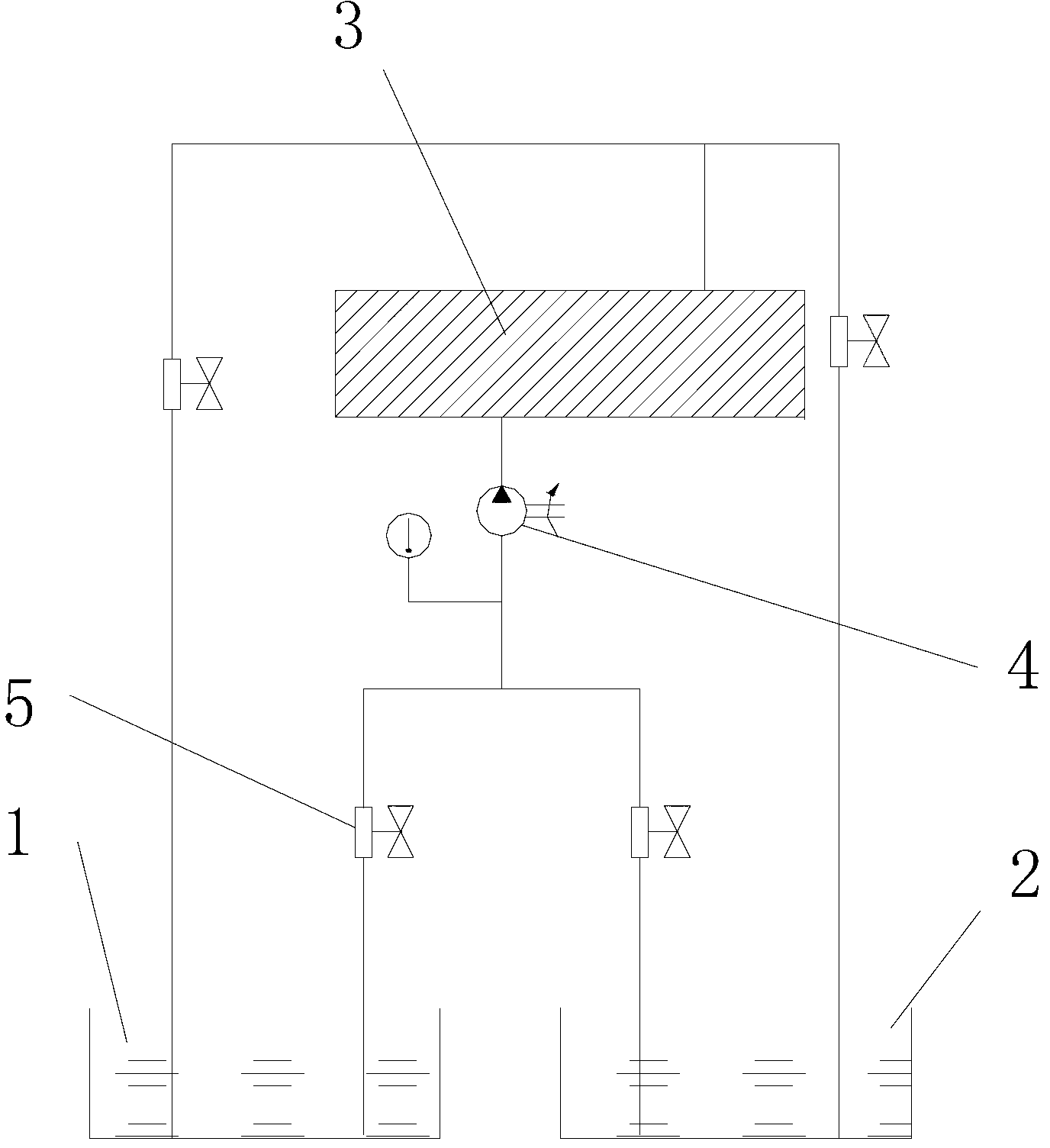

technical field [0001] The invention belongs to the technical field of thermal shock / thermal cycle test, and in particular relates to thermal cycle test equipment and a test method for internal thermal cycle test of a vehicle radiator. Background technique [0002] Such as figure 1 Shown is a structural schematic diagram of an existing heat cycle test equipment. The thermal cycle test equipment includes a high-temperature tank 1, a low-temperature tank 2, and a circulation pipeline arranged between the high-temperature tank 1, the low-temperature tank 2 and the test piece 3. The high-temperature tank 1 and the low-temperature tank 2 are respectively filled with high and low temperature media. In addition, the high-temperature medium and the low-temperature medium are both injected into the test piece 3 through a pump 4. The high-temperature medium pipe and the low-temperature medium pipe are respectively provided with regulating valves 5 for adjusting the flow rate. After p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/60

Inventor 胡昊熊静

Owner SOUTH AIR INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com