Optical fiber composite overhead phase line and system for distributed temperature and strain monitoring

An optical fiber composite, temperature strain technology, applied in the direction of measuring devices, instruments, power cables, etc., can solve the problem of inability to use overhead phase line distributed strain monitoring, and achieve the effect of improving monitoring level and ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

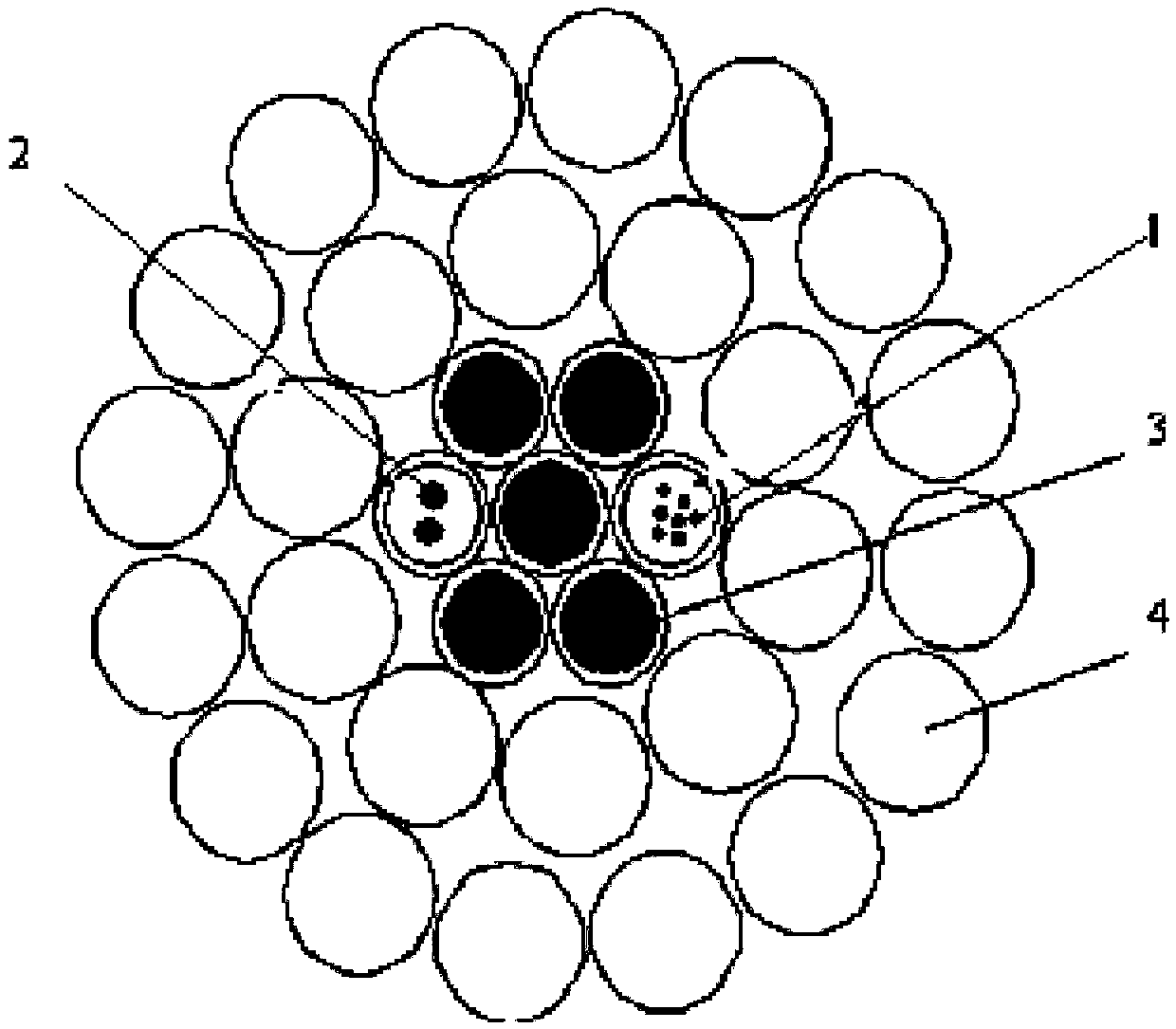

[0011] Such as figure 1 The embodiment shown is an optical fiber composite overhead phase wire for distributed temperature and strain monitoring, which includes an aluminum-clad steel wire 3 twisted together in sequence at the center of the composite overhead phase wire, a bare fiber set in a pipe fitting 1. The single-mode tight-wrapped optical fiber 2 arranged in the pipe and the aluminum wire 4 twisted on the outside of the aluminum-clad steel wire 3, the bare fiber 1 and the single-mode tight-wrapped optical fiber 2, the bare fiber 1 There is an excess length, the number of the single-mode tight-wrapped optical fiber 2 is not less than two, and the two ends of the single-mode tight-wrapped optical fiber 2 are flush with the two ends of the tube where it is located. In this embodiment, the bare fiber 1 is contained. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com