3D printing methods for engineering structures

A technology of engineering structure and 3D printing, applied in manufacturing tools, ceramic molding machines, etc., can solve the problems of layered printing difficulty, high threshold, cost increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

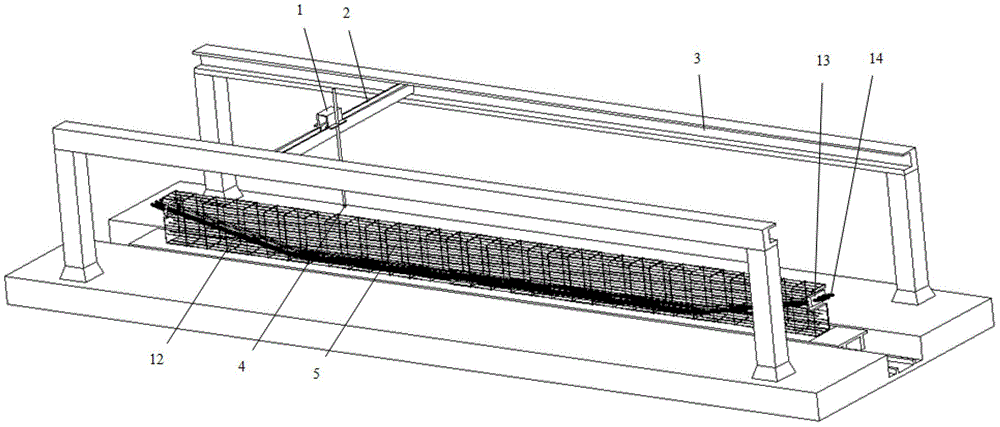

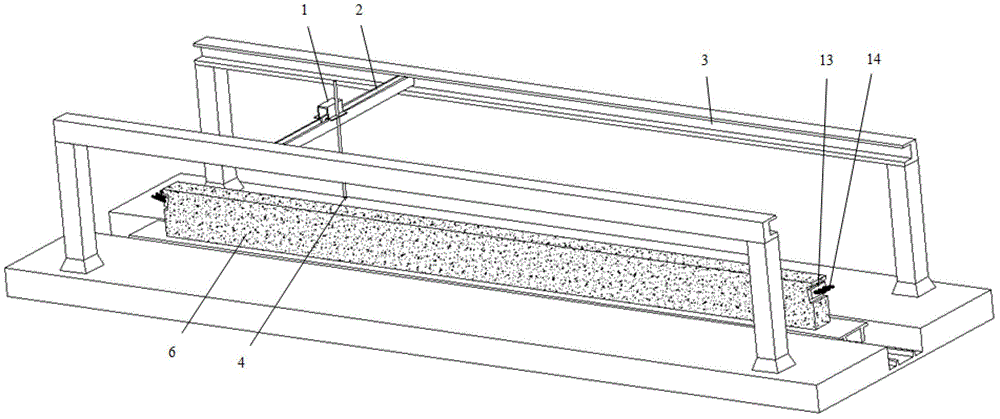

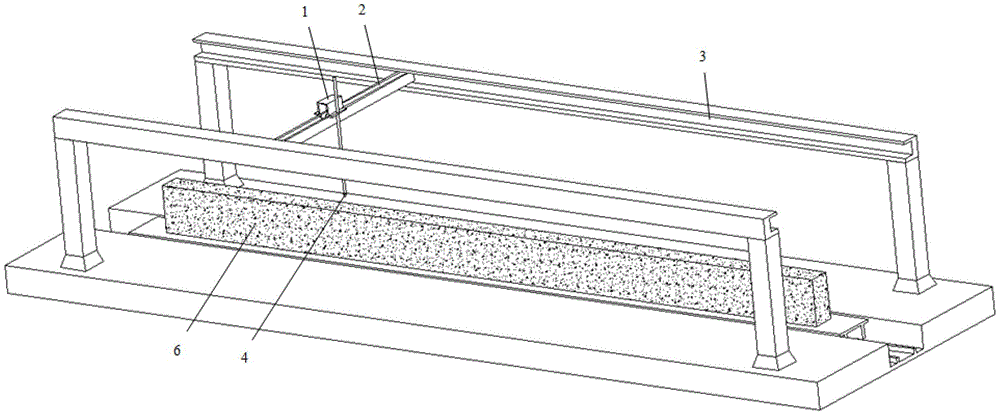

[0035] Example 1 A 3D printing method for a prestressed concrete prefabricated structure

[0036] Example description: A prestressed concrete beam with a span of 32m is manufactured by 3D printing method, such as Figure 1~Figure 4 shown. According to the design, pre-process and manufacture the reinforcement skeleton, position and install prestressed tendon channels, prestress anchors and other accessories on the skeleton, and finally form a complete reinforcement skeleton. Move the reinforced skeleton to the 3D printing platform, and control the printing head that can move and rotate in three directions according to the 3D model of the prestressed concrete beam built in the computer, that is, the spray head that can control the movement and rotation in three directions, and carry out layer by layer. Print. During the printing process, the printing time of each layer was controlled according to the initial setting and final setting ages of the concrete to form a reinforced c...

Embodiment 2

[0041] Embodiment 2 A 3D printing method of a steel-concrete composite structure

[0042] Example: A steel-concrete composite beam with a span of 32m, the steel beam is an I-beam, and it is manufactured by 3D printing method, such as Figure 5~Figure 7 shown. Manufacture the steel beam skeleton in advance according to the design, and then move the steel beam skeleton to the 3D printing platform. According to the 3D model of the steel-concrete composite structure pre-established in the computer, control the printing head that can move and rotate in three directions, that is, Control the three-way moving and rotating jet head to print in layers. During the printing process, the printing time of each layer was controlled according to the initial setting and final setting age of the concrete, and finally a steel-concrete composite beam with a span of 32m was formed. The specific implementation steps are as follows:

[0043] Step 1 Establish a 3D model of the steel-concrete compos...

Embodiment 3

[0046] Embodiment 3 A 3D printing method for prestressed steel cylinder concrete pipe

[0047] Example description: A prestressed steel cylinder concrete pipe with an inner diameter of 3m is manufactured by 3D printing method, such as Figure 8~Figure 11 shown. Manufacture the steel cylinder skeleton in advance according to the design, then move the steel cylinder skeleton to the 3D printing platform, and control the printing head that can move and rotate in three directions according to the three-dimensional model of the prestressed steel cylinder concrete pipe built in the computer, namely The spray head that can control the three-way movement and rotation, sprays concrete inside and outside the steel cylinder, and prints in layers. During the printing process, the printing time of each layer is controlled according to the initial setting and final setting age of the concrete. After the concrete layer is formed, wrap the circumferential prestressed tendons on the outer sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com