Underground unattended operation pass-type tippler system

A technology of a dumper and a mine car, applied in the mining industry, can solve the problems of high labor intensity of workers, low degree of automation, and many transfer links, etc., so as to reduce the labor intensity of workers, improve the efficiency of dumping, and ensure the effect of safe production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

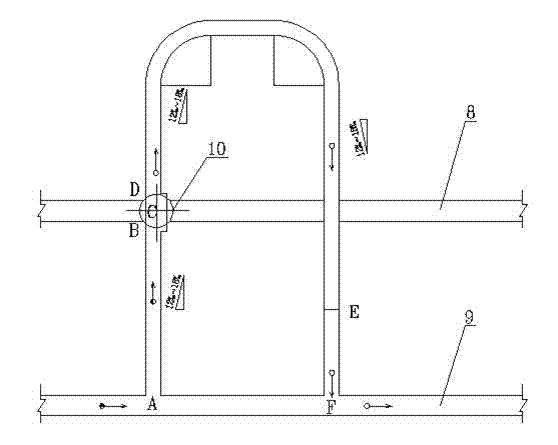

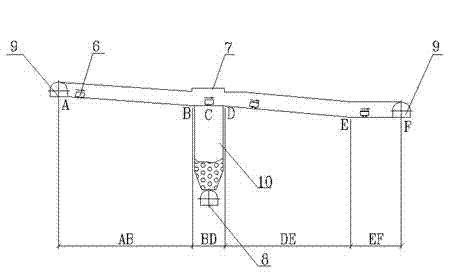

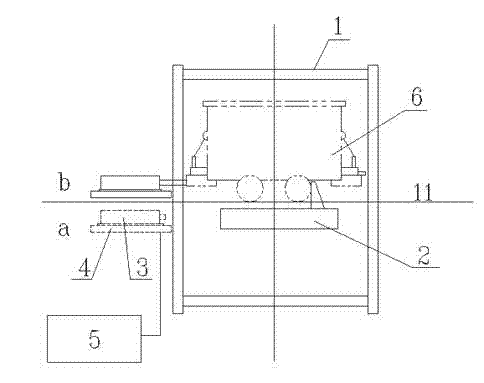

[0016] The accompanying drawing is a specific embodiment of the present invention. attached figure 1 and 2 It is an underground unattended through-type dumper system, which is characterized in that it includes a U-shaped ramp, a dumper 1, an ore transport lane 8, a rail transport lane 9 and a catapult installed on the incoming side of the dumper 1, The rollover system utilizes ramps for shunting. The slope of the U-shaped ramp is 12‰ to 18‰. The ore transport lane 8 is overlapped, and the heavy-duty mine cart 6 filled with ore slides from the rail transport lane 9 to the dumper chamber 7 automatically depending on the slope, and the heavy-duty mine cart 6 is pushed into the dumper 1 by the cart machine. The ore is turned into the ore silo, and the ore enters the ore transport lane 8;

[0017] As shown in appendix 1 and 2, the underground unattended through-type dumper system of the present invention automatically slides the fixed mine car 6 filled with ore from the rail tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com