Method for testing transformer equipment without disassembling lead

A technology that does not remove lead wires and test methods. It is applied to instruments, measuring electrical variables, and measuring current/voltage. It can solve problems such as difficulty and strength, and low safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

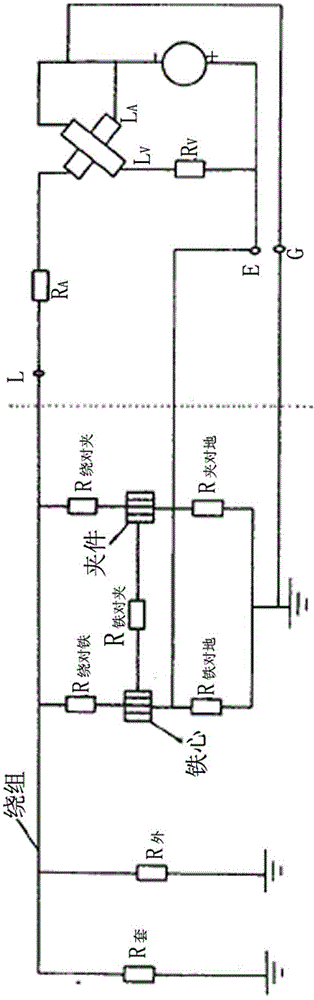

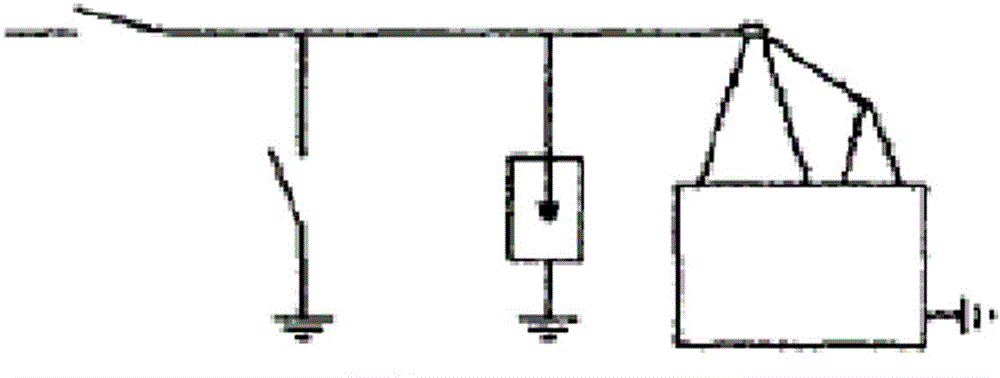

[0032] The invention provides a test method for transformer equipment without removing lead wires. The method includes the measurement of oil-immersed transformers and oil-immersed shunt reactors. The steps of the method are as follows:

[0033] (1) Test the oil-immersed transformer:

[0034] During the transformer test, the neutral point and low-voltage side bushing lead-out wires should be disassembled and fixed with insulating tape. In addition, the iron core of the transformer and the grounding wire of the clip should be disassembled;

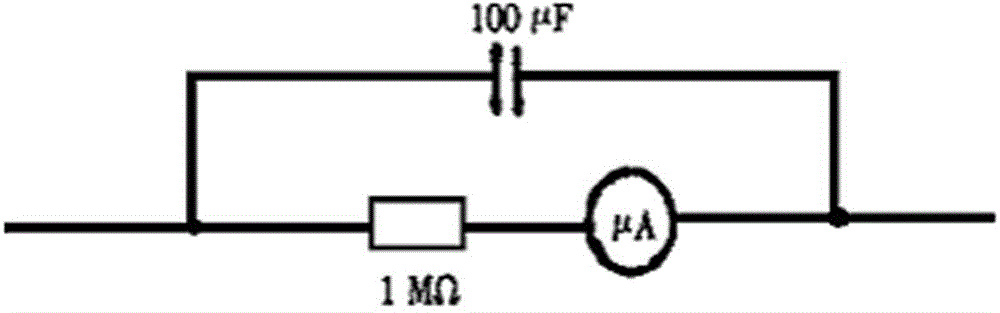

[0035] ①. Use the shielding method to measure the insulation resistance, absorption ratio and polarization index of oil-immersed transformer windings: when testing high-voltage windings, medium-voltage windings and iron cores, low-voltage windings are grounded and the shell is shielded; when testing low-voltage windings and iron cores, high-voltage The winding and medium voltage winding are grounded, and the shell is shielded; when testin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com