A wafer testing method

A wafer testing and wafer technology, applied in the field of wafer testing, can solve the problems of chip defects, testing, bad test results, etc., and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The wafers to be tested are multiple wafers of the same product in the same batch, for example, a box of wafers (25 pieces) in standard production, and the multiple wafers are divided into two groups, and these two groups The testing directions of the wafers are perpendicular to each other. If there is an influence of the test itself, there will be obvious differences on the wafers tested in different directions, so as to directly distinguish whether there is a problem in the test itself.

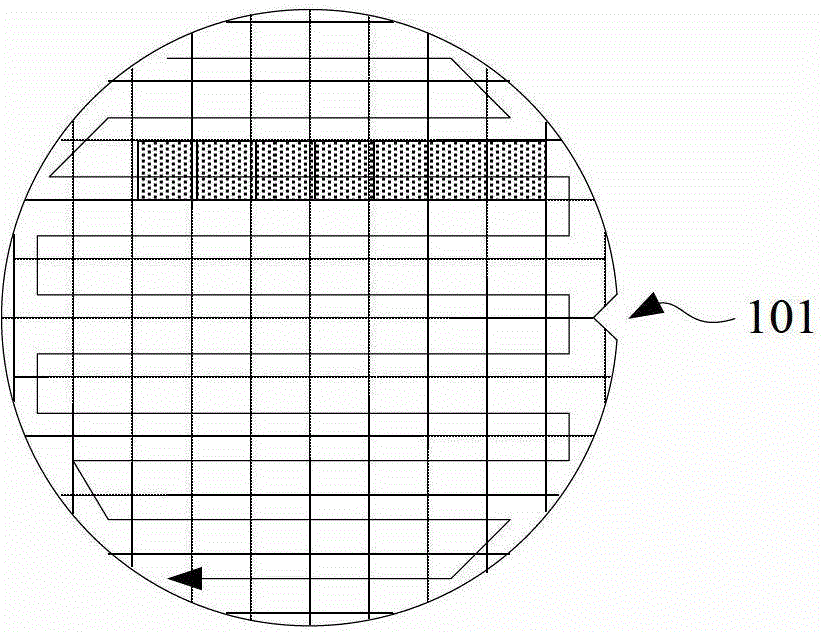

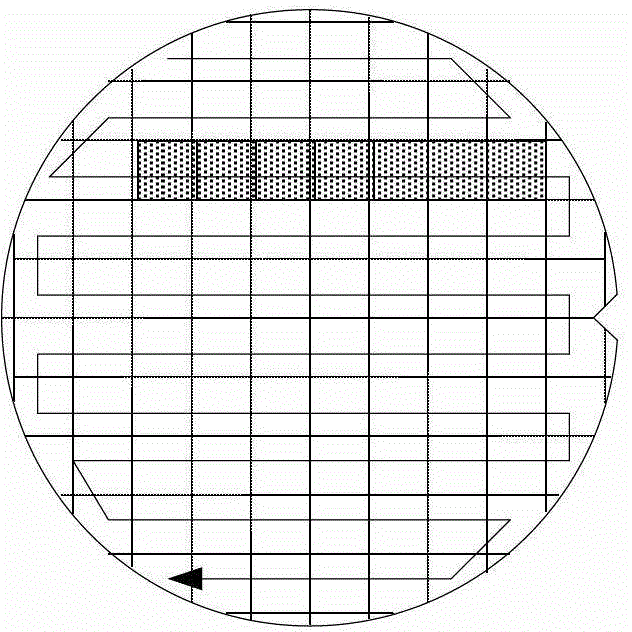

[0024] Preferably, the odd-numbered wafers and the even-numbered wafers are divided into two groups, and the odd-numbered wafers are tested in the first direction; the even-numbered wafers in the plurality of wafers are tested in the first direction perpendicular to the first direction. Test in two directions. better, see Figure 2A to Figure 2B , define the direction of the diameter of the wafer notch and the center of the wafer (the horizontal direction in the figure) as the firs...

Embodiment 2

[0028] In this embodiment, the wafer to be tested is a single wafer, and different regions on the wafer are tested in two mutually perpendicular directions on the wafer to be tested respectively, and the test results can be identified through the test results. Whether the resulting yield distribution is affected by the test issue.

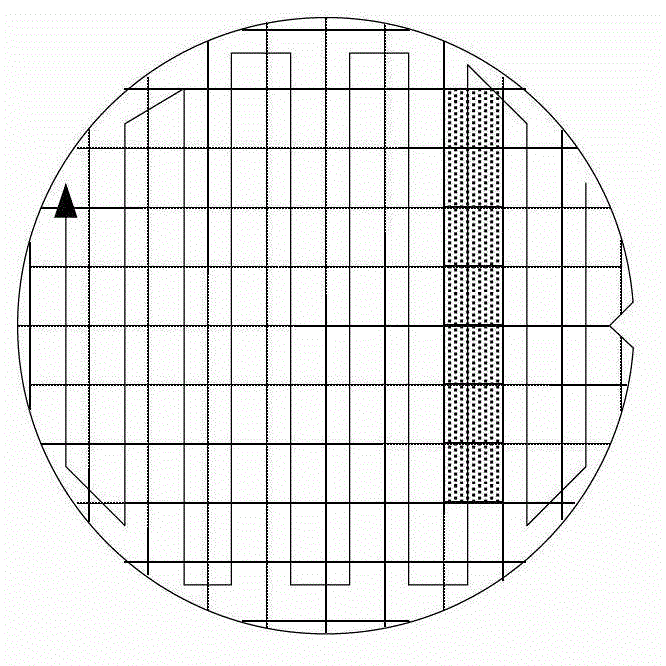

[0029] Specifically, in this embodiment, the wafer is divided into four regions by two mutually perpendicular chords on the wafer, and the directions in which two adjacent regions are tested are perpendicular to each other. Preferably, the wafer is equally divided into four regions by using two mutually perpendicular diameters on the wafer. In this embodiment, one of the diameters is selected as the diameter passing through the wafer notch, such as image 3 shown. These four regions are defined clockwise as the first region 311, the second region 312, the third region 313, and the fourth region 314; The direction perpendicular to the first direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com