Detecting and recycling device for abandoned polishing sheets

The technology of a recycling device and a recycling bucket is applied in the field of detection and recycling devices for discarded grinding discs, which can solve the problems of waste of resources, random discarding of discarded grinding discs, etc., and achieve the effects of preventing waste of resources, preventing random discarding, and detecting and recycling work efficiently.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The device for detecting and recovering waste grinding sheets according to the present invention will be further described in detail through specific embodiments below.

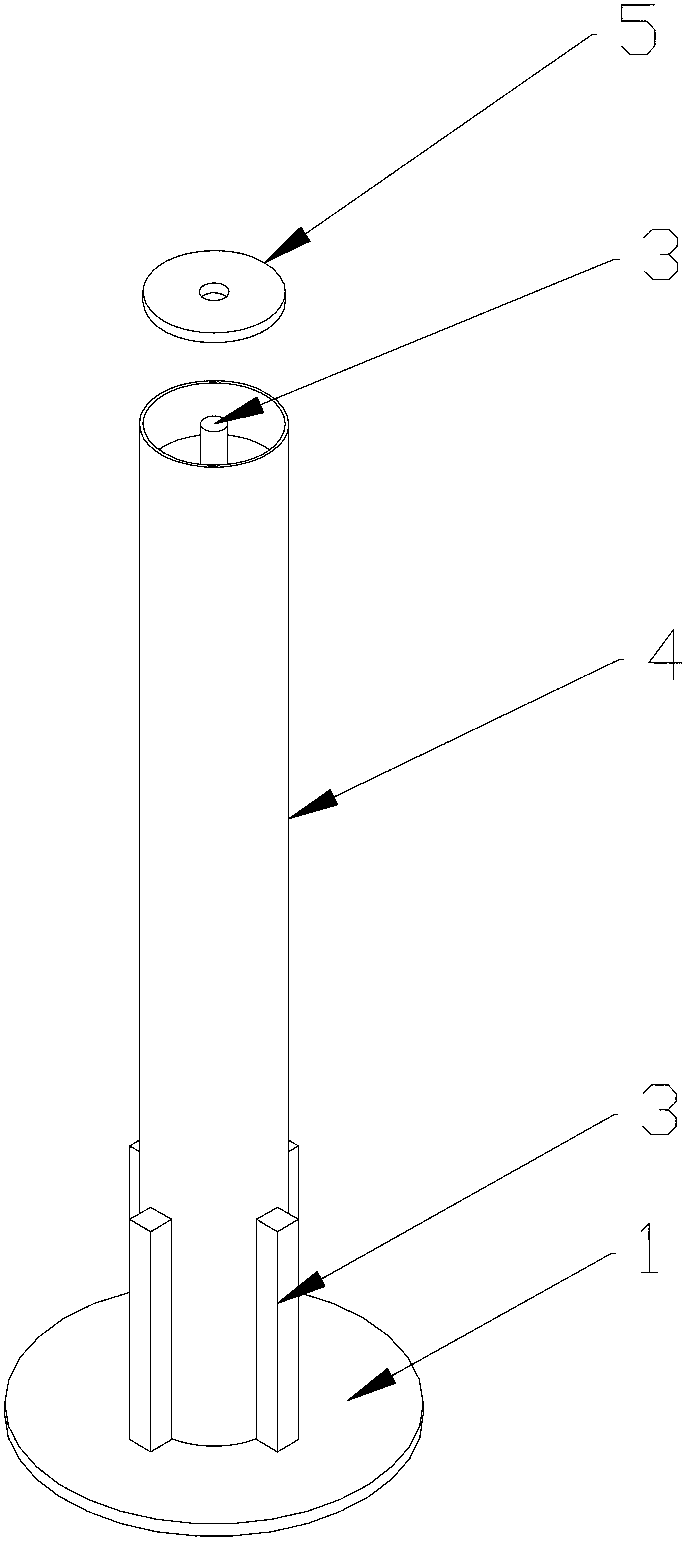

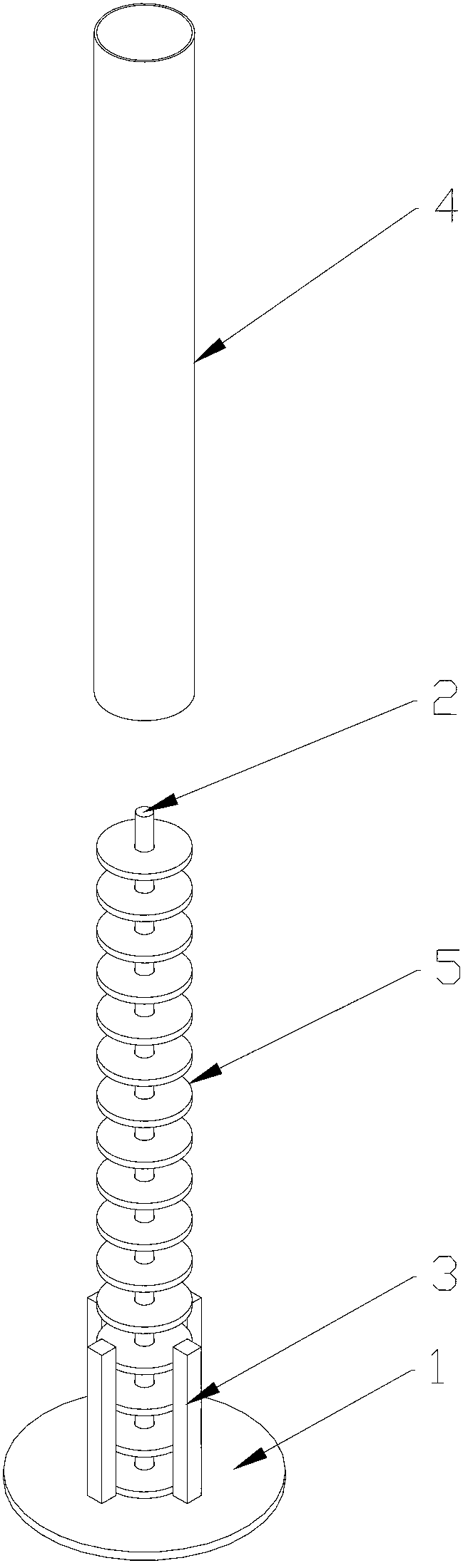

[0017] like figure 1 As shown, a waste grinding sheet detection and recovery device includes a base 1, a waste grinding sheet installation shaft 2 and at least three limit shafts 3, and the waste polishing sheet installation shaft 2 and at least three limit shafts 3 are all installed on the base 1, Each limit shaft 3 is distributed around the installation shaft 2 of the discarded grinding sheet.

[0018] Preferably, the distances between each limit shaft 3 and the waste grinding sheet installation shaft 2 are the same, and each limit shaft 3 is evenly distributed around the waste grinding sheet installation shaft 2 .

[0019] In this embodiment, there are four limit shafts 3, and the detection recovery device also includes a detection recovery bucket 4, the detection recovery bucket 4 is cylindrical, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com