A cassette and a device for transporting glass substrates

A technology for glass substrates and cassettes, applied in the directions of transportation and packaging, packaging, packaging items, etc., can solve the problems that the glass substrates 8 are prone to deflection, scratches, collisions, and vibrations, etc. The effect of improving safety and avoiding injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

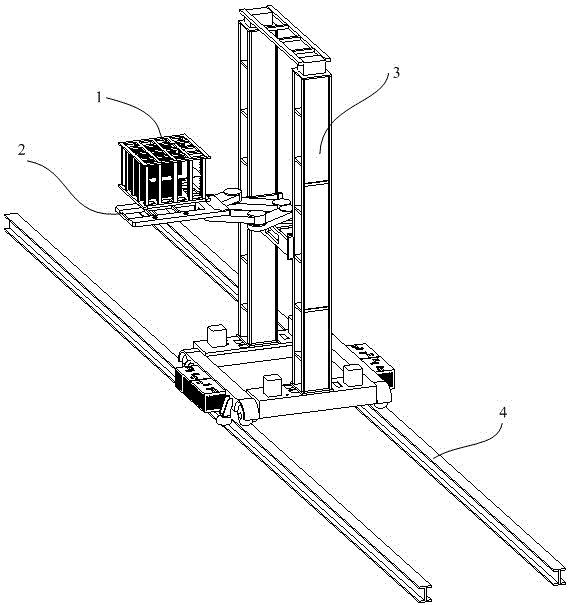

[0035] Such as figure 2 Shown is a schematic structural view of an embodiment of a device for handling glass substrates according to the present invention; in this embodiment, the device for handling glass substrates includes:

[0036] The stacker 3, which can slide on the guide rail 4, is responsible for transporting the cassettes 1 in the storage position between the interior of the automatic storage system; specifically, it can move along the guide rail to a designated storage position or process temporary storage The port (EQport) is used to access the cassette 1 in the storage location, and can transport the cassette 1 to other storage locations or process temporary storage ports.

[0037] The handling mechanism 2 is used to pick and place the cassette 1 in the storage position, which is arranged on the stacker 3, can move vertically on the stacke...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap