Micro-polluted water in-situ remediation system

An in-situ remediation, micro-pollution technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve micro-polluted water waste, easy secondary pollution, complex management, etc. problems, to achieve the effect of saving cost, reducing floor space and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

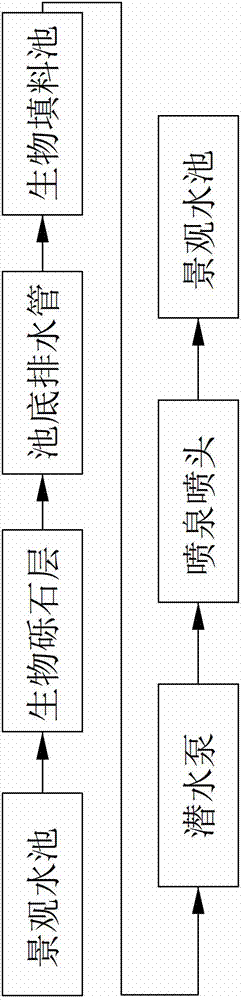

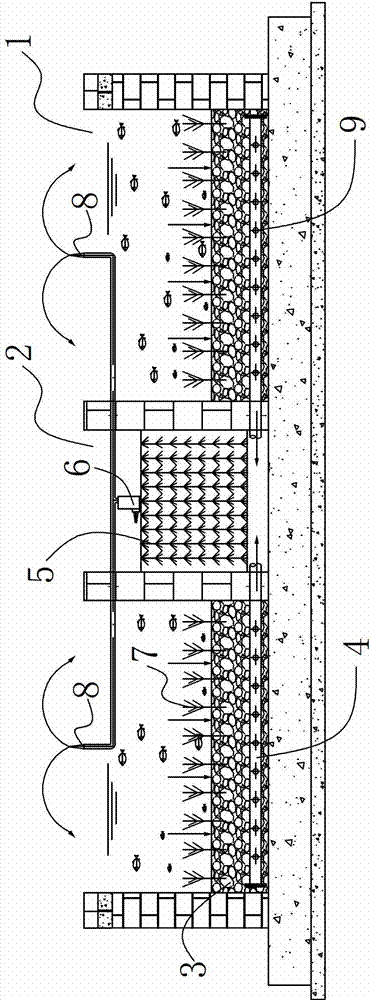

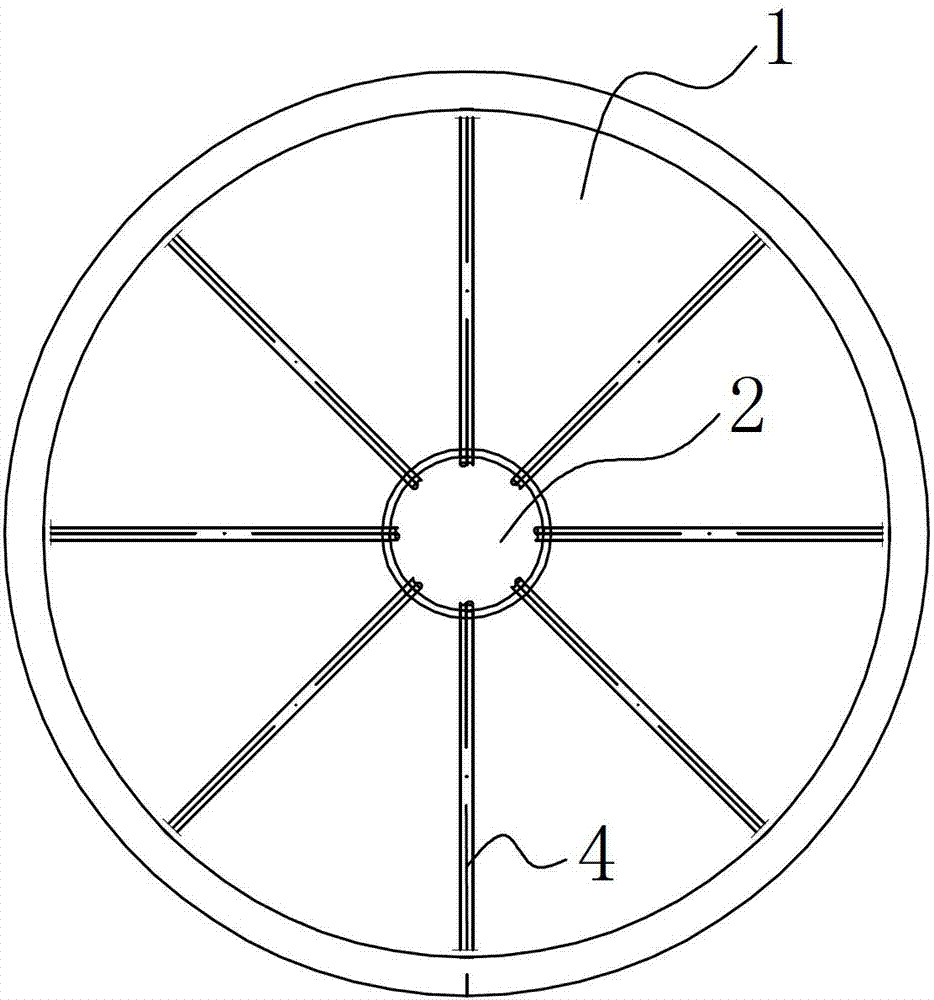

[0020] refer to Figure 1 to Figure 3 , an in-situ remediation system for slightly polluted water bodies of the present invention includes a pool 1, and a biological filler pool 2 separated from the pool 1, and the biological filler pool 2 is also called a filler biochemical pool. The bottom of the pool 1 is provided with a bio-gravel layer 3 of a certain height, and the bottom of the bio-gravel layer 3 is provided with a bottom drain pipe 4 leading water to the bottom of the bio-fill pool 2, and the bio-fill pool 2 is provided with a water body To purify the biological filler 5 with high specific surface area of the growth and reproduction carrier of exclusive microbial strains, the upper part of the biological filler pool 2 is provided with a submersible pump 6 that transports the treated clean water back to the pool 1 .

[0021] As the carrier for the growth and reproduction of exclusive microbial strains for water purification, the biological filler 5 forms a complex met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com