A method for filtering and purifying waste water containing silicon powder

A technology for filtration purification and treatment methods, applied in chemical instruments and methods, filtration separation, separation methods, etc., can solve the problems of large environmental impact, inconvenient pressure treatment, high water turbidity, and achieve simple equipment operation and structure, water quality. The effect of good purification and short pre-filming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

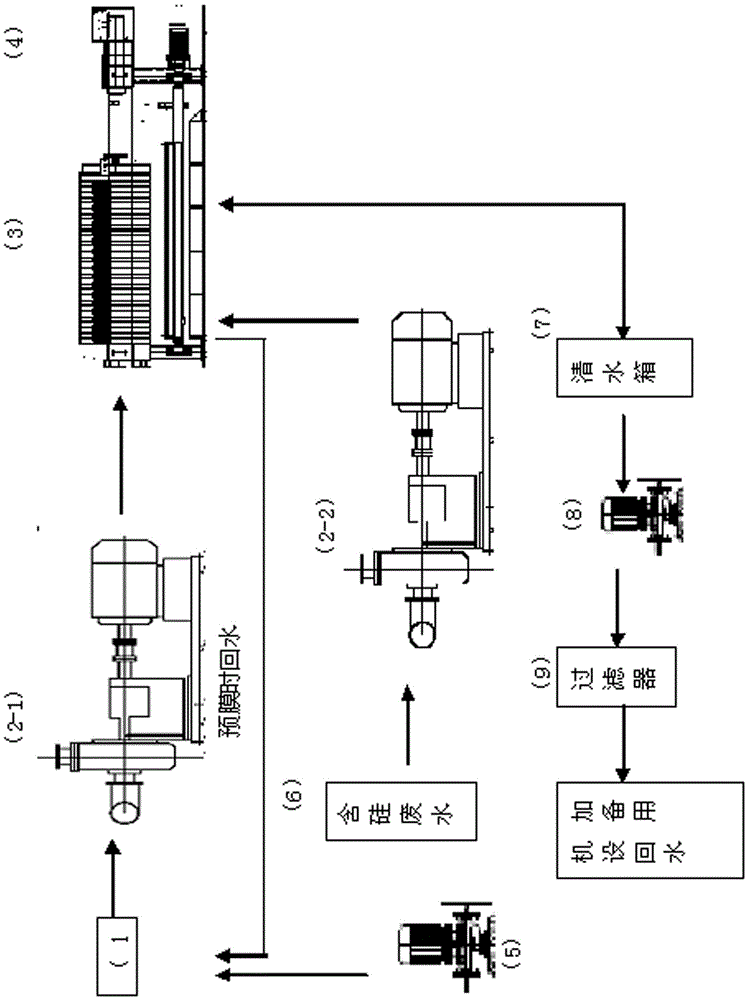

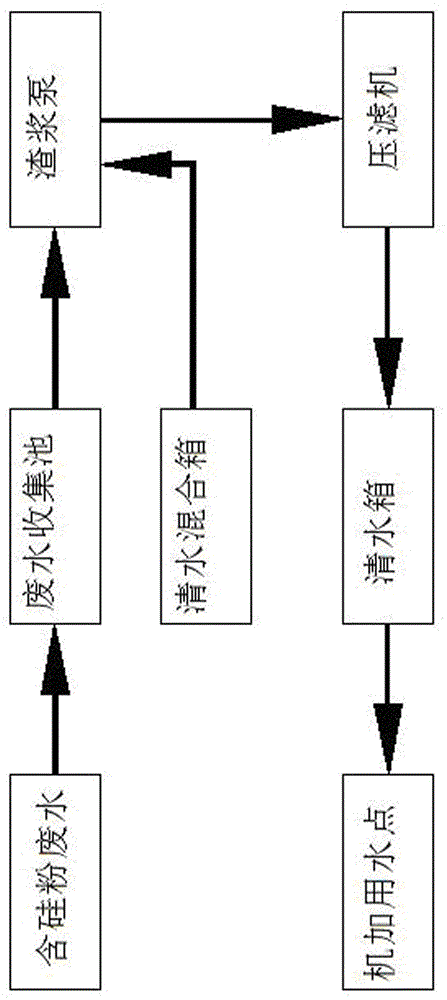

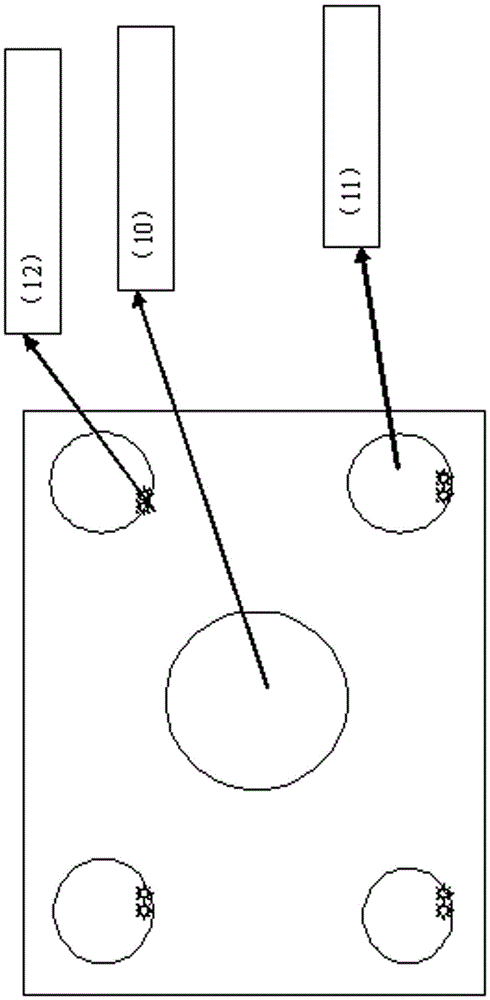

Method used

Image

Examples

Embodiment 1

[0029] Filter area of filter press: 15-30㎡; pressure of hydraulic cylinder of filter press: 20Mpa. As the working time continues, as the attachments on the filter cloth increase, the pressure of hydraulic cylinder of filter press will increase slowly. If the pressure of the hydraulic cylinder is higher than 28MPa, if you continue to work, because the filter cloth has a tendency to block, the hydraulic cylinder will generate high pressure instantaneously, resulting in hidden dangers of equipment safety accidents. Therefore, attention should be paid to monitoring the pressure of the hydraulic cylinder of the filter press during work (not higher than 28MPa); processing capacity: the maximum processing capacity is 30m3 in 3 hours (because this method treats silicon-containing wastewater, the flow rate is a large change Small gradual change process, within a certain period of time, only the total amount of treatment can be seen, but a constant flow cannot be obtained) The flow is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com