Efficient environment-friendly pre-filming agent

A kind of pre-filming agent and environmental protection technology, applied in the direction of metal material coating process, etc., can solve the problems of direct discharge that cannot achieve environmental protection, eutrophication of water polluted water, high phosphorus content, and achieve remarkable pre-filming effect and pre-filming effect. Good, the effect of shortening the pre-filming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

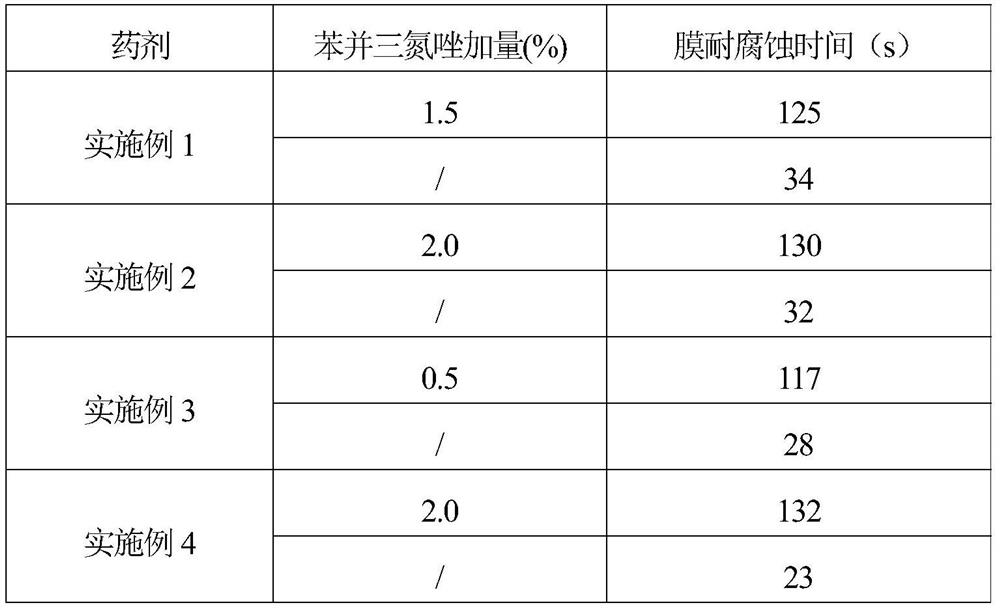

Embodiment 1

[0017] Add 250g of acrylic acid-acrylate-sulfonate copolymer, 20g of sodium gluconate, 70g of zinc chloride, 15g of benzotriazole, and 5g of concentrated sulfuric acid into 640g of water in sequence, and stir evenly to obtain a prefilm agent.

Embodiment example 2

[0019] Add 280g of acrylic acid-acrylate-sulfonate copolymer, 50g of sodium gluconate, 50g of zinc chloride, 20g of benzotriazole, and 10g of concentrated sulfuric acid into 590g of water in sequence, and stir evenly to obtain a prefilm agent.

Embodiment example 3

[0021] Add 300g of acrylic acid-acrylate-sulfonate copolymer, 70g of sodium gluconate, 60g of zinc chloride, 5g of benzotriazole, and 15g of concentrated sulfuric acid into 550g of water in sequence, and stir evenly to obtain a pre-film agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com