System of taking residual ammonia water as cooling circulating supplementing water

A cooling cycle, cooling water technology, applied in water/sewage multi-stage treatment, biological water/sewage treatment, heating water/sewage treatment, etc. , to achieve the effect of solving the problem of wastewater treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

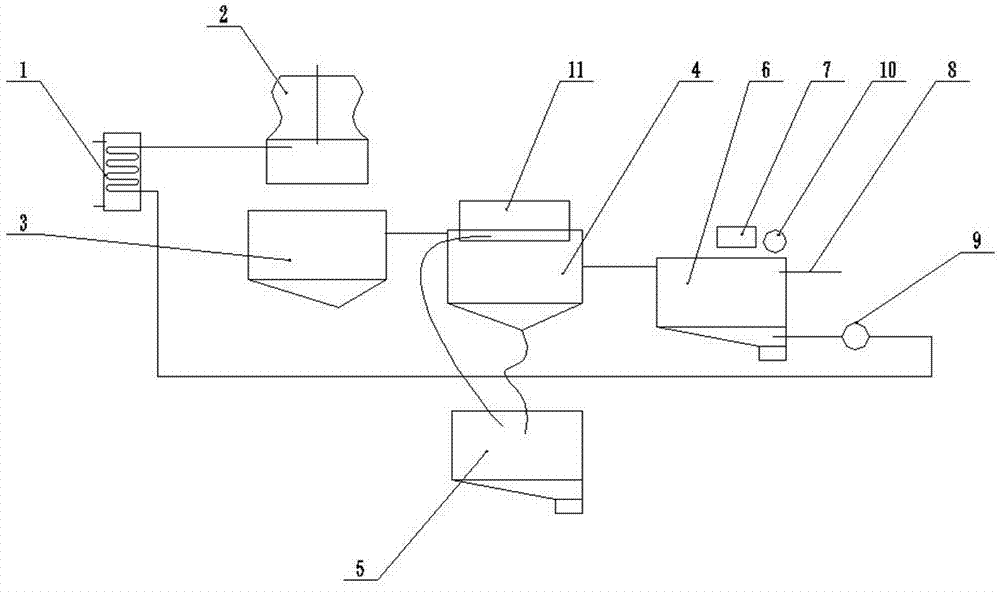

[0022] like figure 1 Shown, a kind of system that utilizes surplus ammonia water as cooling cycle replenishment water, comprises heat exchange device 1, cooling tower 2, sump tank 3, middle settling tank 4, sludge tank 5, make-up water tank 6, filtration equipment 7, described cooling The tower 2 is arranged above the sump 3, the cooling water coming out from the heat exchange device 1 enters the cooling tower 2, the cooling water coming down from the cooling tower 2 enters the sump 3, and the cooling water from the sump 3 The cooling water overflowed enters the middle sedimentation tank 4, and the cooling water flowing out from the overflow pipe of the middle sedimentation tank 4 enters the replenishment pool 6;

[0023] The replenishment pool 6 is also connected to one or several pipelines 8 of remaining ammonia water or other industrial waste water or domestic sewage, and the remaining ammonia water or other industrial waste water or domestic sewage enters the replenishment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com