Low-phosphorous pre-film former used for industrial circulating cooling water system pipeline and heat exchanger

A technology of circulating cooling water and heat exchangers, applied in the coating process of metal materials, etc., can solve the problems of poor prevention of electrochemical corrosion and under-deposit corrosion, inability to effectively remove rust and scale, and shorten the service life of equipment , to achieve the effect of good operating conditions, good pre-film effect, and guaranteed use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

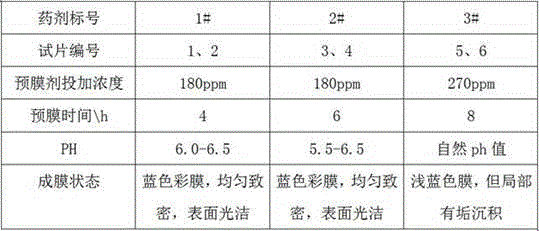

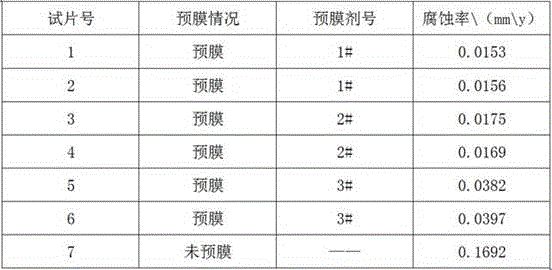

Examples

Embodiment 1

[0012] A low-phosphorus pre-coating agent for industrial circulating cooling water system pipelines and heat exchangers, comprising the following raw materials in proportions by weight: 10 parts of 2-phosphonic acid butane-1,2,4-tricarboxylic acid, hydroxyl 6 parts of phosphonoacetic acid, 8 parts of acrylic acid-hydroxypropyl acrylate-AMPS terpolymer, 6 parts of hydrolyzed polymaleic anhydride, 13 parts of zinc sulfate heptahydrate, 2 parts of methyl benzotriazole and 0.5 parts of sodium gluconate Parts, hydrolyzed polymaleic anhydride is a low molecular weight polyelectrolyte, generally with a relative molecular weight of 400-800, non-toxic, easily soluble in water, high chemical and thermal stability, and the decomposition temperature is above 330 °C.

[0013] A low-phosphorus pre-film agent for industrial circulating cooling water system pipelines and heat exchangers, comprising the following steps: sequentially adding 10 parts of 2-phosphonic acid butane-1,2,4-tricarboxyli...

Embodiment 2

[0015] A low-phosphorus pre-coating agent for industrial circulating cooling water system pipelines and heat exchangers, comprising the following raw materials in proportions by weight: 10 parts of 2-phosphonic acid butane-1,2,4-tricarboxylic acid, hydroxyl 8 parts of phosphonoacetic acid, 8 parts of acrylic acid-hydroxypropyl acrylate-AMPS terpolymer, 8 parts of hydrolyzed polymaleic anhydride, 14 parts of zinc sulfate heptahydrate, 2 parts of methyl benzotriazole and 1 part of sodium gluconate Parts, hydrolyzed polymaleic anhydride is a low molecular weight polyelectrolyte, generally with a relative molecular weight of 400-800, non-toxic, easily soluble in water, high chemical and thermal stability, and the decomposition temperature is above 330 °C.

[0016] A low-phosphorus pre-film agent for industrial circulating cooling water system pipelines and heat exchangers, comprising the following steps: sequentially adding 10 parts of 2-phosphonic acid butane-1,2,4-tricarboxylic a...

Embodiment 3

[0018] A low-phosphorus pre-coating agent for industrial circulating cooling water system pipelines and heat exchangers, comprising the following raw materials in proportions by weight: 8 parts of 2-phosphonic acid butane-1,2,4-tricarboxylic acid, hydroxyl 6 parts of phosphonoacetic acid, 6 parts of acrylic acid-hydroxypropyl acrylate-AMPS terpolymer, 6 parts of hydrolyzed polymaleic anhydride, 13 parts of zinc sulfate heptahydrate, 1 part of methyl benzotriazole and 0.5 parts of sodium gluconate Parts, hydrolyzed polymaleic anhydride is a low molecular weight polyelectrolyte, generally with a relative molecular weight of 400-800, non-toxic, easily soluble in water, high chemical and thermal stability, and the decomposition temperature is above 330 °C.

[0019] A low-phosphorus pre-filming agent for industrial circulating cooling water system pipelines and heat exchangers, comprising the following steps: sequentially adding 8 parts of 2-phosphonic acid butane-1,2,4-tricarboxyli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com