Gravity-driven drinking water purification device based on near-zero operation and maintenance double-membrane method and method for treating distributed source water by using gravity-driven drinking water purification device

A gravity-driven, purification device technology, applied in the direction of sterilization/microdynamic water/sewage treatment, multi-stage water treatment, water/sewage treatment, etc., can solve pollution and other problems, achieve simple operation, reduce production volume, and improve water quality safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

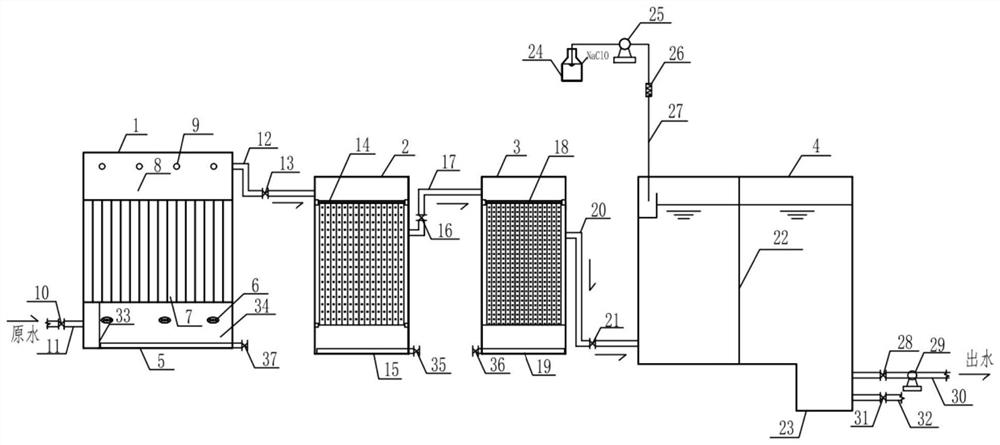

[0023] Specific Embodiment 1: In this embodiment, a gravity-driven drinking water purification device based on a near-zero operation and maintenance double-membrane method includes a three-phase flow high-speed sedimentation tank 1, a cleaning-free microfiltration membrane tank 2, and a gravity-driven ultrafiltration membrane tank 3 And high-efficiency mixed disinfection pool 4;

[0024] The water inlet pipe 11, the high-efficiency rapid sedimentation tank 1, the no-cleaning microfiltration membrane tank 2, the gravity-driven ultrafiltration membrane tank 3, the high-efficiency mixing disinfection tank 4 and the outlet pipe 30 are connected in sequence.

specific Embodiment approach 2

[0025] Specific embodiment two: the difference between this embodiment and specific embodiment one is: one end of the three-phase flow high-speed sedimentation tank 1 communicates with the raw water through the water inlet pipe 11, and the other end of the three-phase flow high-speed sedimentation tank 1 passes through The outlet pipe 12 is connected to one end of the no-cleaning microfiltration membrane pool 2, and the other end of the no-cleaning microfiltration membrane pool 2 is connected to one end of the gravity-driven ultrafiltration membrane pool 3 through the microfiltration water production pipe 17, and the gravity-driven ultrafiltration membrane The other end of the pool 3 communicates with one end of the high-efficiency mixing disinfection pool 4 through the ultrafiltration membrane water production pipe 20, and the other end of the high-efficiency mixing disinfection pool 4 communicates with the outlet pipe 30 through the sump 23 at the bottom. Other steps are the ...

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is: the three-phase flow high-efficiency rapid sedimentation tank 1 includes the sewage pipe 5 of the rapid sedimentation tank, the sewage valve 37, the water distribution wall 33, the gas release 6, three-phase flow rate immersed tube 7 and evenly distributed perforated water collection pipe 9; the water distribution wall 33 is arranged at the water inlet of the three-phase flow high-speed sinking tank 1, and multiple rows of small holes are arranged on the water distribution wall 33 to achieve uniform water distribution Function, the material of the three-phase flow rate immersed tube 7 can be steel pipe or plastic tube, the inner wall is rough, which is easy to attach biofilm, and the inside of the tube is a gas-liquid-solid three-phase mixed flow, and the water flow, gas and biofilm work together in the three-phase flow rate immersed tube 7 , simultaneously realize particulate matter, organic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com