Dot-matrix remediation system for non-point source polluted water treatment and working method of dot-matrix remediation system

A non-point source pollution and repair system technology, which is applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve problems such as limited effect of polluted water treatment technology and unstable operation , to achieve the effect of long-term degradation of sediment pollution, efficient purification of water bodies, and improvement of water body landscape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

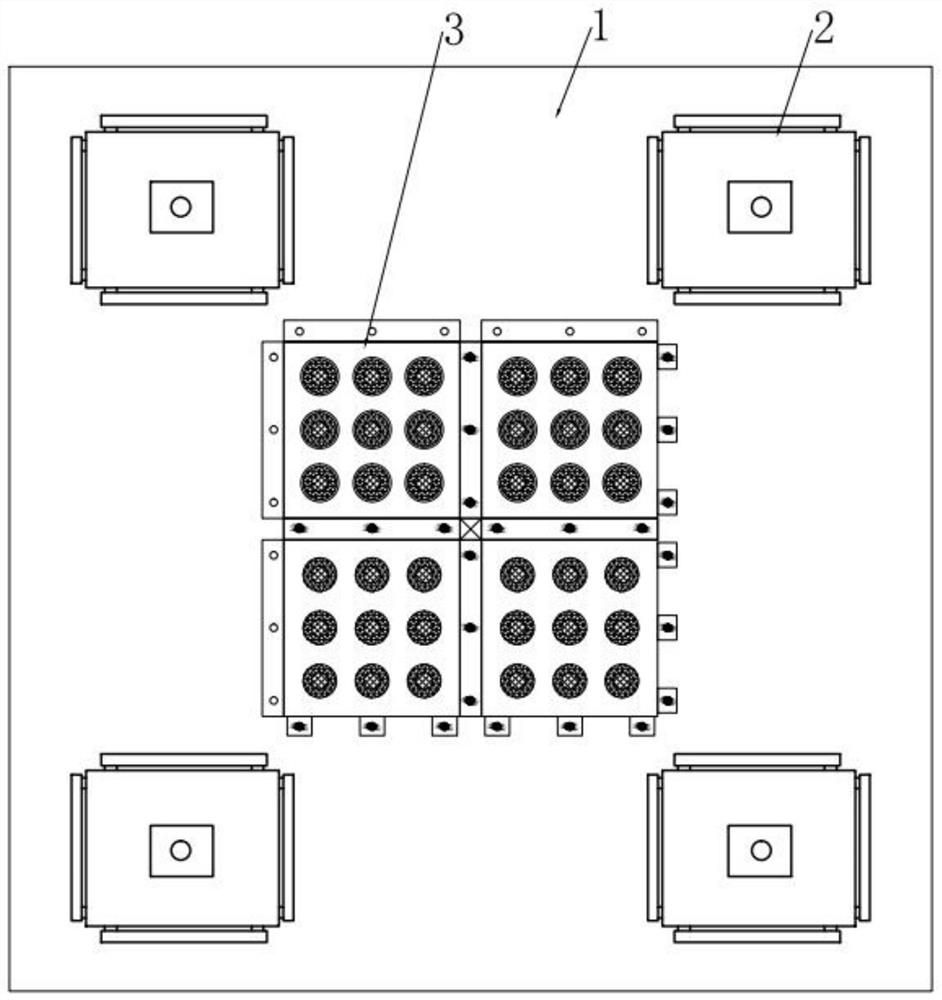

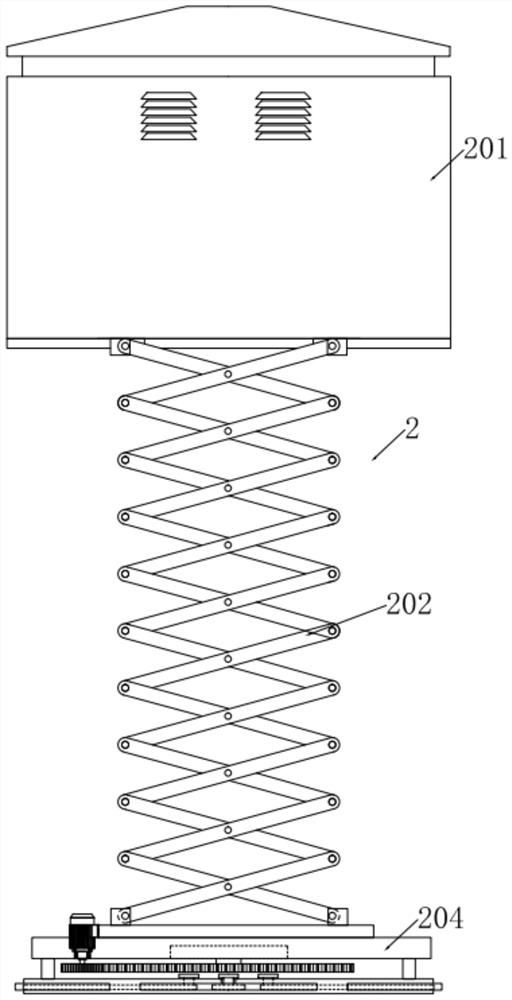

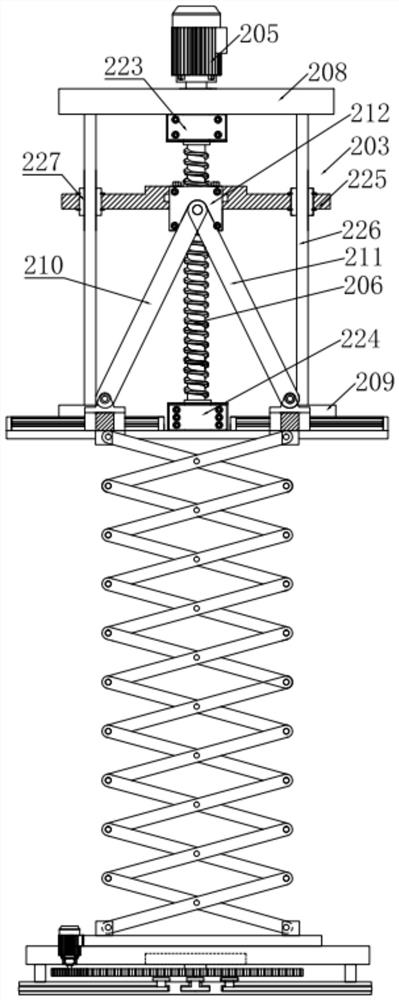

[0055] Such as figure 1 The shown lattice repair system for surface source polluted water treatment includes a square floating hull 1, four aeration robots 2 and plant blankets 3, and the four aeration robots 2 are respectively arranged on the four sides of the square floating hull 1. On the corner, the plant blanket 3 is arranged at the center of the square floating hull 1; wherein, the aeration robot 2 includes a box body 201, a scissor assembly 202, a scissor lifting drive device 203 and an aeration device 204, so The box body 201 and the scissor lift drive device 203 are all arranged on the square floating hull 1, and the scissor lift drive device 203 is arranged in the range covered by the box body 201, the scissor assembly 202 and the scissor lift drive The device 203 is connected, and the scissors lifting drive device 203 can drive the scissors assembly 202 to expand or contract, and the aeration device 204 is connected to the lower end of the scissors assembly 202 .

...

Embodiment 2

[0059] Such as Figure 8-10 The shown aeration device 204 includes an aeration support plate 228, an aeration installation assembly 229, a support plate 230, an aeration drive assembly 231 and a set of aeration heads 232, the aeration support plate 228 and the scissor assembly 202 The lower end is hinged, the support plate 230 is connected to the aeration support plate 228, and the support plate 230 is located below the aeration support plate 228, and a group of aeration heads 232 are arranged on the aeration installation assembly 229, the aeration The drive assembly 231 is arranged on the aeration support plate 228, and the aeration drive assembly 231 is connected with the aeration installation assembly 229, and the aeration installation assembly 229 is slidably connected with the support plate 230, and the aeration installation assembly 229 and the aeration drive The component 231 is connected, and the aeration driving component 231 can drive the aeration installation compon...

Embodiment 3

[0064] Such as Figure 11-18 The plant blanket 3 shown is composed of a group of plant blanket body modules 30, the cross section of the group of plant blanket body modules 30 is in the positive direction, and the plant blanket body modules 30 are spliced with each other in a rectangular array to form a plant blanket; Wherein, the plant blanket body module 30 includes a cultivation frame 301 and two connection plates 302, the section of the cultivation frame 301 is a square, and the two connection plates 1 302 are arranged on two adjacent sides of the cultivation frame 301 On the cultivation frame 301, a group of connection assemblies 303 are arranged on the two sides opposite to the connection plate 302, and the connection assembly 302 of the cultivation frame 301 is connected to the connection assembly on the adjacent cultivation frame 301. 303 connection. The first connecting plate 302 is in the shape of a rectangular plate, and the set of connecting components 303 is ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com