Test device for the characteristics of the joint surface of the ball and the raceway

A technology for testing devices and joint surfaces, which is applied in the testing of machines/structural components, measuring devices, testing of mechanical components, etc., and can solve problems such as difficulties in testing contact characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

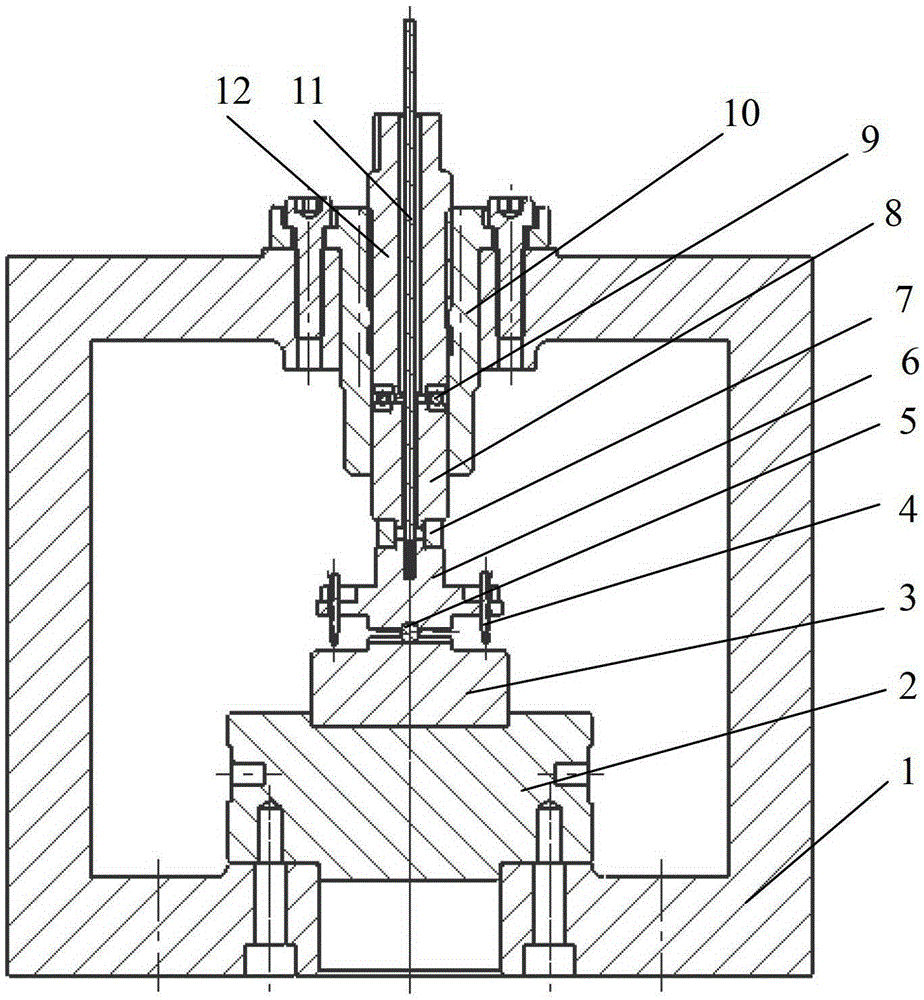

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

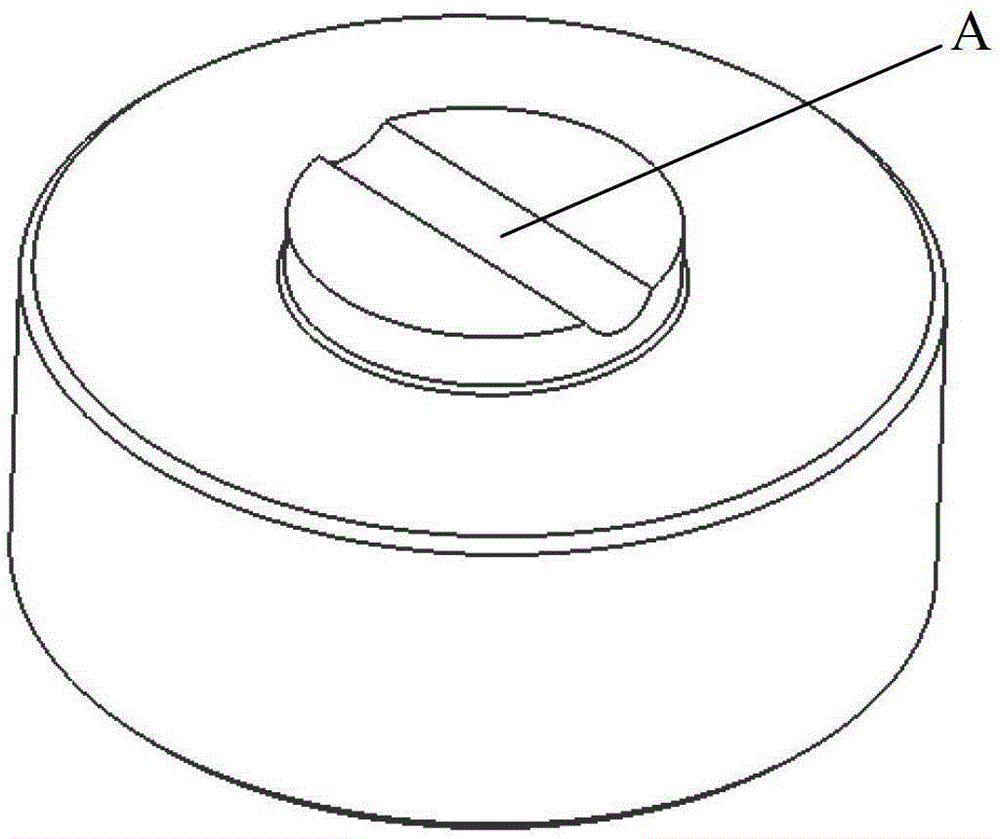

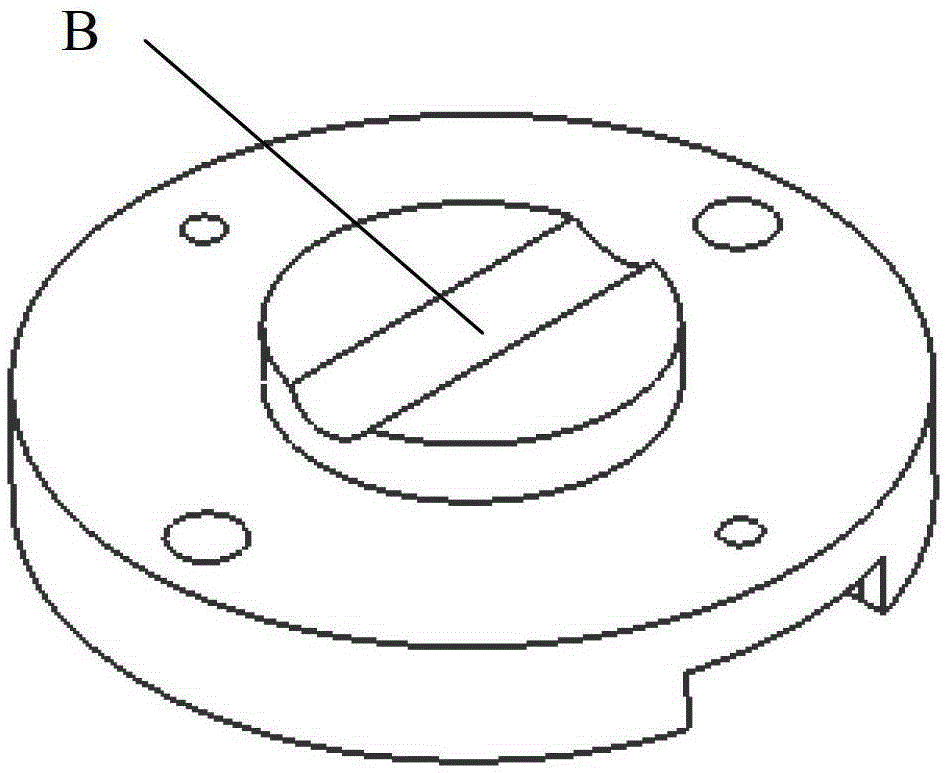

[0022] The test device for the characteristics of the joint surface of the ball and the raceway includes an upper test piece 6 and a lower test piece 3, each of which is provided with a semi-cylindrical raceway, and the upper test piece 6 and the lower test piece The less semi-cylindrical raceways on the top 3 are placed perpendicular to each other, the ball 5 is placed between the less semi-cylindrical raceways of the upper test piece 6 and the lower test piece 3, and the raceways pass through the upper test piece 6 and the displacement sensor 4 and the force sensor 7 connect.

[0023] The upper test piece 6 and the lower test piece 3 are cylindrical and arranged coaxially. A few semi-cylindrical raceways are arranged in the middle of the upper test piece 6 and the lower test piece 3, and both sides are symmetrical.

[0024] A load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com