Lens cover turning-over fatigue testing machine for visor

A fatigue testing machine and sun visor technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of difficulty in controlling air volume, waste of cost, time and resources, and uneven force, and improve the testing ability. and test efficiency, save test time, and use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

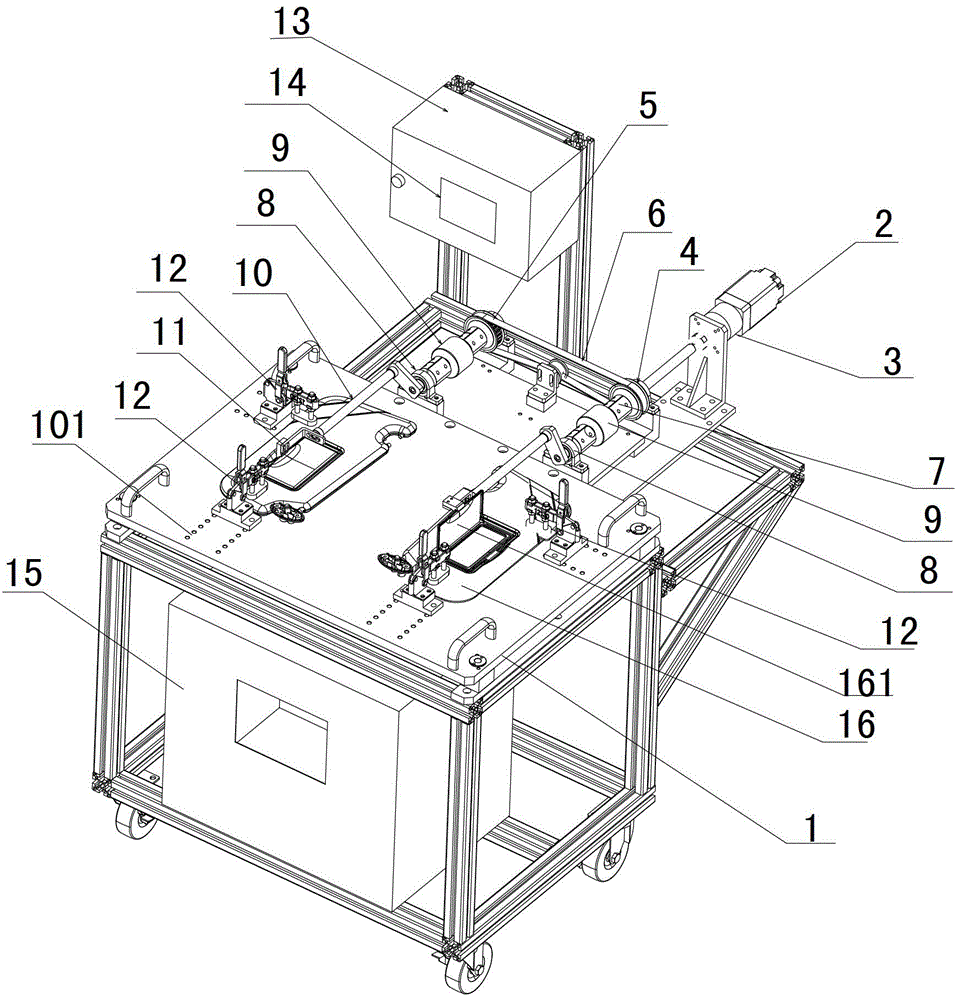

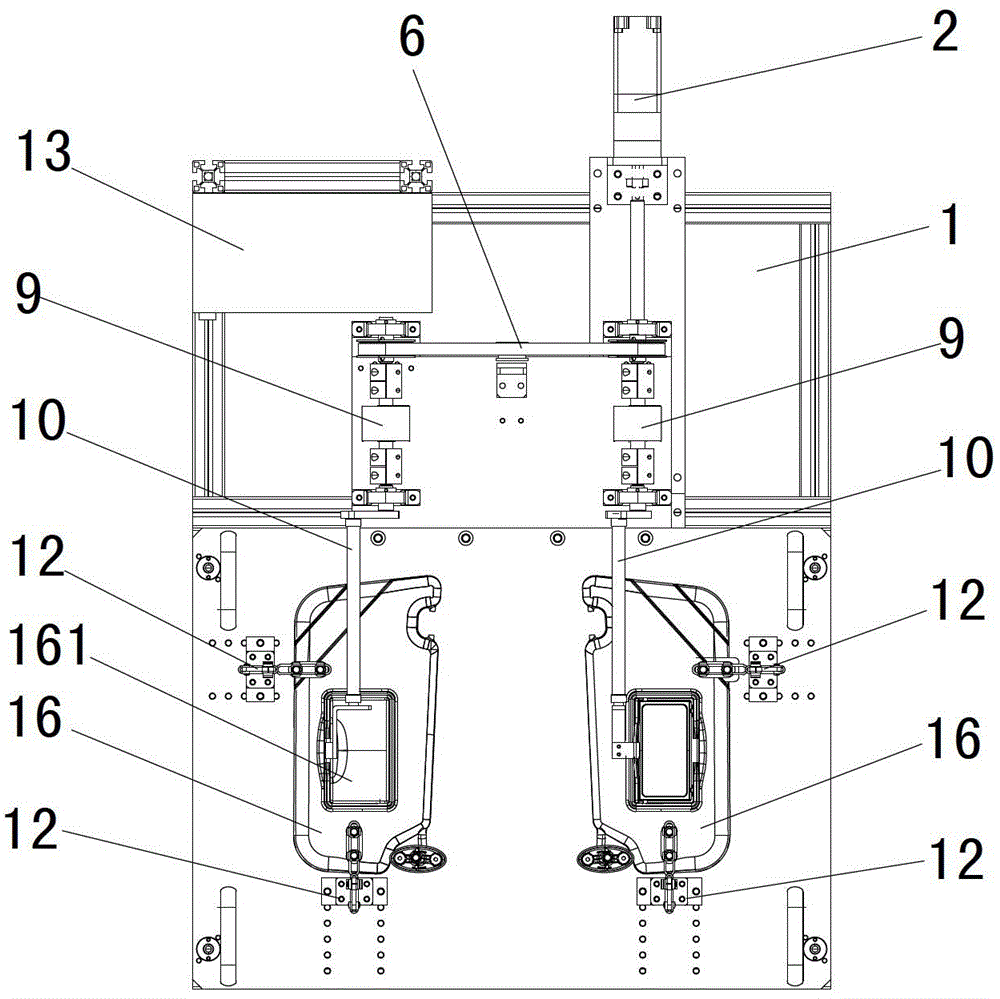

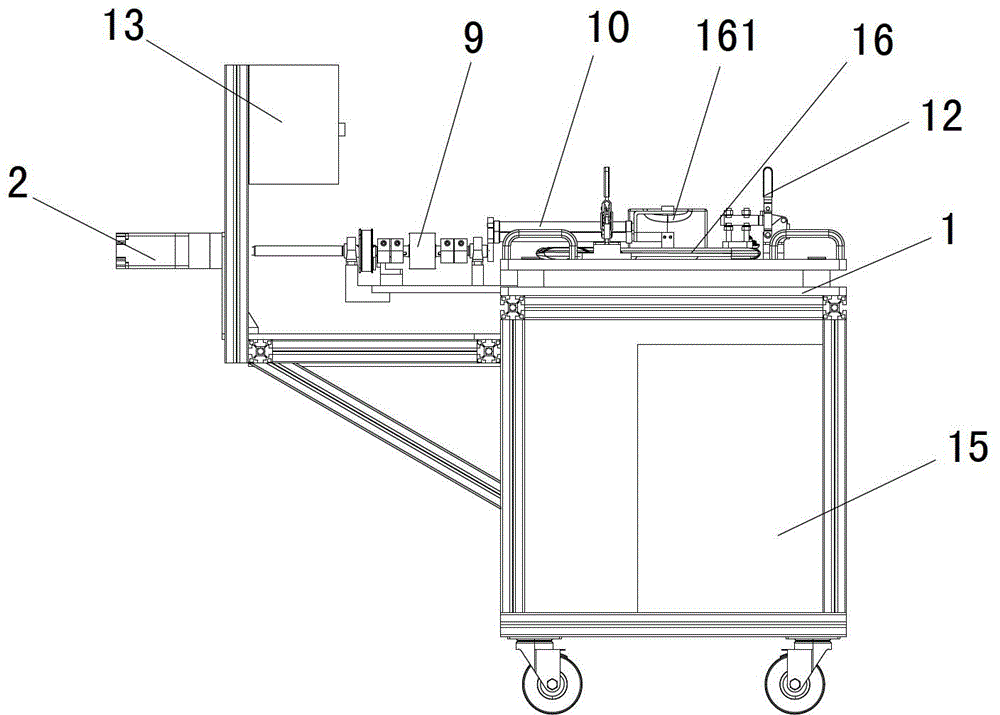

[0028] see figure 1 , figure 2 , image 3 , the sun visor mirror cover flipping fatigue testing machine of the present invention comprises a machine platform 1 on which an electric mechanism, a transmission mechanism, two ball bearing mechanisms with sensors, two ball bearing mechanisms with sensors, two Mirror cover turning mechanism, sun visor pressing mechanism, PLC, touch screen and industrial computer.

[0029] The electric mechanism includes a servo motor 2 and a speed reducer 3, and its power output shaft is connected with the driving transmission gear 4 in transmission.

[0030] The transmission mechanism includes a driving transmission gear 4, a driven transmission gear 5 and a transmission gear belt 6 connected between the two transmission gears, and the driving transmission gear 4 is connected with the power output shaft of the electric mechanism.

[0031] The two ball bearing mechanisms with sensors each include a rotating shaft 7, a ball bearing 8 and a tensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com